Ferrari SF15-T

Active: 01-02-2015 - 2015

Team: Scuderia Ferrari SpA

Team: James Allison (TD), Simone Resta (CD), Corrado Lanzone (Head of production), Loic Bigois (AD), Dirk De Beer (HA), Mattia Binotto (HE), Bob Bell (Tech Advisor), Rory Byrne (Tech Advisor), Massimo Rivola (SD), Maurizio Arrivabene (TP), Sergio Marchionne (Chairman)

Drivers: Sebastian Vettel (5), Kimi Raikkonen (7), Esteban Gutierrez (Test)

The SF15-T is the sixty first car built by Ferrari specifically to take part in the Formula 1 World Championship. It was launched online on 30 January.

It is the second car made by Ferrari since the reintroduction of turbo engines in 2014. The first year of these new regulations was extremely challenging for the Scuderia and the lessons learned have been applied vigorously to the SF15-T to create a car that is in every respect a large step forwards with respect to the F14-T.

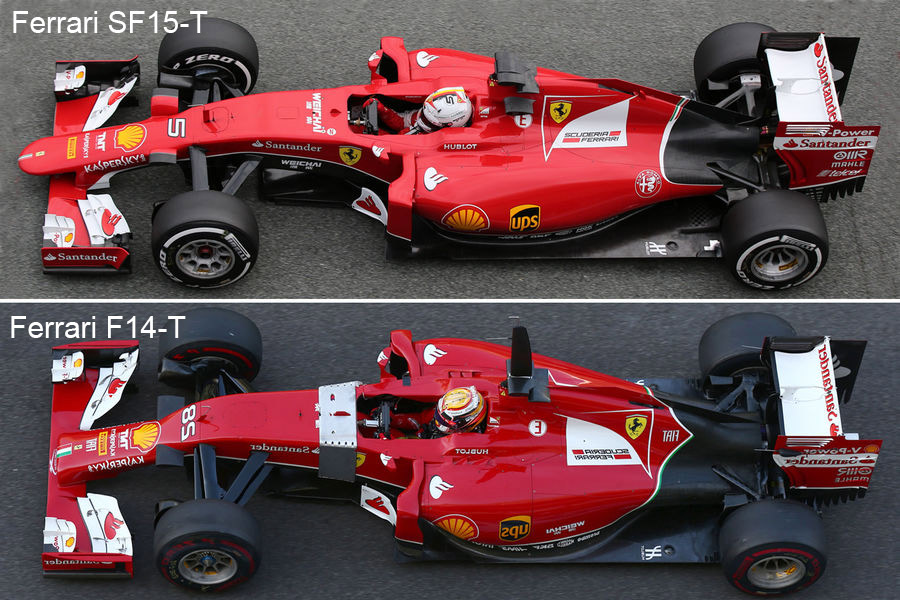

In line with the regulations, Ferrari have opted to design a low and long nose, extending over and ahead of the front wing. While Toro Rosso and McLaren initially opted for similar designs, they found shorter versions of their initial designs more efficient, resulting in redesigns, whereas Ferrari continued throughout the season with its long nose cone.

Apart from the obvious difference on the nose cone, the rest of the bodywork is a thorough development of the 2014 contender, featuring smaller sidepod cooling inlets, refined sidepod vanes and reshaped sidepods and engine cover make possible thanks to internal packaging changes.

The team also stated at the car's launch that "a much improved cooler matrix layout gained several tenths of a second per lap compared to the previous year". To allow for a more aerodynamic shape of the sidepods, the longer but narrower water coolers have been tilted down backward and outward and further optimised in a car update introduced at the Spanish GP. To ensure that the radiators kept working appropriately, even with their cooling air no longer hitting them straight on, Ferrari added small vanes on both surfaces to help spread cooling air evenly over the entire surface of the radiator. This feature is unique among all 2015 cars as most teams with similar radiator positions opted to create seperated ducting channels.

Ferrari worked hard at redesigning the rear wing family "to deliver stable performance in corners while producing a larger DRS effect on the straights", hoping to fix the lack of rear downforce that troubled the 2014 campaign. The front and rear brake ducts have been remodeled to produce more cooling of caliper and brake disk while generating more downforce than their 2014 counterparts. Both front and rear suspension kinematics have been overhauled to optimise tyre use.

Indeed, even though the company retained its front and rear pull rod suspension layouts, the front suspension in particular was greatly modified, partly for aerodynamic benifit, but mostly because the front bulkhead was lowered, making for less steep wishbones and creating a much lower roll centre for the front suspension than was the case for several years at Ferrari.

In the same effort, great care was taken to reduce aerodynamic drag, as Ferrari replicated Mercedes' 2014 idea of joining the lower wishbones into a single aerodynamic surface. The steering arm, a seperate element in 2014, was moved to align with the wishbones, invoking further drag reduction.

2014 was also the first year of the so called Brake-by-Wire (BBW); a system permitted by the rules as a way of allowing the maximum amount of electric power to be harvested under braking while maintaining an optimal brake balance. The latter proved to be a particular problem for most teams, including the Scuderia, but "the SF15-T is further optimized to produce a braking response that should allow the driver sensitive control while braking at the limit".

Power unit

The power deficit compared to Mercedes was Ferrari's worst enemy during 2014, and much of the team's focus therefore went into making improvements in that area. The team was adamant beforehand that it had made considerable progress, with images and on-track performances later showing they had indeed made a serious step.

"The power unit has been an area of extremely high effort to improve," James Allison said at the launch. "We had a number of issues with last year's engine and power unit. Early on in the season the power delivery was not particularly sophisticated and it was quite tough for the drivers to get the type of throttle response that they wanted. It was improved a lot during the season and we take that a step further for the SF15-T.

"A definite weakness of last year's car was that the amount of electrical energy that we were able to recover from the turbo was not really good enough for producing competitive power levels during the race - one of the reasons why Ferrari's qualifying performance was relatively strong compared to its race performance last year. We've tried to change the architecture of the engine to make it a better compromise between qualifying and racing performance.

It was also confirmed that, after Ferrari's struggles to get the fuel consumption of its 2014 power unit down to within the required limits, the Scuderia worked "an enormous amount" to improve all aspects of the combustion efficiency to exploit more energy from the amount of fuel that is available.

Modifications for 2015

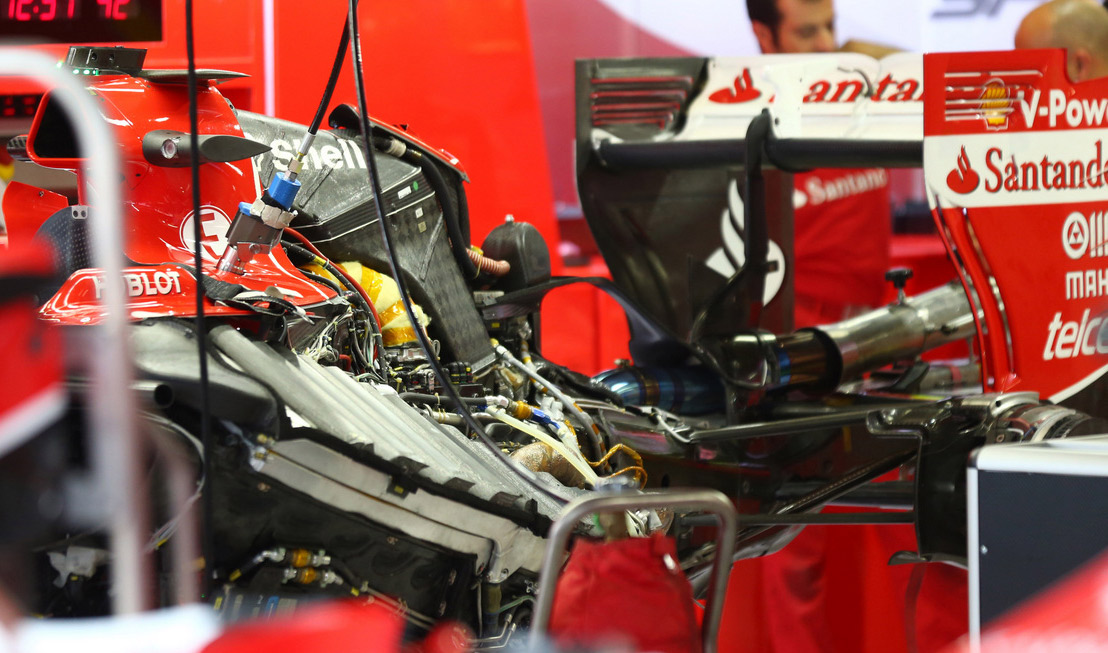

The packaging changes on Ferrari's power unit of 2015 are countless, the result of correcting the team's mistake of compromising engine power for compactness in 2014. One of the changes is the addition of a triangular cast aluminium stiffener on top of the cylinder heads, improving the stiffness of the car altogether. This was only possible by changing the exhaust pipes as well. Where the 3 pipes on each side curved up around the engine before merging, the 2015 layout has the equal-length pipes swirling into a merger pointing backwards, before turning upward into the turbo housing. The turbine itself continues to be twin-entry but is larger than in 2014 to be able to harvest more electrical energy from the turbine through the ERS-K.

Ferrari also reverted their solution to put the oil tank in the gearbox housing, behind the engine. The proximity to the turbo, along with its heat was probably created unwanted side effects. Hence for 2015, it was moved back to the front of the engine, a location similar to the other power units of 2015, and before that, on the V8 and V10 engines. The area that was freed up in the gearbox housing was put to good use as well. Making the casing higher and stiffer than before enabled the exhaust pipe to be channeled through the case, exiting on top ahead of the actual gearbox components.

The Ferrari power unit continued to use a water-to-air intercooler, located in between the two cylinder banks and their inlet manifolds. The engine also kept its fixed cylinder inlet manifolds, contrary to Mercedes, even though the regulations enabled engine builders to introduce variable inlet manifolds for their 2015 engines.

A lot of work had been done on improving combustion efficiency, an area in which Ferrari had particular issues in preparation for 2014. The team worked with Magnetti Marelli to improve the injectors and attain a better air to fuel mixture within the cylinders.

Roberto Dalla, motorsport director at Magneti Marelli, said: "We started on the project using the experience of our production car products, they were way ahead of us in terms of experience and technologies as we had not done a GDI system for motorsport. So we took onboard their experience, but not their product, as a basis. We decided to start over and build a brand new 500bar injector for F1 V6 engines."

As Ferrari is not the only PU manufacturer to use Magnetti Marelli's injectors, the company defined a flexible base design that could be adjusted, depending on the needs of the engine builder.

"There are different types of developments going on, the mechanical developments can take some time but the customisation of the nozzles and other related parts to change the fuel spray can be done very quickly, in perhaps two weeks from concept to delivery, and that’s really important for the engine builders," Dalla says.

"They are doing so many variations, in the last two years we have done maybe 70 or 80 different nose configurations and perhaps even more nozzles. Now we are passing the experience from the F1 project back to production cars."

On the back of Mercedes' strong partnership with Petronas, Ferrari similarly built a stronger relationship with Shell.

Luigi Fraboni, Ferrari’s head of engine operations said "Last year (in 2014) we were developing in parallel with Shell, but this year we have set targets to them in terms of performance and especially knock. They now know where we want to go and what we want to achieve with the engine and they have to get there. So each time we go to the dyno they will bring a number of candidate fuels to test to make sure we have the best for the races. I think now it is a very close relationship."

In-season upgrades

Still, Ferrari opted to save some of its limited power unit development tokens to introduce upgrades during the season. Of the available 32 tokens, Ferrari used 22 over the winter, allowing themselves to work throughout the season and gradually introduce further performance steps as soon as they were happy with the improvements.

Three of the tokens were used for upgrades at the Canadian Grand Prix, focused on control systems to exploit more power from the existing hardware while modifying combustion chamber components to further improve combustion efficiency. Some believe that upgrade was worth up to 15 bhp, with the team afterwards confirming that it had found on-track improvements in line with their expectations, and that GPS data analysis had shown that their power deficit to Mercedes had been reduced to almost nothing (Mercedes at the time also had 7 unused development tokens in their pocket).

At the team's home Grand Prix at Monza, Ferrari started using another new engine, including an upgrade that involved 3 further engine tokens. Its final two were spent on paper, as the team ran its upgraded engine on the dyno, but not on track to avoid penalties for using a 6th power unit.

Results

The continuous stream of improvements allowed Ferrari to keep Vettel's championship hopes alive for longer than expected, even though Lewis Hamilton eventually clinched the title with ease. The car was good for three wins, all in the hands of Vettel and 13 further podium finishes. Ferrari ended the season in a distant second place of the Constructors' Championship.

Specifications

Chassis: Carbon-fibre monocoque

Front suspension: Upper and lower wishbones, inboard springs and dampers actuated by pull-rods

Rear suspension: Upper and lower wishbones, inboard springs and dampers actuated by pull-rods

Dampers: ZF Sachs Race Engineering

Brakes: Brembo callipers and carbon fibre pads and discs

Transmission: Ferrari 8-speed quick-shift sequential carbon-cased gearbox, hydraulically activated. Longitudinally mounted

Clutch: Carbon fibre plates, by ZF Sachs

Differential: Servo controlled hydraulic limited-slip differential

Electronics: FIA standard ECU and FIA homologated electronic and electrical system (as provided by MES)

Tyres: Pirelli

Wheels: OZ, magnesium alloy

Dimensions

Height: 950 mm (minus T camera)

Track width: 1,460 mm (front); 1,416 mm (rear)

Weight: 702kg (FIA mininum; incl. driver and lubricants, tank empty)

Powertrain

Designation: Ferrari 059/4

Type: turbocharged, 90° 1.6l V6, assisted with kinetic and heat ERS

Valves: 24 (4 per cylinder)

Rev limit: 15,000rpm

Pressure charging: Single turbocharger, unlimited boost pressure (typical maximum 3.5 bar abs due to fuel flow limit)

Bore: 80mm

Stroke: 53mm

Crank height: 90mm

Exhaust: Single exhaust outlet, from turbine on car centre line

Injection: Direct fuel injection, limited to 500bar

Ignition: SKF spark plugs

Weight: Undisclosed (at least 145kg)

Total horsepower: Approximately 600hp (ICE) + 160hp (ERS)

Energy recovery system: Integrated Hybrid energy recovery via electrical Motor Generator Units

Energy Store: Lithium-Ion battery solution (up to 4MJ per lap), between 20 and 25 kg

Cooling system: Secan/Marston

Fuel and lubricants: Shell