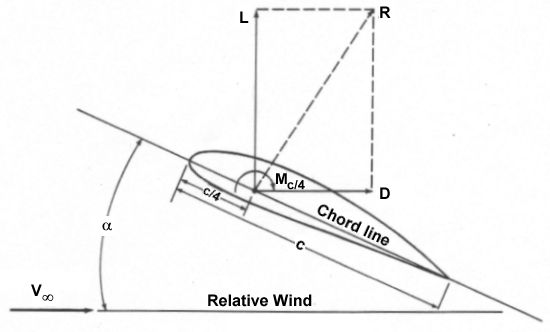

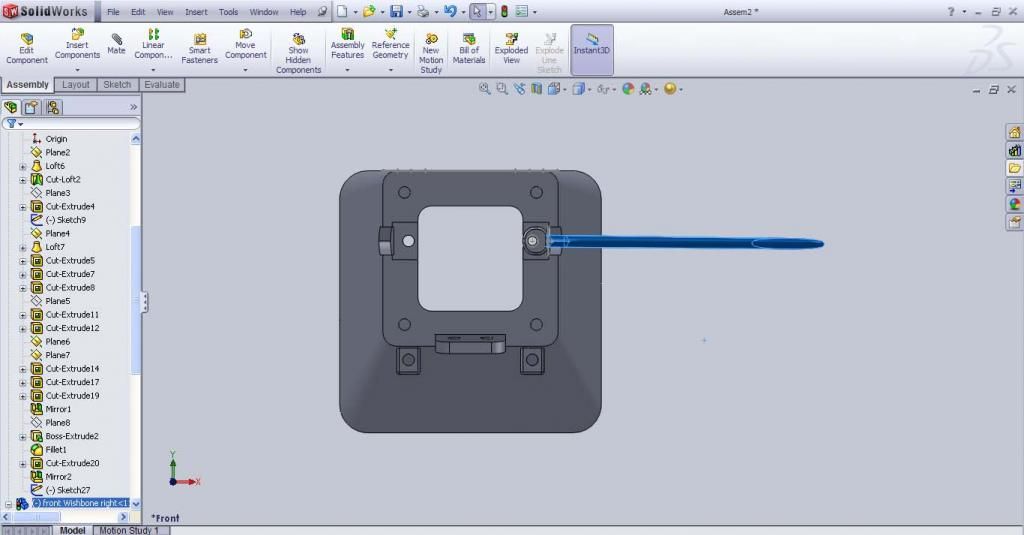

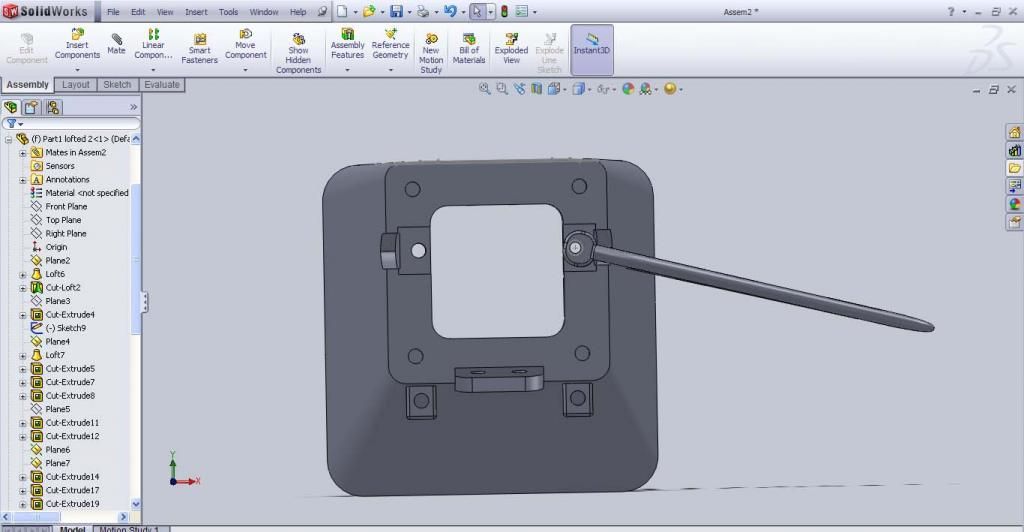

but how do they change the angle of these wishbones when needed, the angle with the reference plane on which sits the car if we're looking at the car from the front ?

- Login or Register

No account yet? Sign up

The suspension kinematics are defined in the early design phase and then usually stay for the whole season. The outboard points (at the upright) are easier to be adjusted. A change of the inboard points requires a new chassis or new gearbox. The setup is adjusted at the upright, simply by replacing shims which are placed under the brackets where the wishbones are attached to the upright. However these only affect how the wheel is positioned to the ground. So parameters like chamber, toe, track (with rim spacers). The kinematic itself can not be changed! This requires manufacturing of new parts with different geometries. Due to the F1 regulations the wishbone shape also needs some reworking when a kinematic point is modified otherwise they can become illegal.firasf1dream wrote:ok thanks so it's simply a flexible wishbone

but how do they change the angle of these wishbones when needed, the angle with the reference plane on which sits the car if we're looking at the car from the front ?

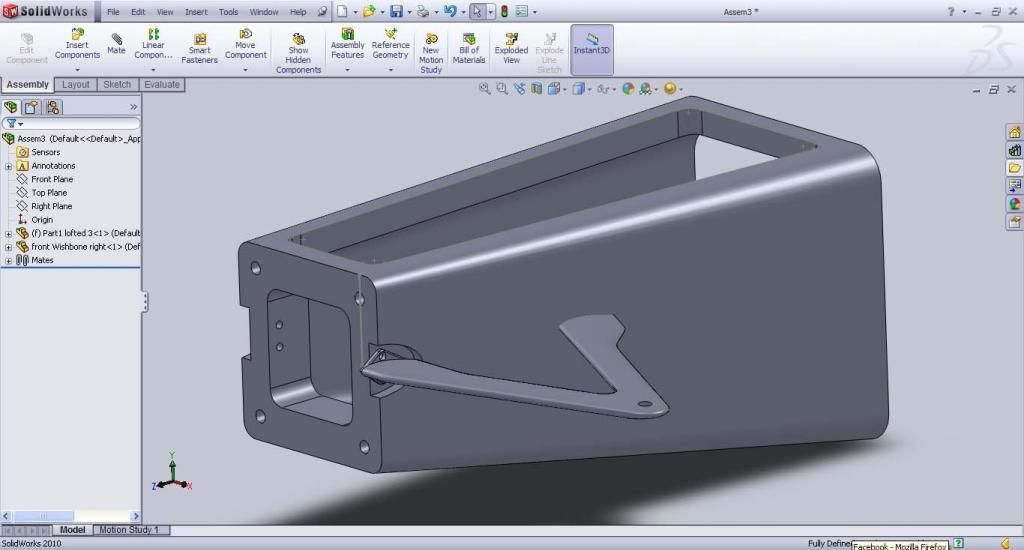

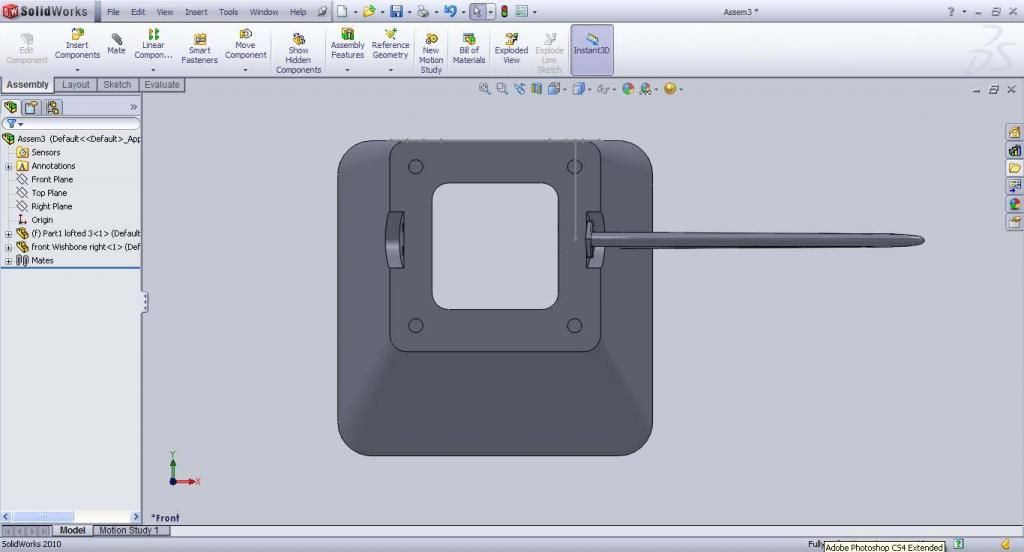

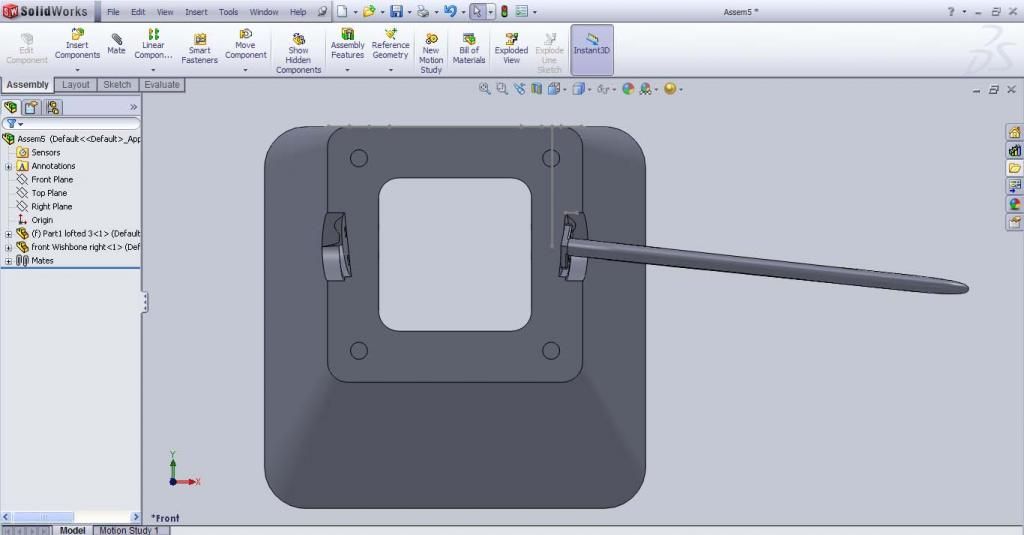

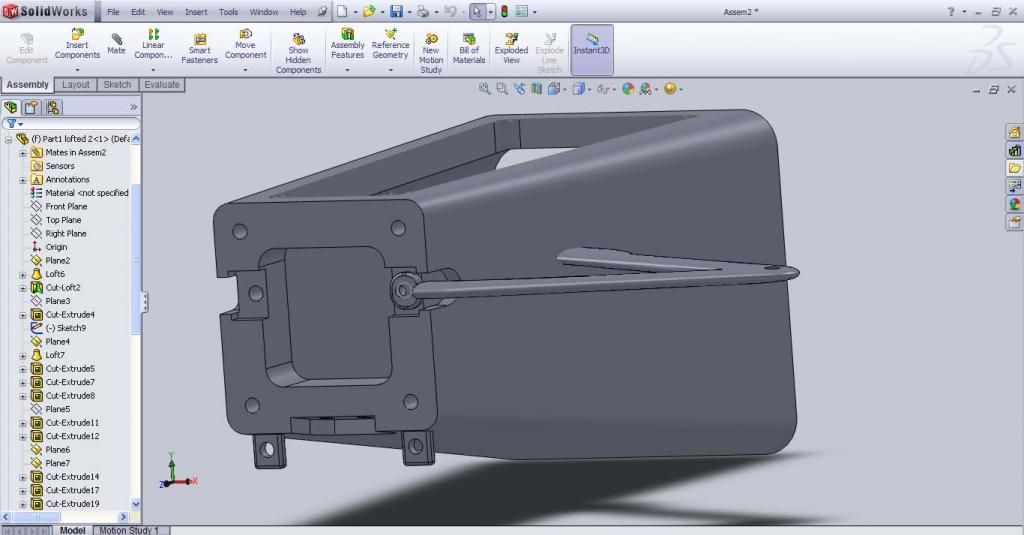

no need for the ball Joint ,mate . the Teams just put a bolt through tub and wishbone -end of Story. The Minute anular movement (at least at the front of the car )is taken up by the flexure design of the wishbone end- that´s what we told you all the time...firasf1dream wrote:ok great so i simply make a ball joint to make it a bit of flexibility between the wishbone and the tub and the cut that will be in the tub should be with a small angle to make the wishbone goes in angle to the reference plane when placed on ground ?

and about the screw that will go into the ball joint and attach the wishbone where it sould be, if not in the bulkead then it should be inside when open the cover will see it for the upper wishbone ?

and for the lower wishbone it goes from the bottom of the bulkhead up ?

you are the one designing it ,no?firasf1dream wrote:but i saw a car with ball joint

but ok way better without ball jointthanks a lot for the help

one more question i have : what is the angle of the slot or groove that the wishbone will go into in the tub ?