Manolis wrote: “The lean mixture is not a limitation, any longer.”

Pinger replied: “Yes it is as it will incur greater pumping losses with its greater air requirement”

No.

The greater air requirement is not causing greater pumping losses.

Think of the Diesels.

Then think of the conventional 4-stroke spark ignition engines at idling, wherein a small quantity of air flowing through the engine (say 1/6 of the engine capacity per two crankshaft rotations) maximizes the pumping loss.

Quote from “your” link (end of last page):

The KHD Dz 700 two-stroke Diesel

Dr. Ing (Engineer) Adolf Schnürle, who was employed by Humboldt-Deutz, had earlier developed a new method for two-stroke cylinder porting.

Schnürle was put in charge of the new Humboldt-Deutz diesel engine project.

Preliminary tests were conducted in Cologne, Germany on small single-cylinder and two-cylinder engines.

In 1937, the Dz 700 was built. It was an eight-cylinder, two-stroke, air-cooled, diesel engine.

The engine had a 3.15 in (80 mm) bore and a 3.94 in (100 mm) stroke, giving a total displacement of 245 cu in (4.0 L).

The Dz 700 produced 158 hp (118 kW) at 2,800 rpm.

The Dz 700 had a diameter of around 38 in (1 m) and weighed only around 120 lb (55 kg).

A blower (weak supercharger) forced air through manifolds in between and then into the cylinders.

Utilizing Schnürle porting, the two intake ports were positioned slightly lower in the cylinder than the two exhaust ports, and all were covered and uncovered by the piston.

End of Quote.

As a Diesel, it is unthrottled (permanently WOT).

At partial loads the engine runs from lean to very lean to extremely lean (idling).

This means that at partial loads it passes through the engine several times more air than if it were running stoichiometric.

Here is the BSFC of a Diesel versus the BMEP versus the RPM, from Achates Power (2-stroke, Opposed Piston):

Quote from Achates Power: “The Achates Power engine has an extremely flat brake-specific fuel consumption (BSFC) map, illustrating that its high efficiency also extends to low loads.”

Take the point (1600rpm, 1.0bar BMEP).

While the air that passes per unit of fuel burnt is more than 10 times more than at the same revs and full load (at 14bar, 1600rpm), the BSFC is almsot the same.

If you take into account the significant mechanical friction of the engine (which absorbs a big part of the power provided at so light load), it is obvious that the pumping loss has very little to do with the quantity of the air passing through the engine.

Another example of what the pumping loss is (and is not), is the Toyota PRIUS engine that runs on Atkinson / Miller cycle and achieves top BTE.

At partial loads the intake valves stay open for a good part of the compression stroke to allow a significant portion of the entered air-fuel mixture to return beck to the intake manifold. Even at full load the 1/3, or so, of the entered mixture returns to the intake manifold; despite this “reciprocation” of air, the BTE is above 40%.

The KHD Dz 700 two-stroke radial Diesel of Adolf Schnürle provides its peak power at only 2,800rpm.

The modern Diesels for cars run at low revs, too (peak power at, or around, 3,500rpm is quite often).

The Diesel fuel injected into the compressed hot air needs time to prepare and get burned.

The part of the Diesel fuel that burns substantially after the TDC is burned at a substantially lower efficiency (because the actual expansion ratio is small).

The SkyActiv-X and the PatBam are, just like the conventional Diesel engines, compression ignition engines.

But they are also rid of the limitations of the Diesels.

The rev limit is way higher, the efficiency is higher (for the same compression ratio), the emissions are way lower etc.

Having said that,

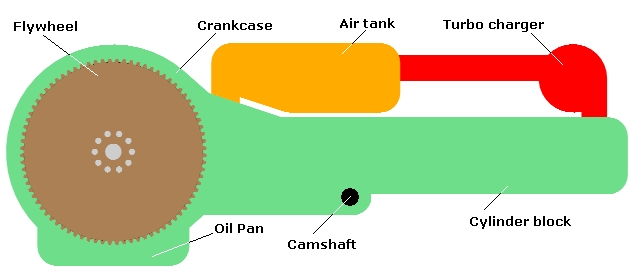

do take another look at the PatBam 2-strokes, say like the following Radial:

or like the following double OPRE Tilting PatBam for Portable Flyers:

and think of them as Diesel 2-strokes wherein the Diesel fuel (and the problems associated with the Diesel fuel, like: slow combustion extending at low expansion ratios, low maximum revs and so low specific power (bhp per lb of engine weight), NOx emissions, particulates emissions etc) is replaced by low octane gasoline that burns almost instantaneously (HCCI substantially constant volume combustion).

As the OPRE and PatOP ( at www.pattakon.com ) are highly unconventional 2-strokes (among others, at 6,000rpm they provide to the combustion of the Diesel fuel the time provided in the conventional engines at 4,500rpm; differently: at the same revs with the conventional Diesels, the combustion in the OPRE and PatOP is more than 30% more constant volume),

similarly the design of the PatBam 2-strokes is highly unconventional, and as such you can’t apply what you know from the conventional 2-strokes.

In an internal combustion engine the most important thing is the “combustion” itself.

Even a small improvement of the combustion is more important than a big improvement on any secondary process of the engine (say, like a kinematic mechanism enabling a lower frictional loss).

And the controllable HCCI is anything but a small improvement over the combustion: according the Mazda, their SkyActiv-X HCCI is 20% more fuel efficient than their current high-tech SkyActiv-G engines.

And I think Mazda knows better than anyone else the problems of the combustion, because they had in procuction for half a centrury the Wankel Rotary engine.

I recomend this excellent video:

Thanks

Manolis Pattakos