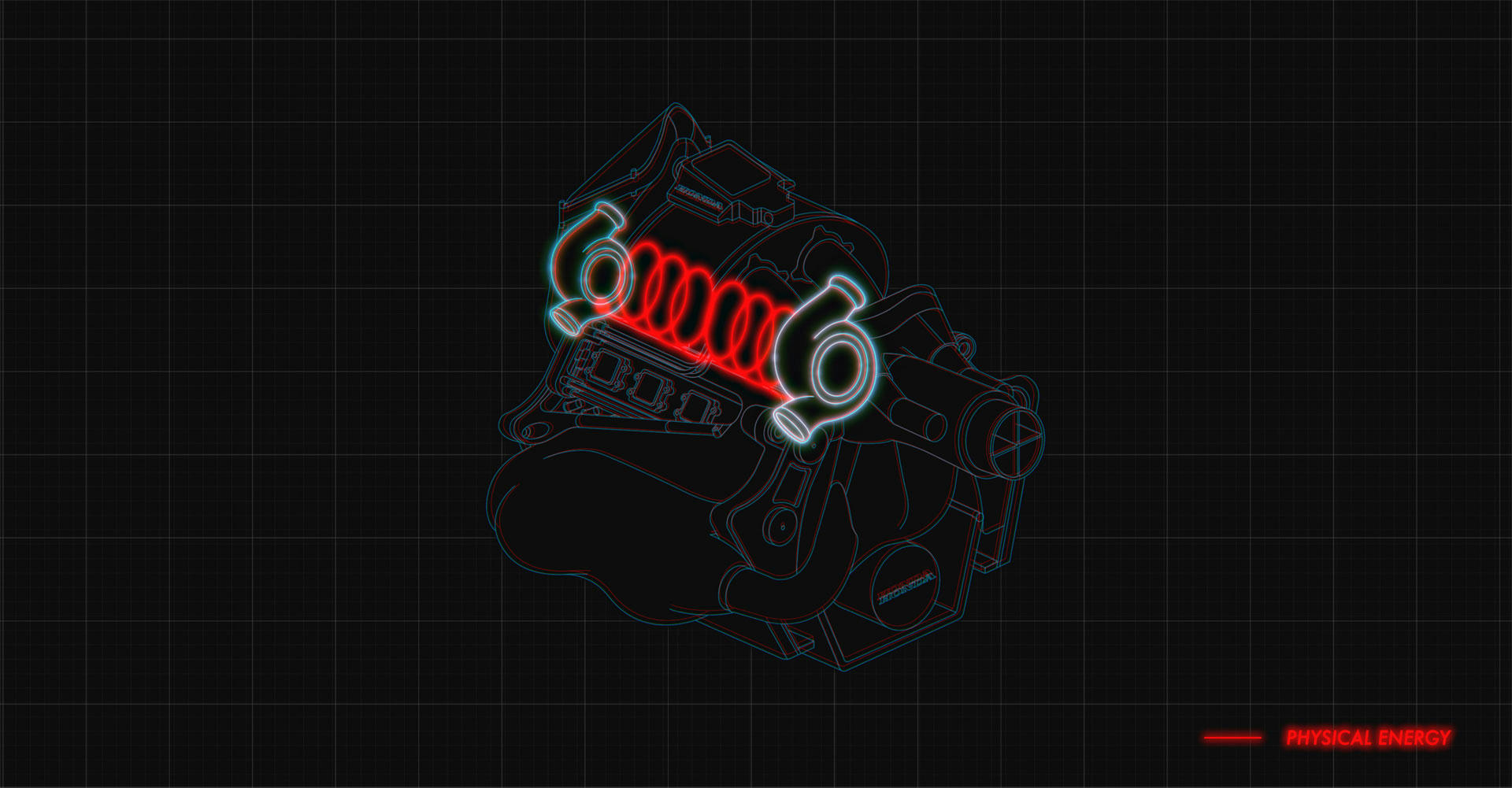

I'm inclined to think it's twin outlet for now, as for the right compressor pipe to be placed at that proximity to the compressor at that angle, looks like it has to come out of the compressor directly there, otherwise branch pipe must be bent very steeply there at almost impossible angle, or thrust through the oil tank which looks quite unlikely. Compared to the 2018 PU below, which had single compressor outlet on the left, seems it's quite obvious. Also the left outlet pipe looks slimmer than the main pipe of 2018's single outlet too.

btw Honda engineer said in japanese magazine at the end of last year that switching to separate pipe config for 2018 was to accommodate requirement from STR chassis as STR had separate intercooler on both sidepods whereas mclaren was single intercooler concept, meaning they didnt have much time to alter and design the compressor and piping for the separate intercooler config for 2018. So making it twin outlet for this year seems natural evolution.