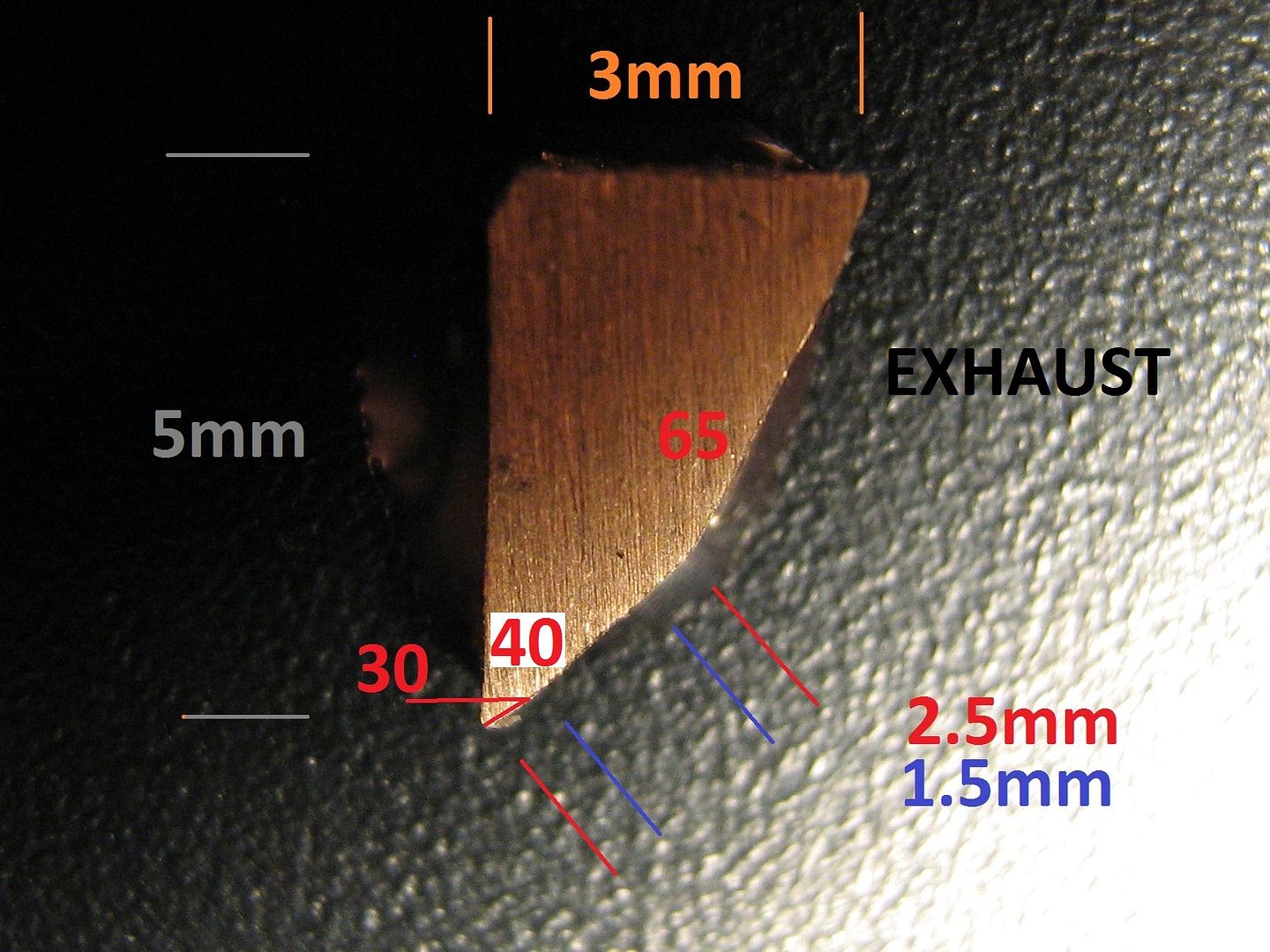

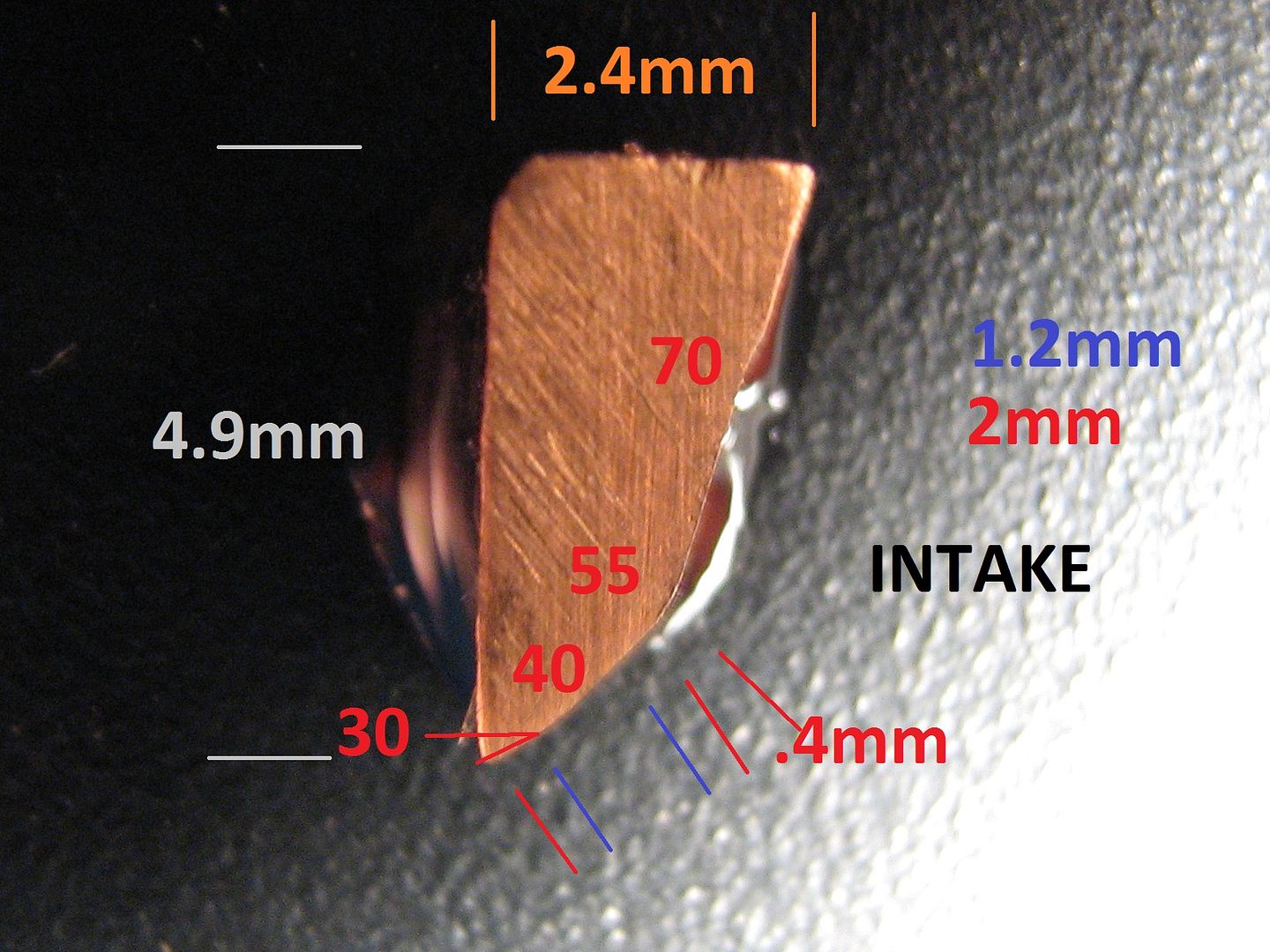

riff_raff wrote:Looks like the seats are BeCu. It's amazing that they got those thin section seats to stay put in the cylinder head, especially the 2.4mm wall seats used on the intake side. With such a thin radial wall section the amount of interference fit you can use when installing the seats is limited. Too much interference and the thin section seat will yield.

not really

call it BeCu orCuBe, it is a rather high strength material with an unusually low Elastic Modulus

so its yield strain is very high, it can be close to 10000 ppm

so has more scope in interference fitting than almost anything else ie it's very suitable for thin walls

and it has outstanding thermal conductivity of course

btw this is 2% Beryllium and very resilient (totally the opposite of high Be alloys that are banned as intolerably bad in fatigue)