Mudflap wrote: ↑25 Jun 2019, 23:00

ispano6 wrote: ↑25 Jun 2019, 22:43

PhillipM wrote: ↑25 Jun 2019, 20:48

That's nothing new it's something that's been done for decades, it's been looked at before for turbocharger turbines in motorsport before as well.

Mudflap wrote: ↑25 Jun 2019, 20:55

Not really needed for small radial turbines where you have sufficient support from the back disk.

Dove tailed axial turbinw blades are indeed a common application.

Never in the form of this type of application or pressures. So characteristic of Japanese technology (and attention to material detail and quality) and disappointed to hear the "over engineered" response to it.

Perhaps it is over-engineered to some other's reliability and durability standards, but not this Honda's! Good to see Honda pushing the envelope like they did during the Golden Era. They will need this durability and piece of mind to utilize this next stage of development.

Hold your horses - first off if you re-read the paragraph the single crystal turbine blades only refer to the aero engine - any association with the F1 turbo is pure speculation.

Secondly - just off the top of my head - the Audi le mans diesels ran hotter exhaust gases than current F1 engines and they got away with normal nickel alloys. I am sure there are many other examples.

As for the bolded text ... well, their reliability has not exactly been stellar in this era has it ?

Edit:

Another example - the Merc one hypercar which uses a F1 derived engine running very close to lambda 1 for emissions reasons and hence hotter than F1 has a "standard" mar247 turbine wheel.

Please, we're talking about what Honda has done, not what OTHERS have done in OTHER series. Sounds to me you're jealous of this high-tech! "So what, Audi did this, Toyota did that"...

It comprises two turbines, a smaller high-pressure component with single crystal blades producing lower fuel burn and a larger, low-pressure, counter-rotating turbine that boasts lower weight.

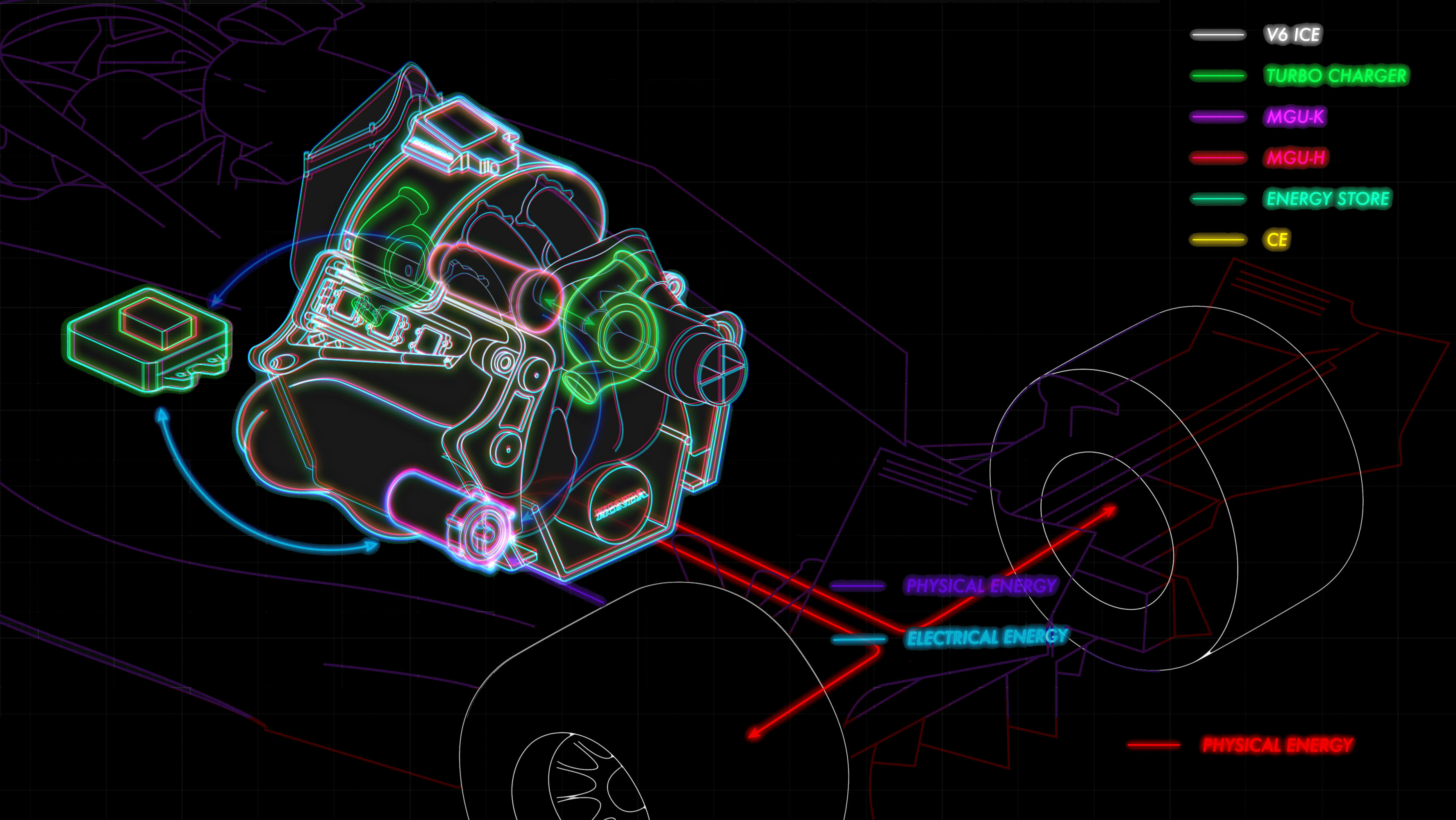

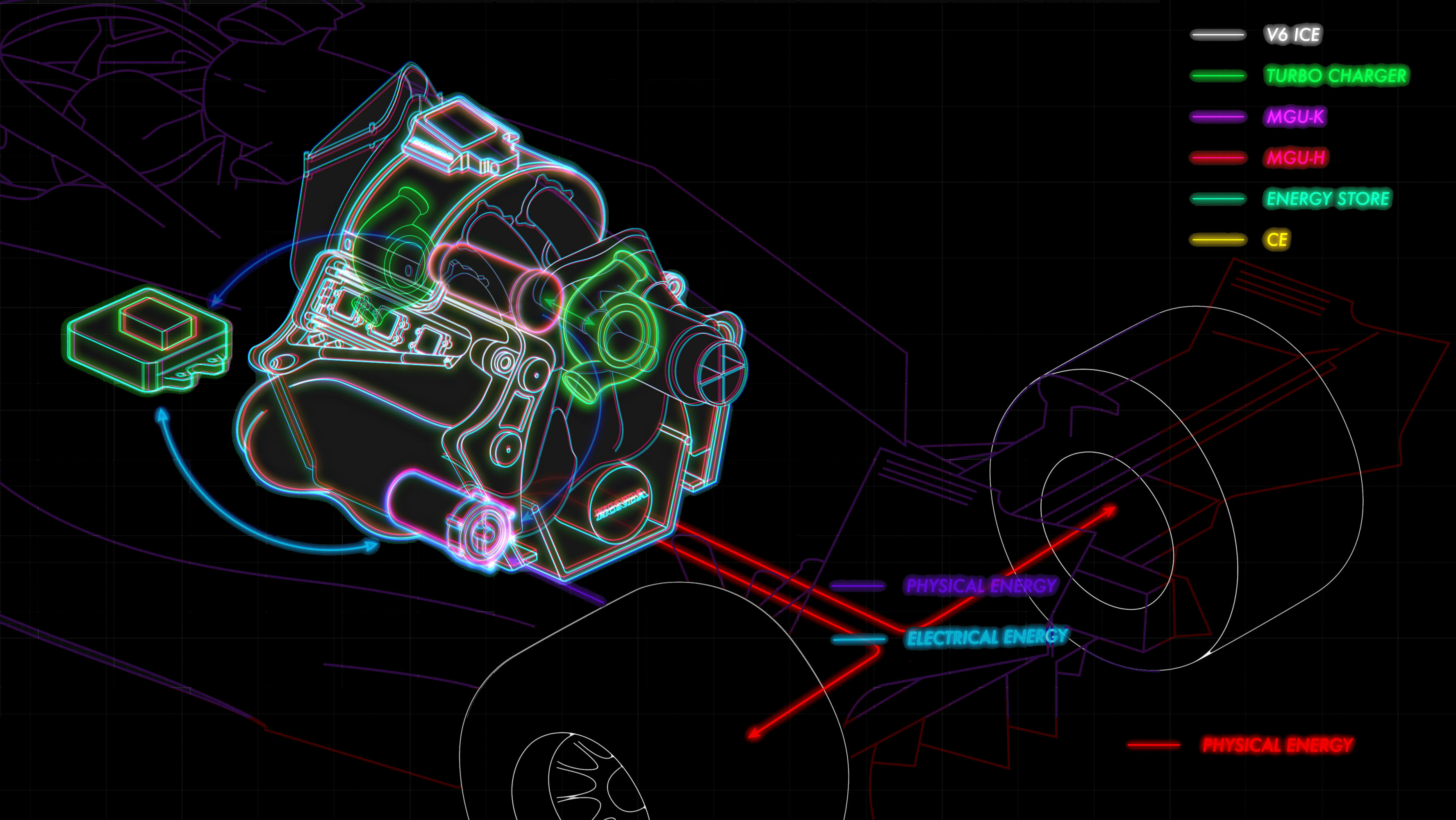

In Honda's diagram, there are two turbos. Which do you suppose gets hot gases and could use some durability insurance?

As for the bolded text ... well, their reliability has not exactly been stellar in this era has it ?

Bingo! So it's not pointless as you say it is. Afterall, it needs to be Alonso-proof.