Hello Pinger

You write:

“18% more piston travel propelled by an average of say 2bar pressure. The torque gain will be slight.”

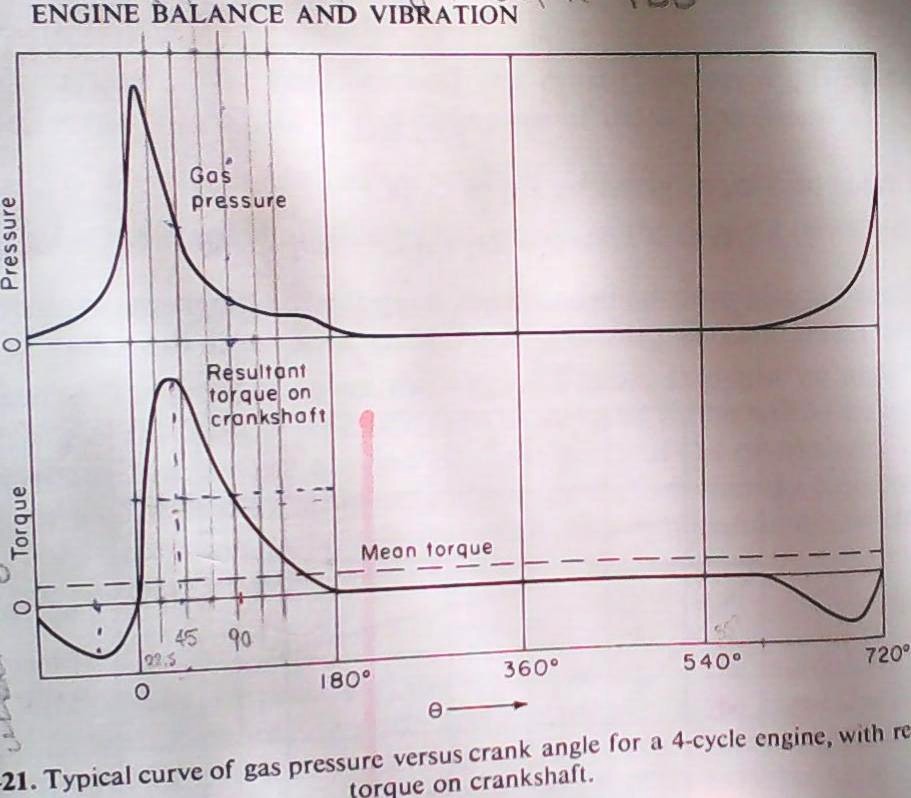

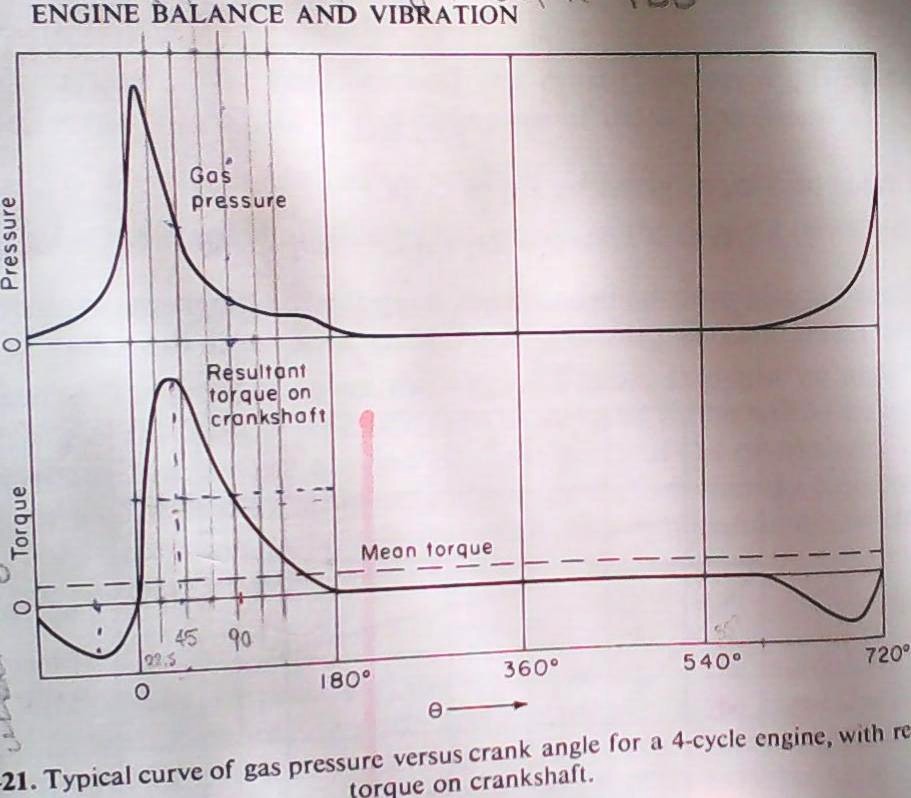

Here is the pressure (and the torque) versus the crankshaft angle of a typical 4-stroke engine:

It is from Taylor’s book “The Internal Combustion Engine in Theory and Practice”.

After the closing of the ports a 2-stroke gives a quite similar plot.

Spot on the pressure at 90 crank degrees. It is about 1/6 of the peak pressure. Nothing to do with 2 bars.

Spot on the torque at 90 degrees.

While at 90 degrees after the TDC the pressure is several times lower than the peak pressure, at the same 90 degrees the eccentricity of the connecting rod from the crankshaft axis maximizes, explaining how, with six times lower pressure, the torque at 90 degrees is only two times lower than the peak torque.

The mechanical energy provided by the engine during the rotation of the crankshaft from an angle f to an angle f+df equals to the torque (at the angle f) times the angle differential df.

The total mechanical energy provided to the crankshaft from 0 degrees to 180 degrees equals to the area underside the torque curve, which is about equal to the torque at 90 degrees times 180 degrees (according the plot of Taylor, the torque at 90 degrees is about the mean torque during the expansion stroke).

About one quarter of this mechanical energy is consumed during the compression stroke (torque curve before the TDC).

According the previous, extending the expansion from 80 degrees after the TDC (RD350LC) to 90 degrees after the TDC (PatATE), another 6% of mechanical energy arrives to the crankshaft during the expansion stroke.

And because the compression is already "paid", this 6% is "clean", which means the mechanical energy to the crankshaft (as well as the power of the engine) increases by some 8%.

An 8% increase of the power and of the torque (and of the mileage etc) cannot be considered as insignificant.

As for the above rough calculations, they favor the conventional, not the PatATE.

You also write:

“Despite the valve opening the port very fast - is the port not still obscured by the piston?”

No.

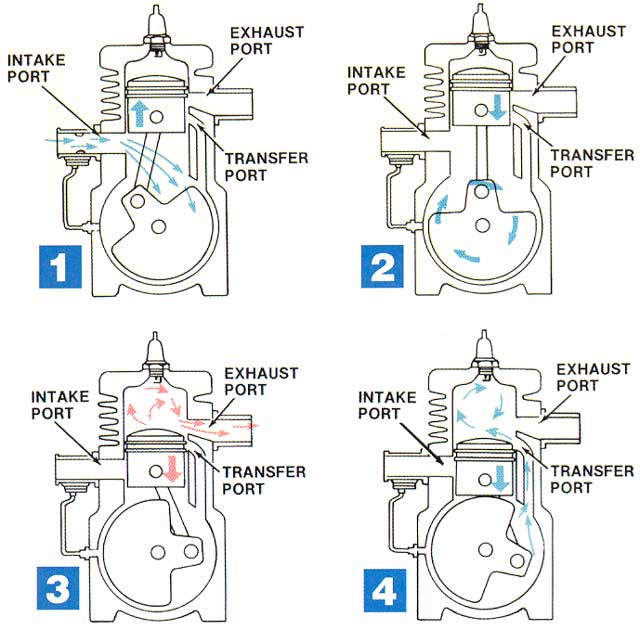

It is not the valve that opens the hybrid port.

Several degrees before the piston starts opening the hybrid port, the rotary valve has uncovered the outer side of the hybrid port.

See the following animation.

Spot on the hybrid port and on the rotary valve when the piston is around the TDC: the piston keeps the hybrid port closed, however the rotary valve keeps rotating to get at the right angle / position when the piston will start opening the hybrid port.

Quote from

http://www.pattakon.com/pattakonPatATE.htm (near the end of the web page):

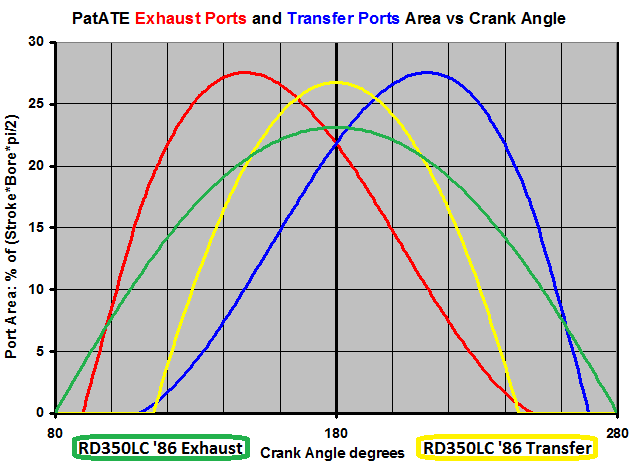

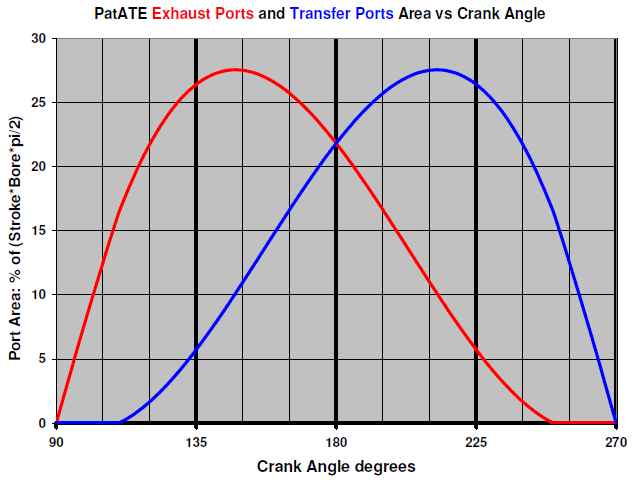

Rate of Exhaust Opening and of Transfer Closing

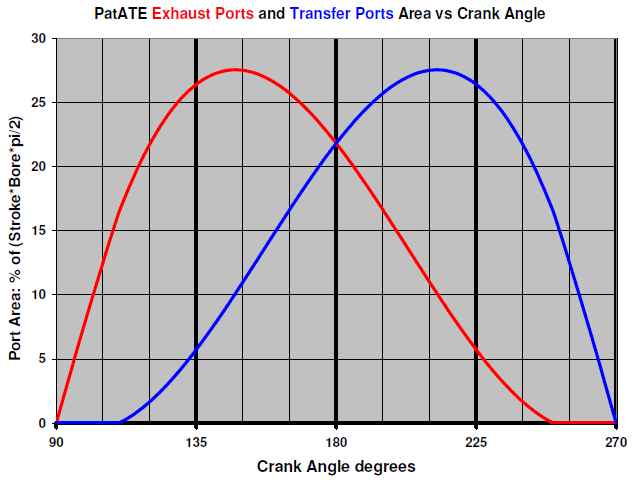

In the following graph it is shown the Exhaust Port area and the Transfer Port area versus the crank angle:

In the following animation it can be seen the position of the rotary valve of the PatATE just before the opening of the hybrid port by the piston.

During the compression and the expansion the rotary valve keeps rotating.

At the beginning of the exhaust the outer side of the hybrid port is fully "uncovered" by the rotary valve, so that the complete hybrid port is dedicated to the exhaust.

The rate of the exhaust opening is about double as compared to the rate of the exhaust opening in a similar conventional 2-stroke.

According the Yamaha RD350LC port-map (click

http://www.pattakon.com/tempman/Yamaha_ ... rt_map.jpg to download), the exhaust port extends on the periphery of the cylinder liner for some 80 degrees while the hybrid port of a similar PatATE extends along the periphery of the cylinder liner for nearly 180 degrees.

The graph at

http://www.pattakon.com/tempman/PatATE_ ... orting.png shows the difference.

With similar timing with a conventional, the blow down of the PatATE is substantially faster.

For similar blow down, the PatATE needs substantially more conservative timing (which also means longer expansion, more power and torque, better fuel efficiency etc)..

End of Quote

If something is confusing, please let me know to further explain.

Thanks

Manolis Pattakos