The optimum bore to stroke ratio for the 2-strokes is 1.0 or very close to it (square design).

The four strokes (say, the Ducati Panigale 1299) use substantially bigger bore to stroke ratios (Panigale: 116mm bore, 60.8mm stroke, bore to stroke ratio 1.91).

Bigger bore means bigger valves and so freer breathing and more power at higher revs, it also means smaller inertia loads, lower friction, etc.

In Ducati they exploited their key advantage (the desmodromic valve train) and pushed farther the limits of the oversquare design.

20 years ago a sport motorcycle having more than 2.0 bore to stroke ratio would seem a bad choice, a mistake; today it seems quite reasonable (the expensive Panigale 1299 uses 1.9 bore to stroke ratio and is regarded one of the best engines).

How the previous are translated in specific power? (say, ratio of power to displacement, like PS per cc)

To make it more specific.

Take a 125cc 2-stroke. Square design means: bore and stroke are both equal to 54.2mm). Even in racing 2-strokes the rule is: square design.

A 125cc 4-stroke having the same bore to stroke ratio with the Panigale 1299, has 67.2mm bore and 35.2mm stroke.

A basic limitation for both engines is the mean piston speed of the piston.

25m/sec mean piston speed is the typical limit for both of them.

This means a rev limit of 13,800 rpm for the square 125cc 2-stroke, and a rev limit of 21,300rpm for the oversquare 125cc 4-stroke.

And how this translates into power?

The power equals to the torque times the revs.

A 2-stroke has one combustion per cylinder per crankshaft rotation, while the 4-stroke has one combustion per cylinder per two crankshaft rotations.

If the torque of the 2-stroke 125cc were double than the torque of the 4-stroke, the lower revving 2-stroke would make only 30% more power than the 4-stroke (2*13,800/21,300=1.3) at the selected rev limit (25m/sec mean piston speed).

However the torque of the 2-stroke is less than two times the torque of a an equal capacity 4-stroke.

For instance:

the peak torque of the Panigale 1299 (1285cc) is 144.6Nm at 8.750rpm (11.4mKp / lit of displacement). At peak power (205PS at 10,500rpm, 21.3m/sec mean piston speed) the torque is only 5% lower than the peak torque,

while the peak torque of the Rotax E-TEC 800cc 2-stroke is, according Rotax, 123Nm (15.7mKp / lit of displacement), i.e. it is not 200% but only 145% of the specific torque of the 4-stroke Panigale.

Supposing the 125cc 2-stroke has the same specific torque with the Rotax 800 E-TEC 2-stroke, supposing also that the oversquare 4-stroke has the same specific torque with the Panigale 4-stroke, the calculation becomes:

1.3*145/200=0.94=94%,

which means some 6% fewer peak power from the 125cc 2-stroke than from the high revving 125cc 4-stroke.

There are 2-strokes making more specific torque than the Rotax 800 E-TEC.

However, with an even bigger than Panigale’s bore to stroke ratio (for instance 2, 2.25, 2.5) the four stroke can have even freer breathing and can rev at even higher revs without exceeding the 25m/sec mean piston speed limit.

For instance, a 125cc 4-stroke with 2.43 bore to stroke ratio (73mm bore, 30mm stroke) and with a PatRoVa rotary valve (no rev limit cylinder head, freer breathing, compact combustion chamber) could run at 25,000rpm (25m/sec mean piston speed). If it makes the same specific torque with Panigale, it would make:

0.125*11.4*25*1.4 = 50PS.

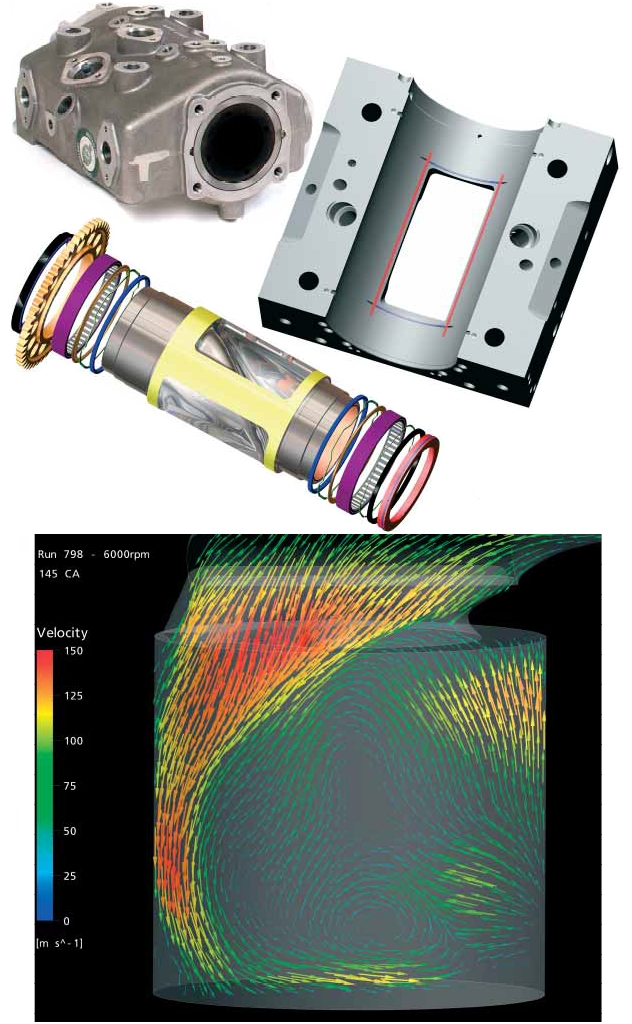

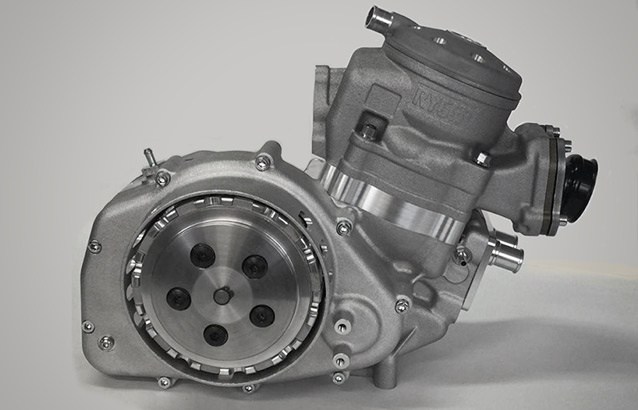

With two pistons sharing the same crankpin:

(here the bore to stroke ratio is as in the Panigale: only 1.91;

spot on the single piece casing, on the single piece crankshaft and on the single piece connecting rods; even so, the assembly is possible and easy)

a 250cc V-2 at 90 degrees 4-stroke with 100PS could be made.

If a higher mean piston speed is allowed (Ryger claims 17,500 rpm at peak power, which means (for 54mm stroke) 31,5 m/sec mean piston speed), the peak power of the 125cc oversquare 4-stroke increases proportionally (from 50PS to 31.5/25*50=63PS).

Thoughts?

Objections?

Thanks

Manolis Pattakos