Hello Pinger

You write:

“Who wants an underpowered, overweight, running at the ragged edge of durability and smoothness engine?”

Who?

Hyundai, Delphi, Mercedes, GM, Nissan, Mazda etc, etc, etc.

Quote from

https://www.caranddriver.com/features/h ... gs-feature

Hyundai’s experimental engine—equipped with direct injection, variable valve timing, a turbo, a supercharger, and exhaust-gas recirculation—looks fairly normal on the outside. What’s weird are pistons with soup bowls cast into their crowns. With no spark plugs in the way, the injectors can squirt fuel into the exact center of each bowl. GDCI achieves auto ignition by heating intake air with carefully controlled amounts of exhaust gas followed by squeezing the dickens out of the mix with a 14.8:1 compression ratio. Injecting a small dose of gas just before top dead center, and the main fuel squirt just after that point, yields cylinder pressures that rise far more gently than those found in any diesel. This improves efficiency, since combustion pressure is working against a descending piston. Lean fuel-air mixtures, minimal heat lost through the cylinder walls, no throttling, and the large expansion ratio (the flip side of compression ratio) deliver fuel efficiency comparable to a diesel, according to Hyundai’s GDCI expert, the suitably named Nayan Engineer. (Mark Sellnau served as Delphi’s engineering manager on this project.) Best results derive from minimal swirl in the piston bowl. Fuel-injection pressures are in the gasoline-engine range, or only a fifth of what’s required in a diesel, yielding major savings in cost, lower parasitic losses, and quieter operation versus diesels. The supercharger delivers intake air at low speeds and loads when there’s insufficient exhaust energy to spin the turbo.”

End of Quote

In the above Quote, Hyundai and Delphi introduce their HCCI project with “great expectations”

Quote from

http://www.motortrend.com/news/whatever ... ci-engine/

“Homogeneous-Charge Compression Ignition engines have been a fascination of mine for some time, promising as they do, diesel-ish economy with gasoline-ish cost and emissions. Following a Hyundai powertrain technology briefing back in November 2013, I was pretty convinced that Hyundai’s HCCI program (which they dubbed Gasoline Direct Injection Compression Ignition, or GDCI) appeared likely to beat both the Mercedes-Benz DiesOtto concept and the GM HCCI engine to market.

Well, at this year’s

Hyundai powertrain-tech shindig, I got an update from powertrain honcho John Juriga as to just whatever happened to GDCI. He explained that

under compression-ignition operating conditions, the peak cylinder pressures were so great that the block and lower end (crank and bearings) needed to be strengthened to what is essentially diesel specifications, adding cost and mass.

All direct-injected gas engines have some issues with particulate emissions, and these were even worse with the GDCI engine, requiring a particulate trap not unlike what Mercedes is fitting to many forthcoming S-Class engines, which eroded the hoped-for emissions aftertreatment savings. The GDCI combustion process required considerable exhaust-gas recirculation, some of which was handled by retaining said gasses in the chamber using elaborate variable valve-timing mechanisms that added cost to the top of the engine. Achieving sufficient cylinder pressures at lower engine speeds demanded fitment of a supercharger in addition to the planned turbocharger, which added still more cost (and Juriga added that electric superchargers don’t represent much of a savings relative to mechanical ones).

This litany of cost overruns left a less expensive, lower pressure direct fuel injection system as about the only remaining cost savings relative to a diesel, so the program was deemed too risky and expensive. We suspect Mercedes and GM have come to the same conclusion, as all has gone pretty quiet on the HCCI front. But all hope is not entirely lost. Being able to vary the compression ratio is a real enabler for HCCI, and indeed the Infiniti folks suggested that a second-generation of their new VC-Turbo engine might employ HCCI to clear the next round of CAFE hurdles. Keep the faith!”

End of Quote

In the above Quote, it seems as the GDCI (HCCI) project of Hyundai / Delphi is now abandoned.

They are also mentioned the HCCI projects of

Mercedes, of GM and of Nissan Infinity.

Quote from

https://insidemazda.mazdausa.com/press- ... formation/

Mazda SkyActivX:

Range when HCCI could take place before the SKYACTIV-X:

SPCCI :

The expanded range of SPCCI (combustion ignition):

You also write:

“Major HCCI problem. The bottom end of the engine cannot withstand the very large nearly instantaneous rise in pressure when sufficient fuel to consume all the oxygen is supplied.Expect high NOx levels also.

That only leaves the possibility of running with mixtures so weak as to require a huge amount of excess air which is prohibitive in terms of 'air work' (the energy expended in filling the cylinder).“

The PatBam HCCI is different.

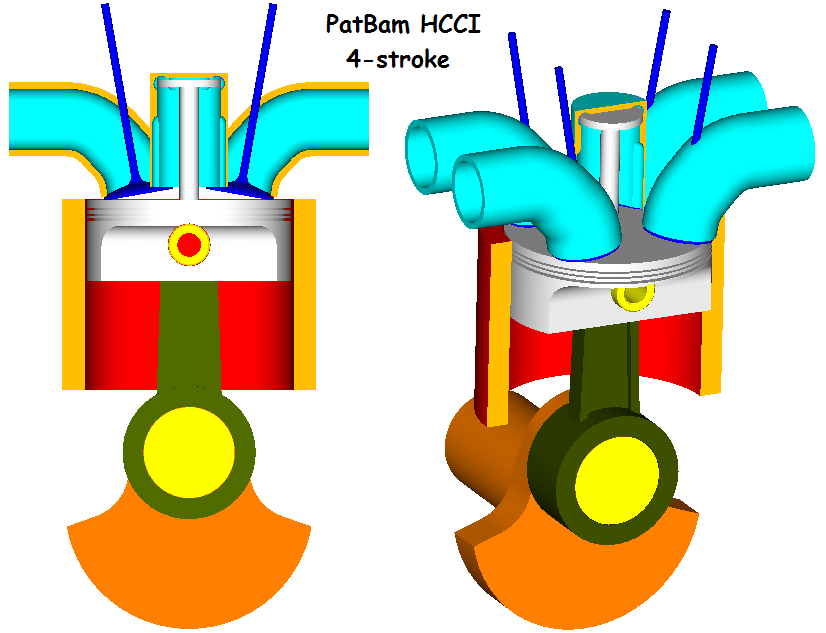

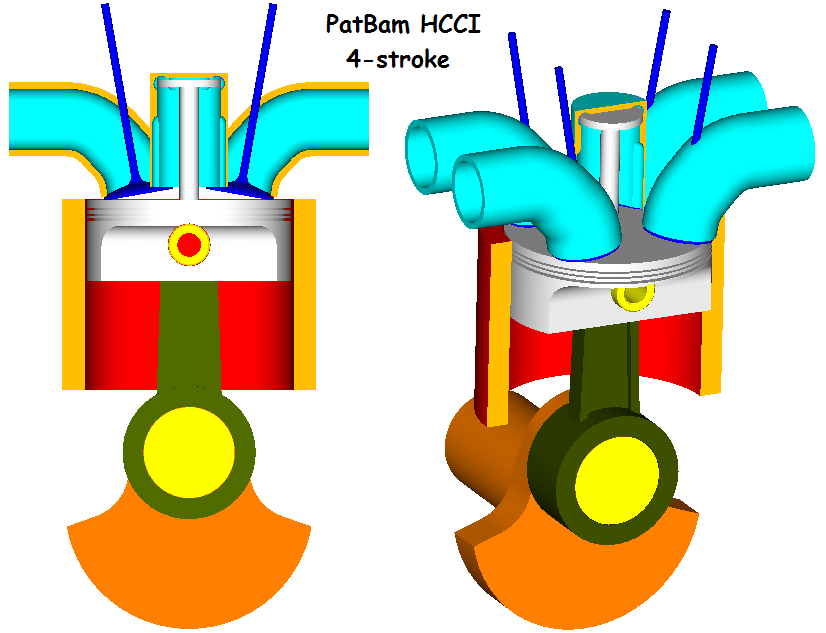

In the following PatBam HCCI design:

the diameter of the auxiliary piston is about 1/3 of the diameter of the main piston.

Similarly, in the following 4-stroke PatBam HCCI:

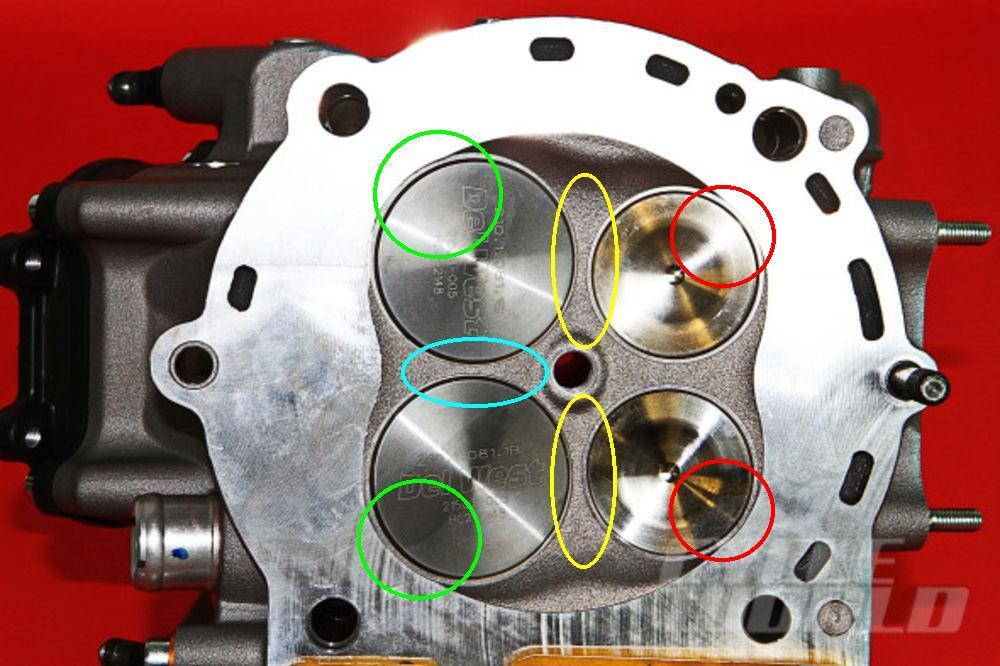

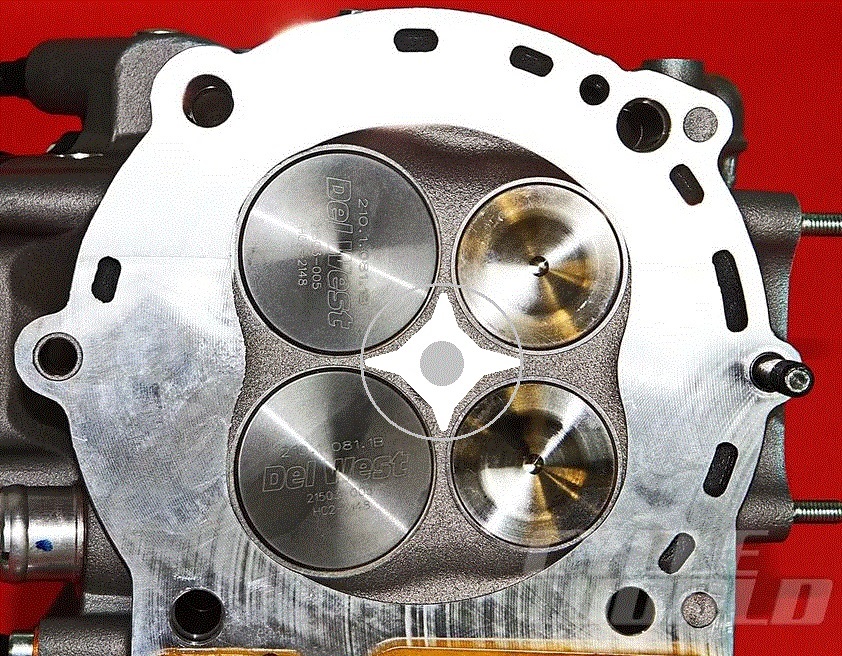

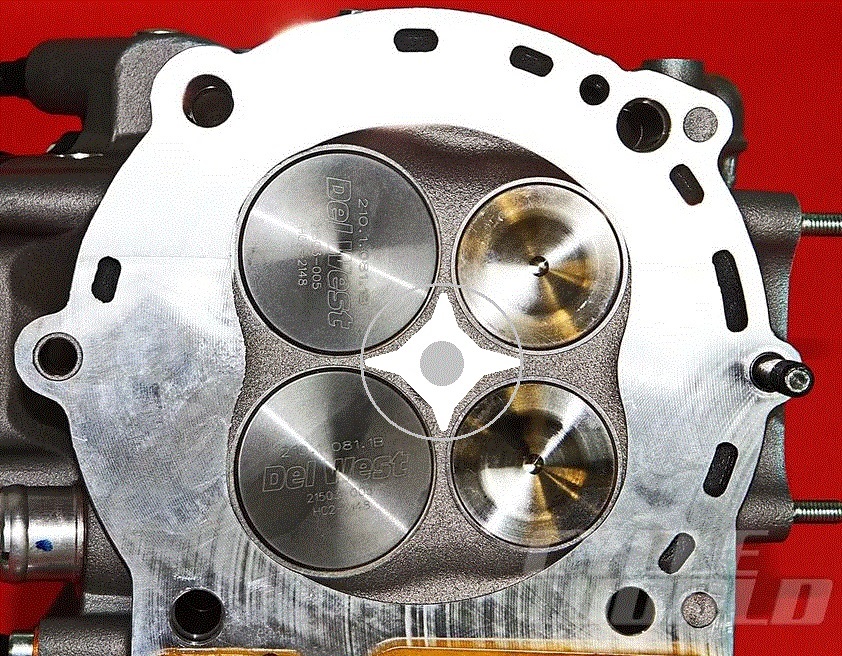

and from the "piston side", in case a Ducati Panigale is modified to PatBam:

the diameter of the auxiliary piston is about 1/3 of the diameter of the main piston.

This means that the surface of the auxiliary piston is about 3^2 times smaller than the surface of the main piston.

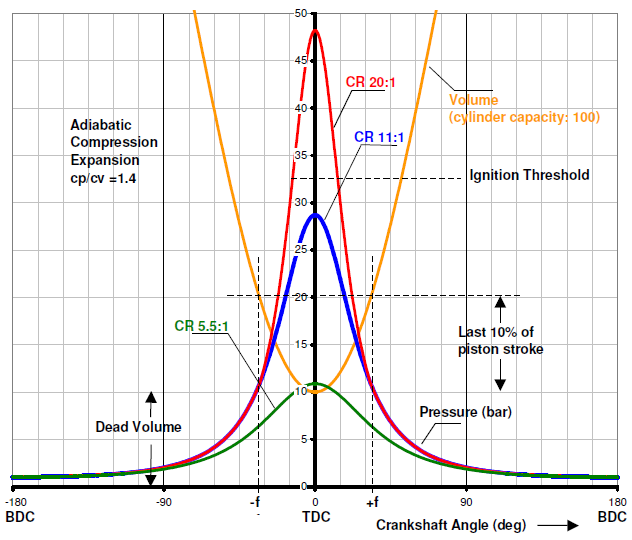

No matter how high the compression ratio in the auxiliary chamber is (say, it is 20:1 to cause the auto-ignition of the air fuel mixture at all conditions), the resulting loads on the kinematic mechanism are not heavy.

By the way: the HCCI combustion is not really instantaneous. It is some 5 – 6 times faster than the progressive burn in the Spark Ignition engines, but not instantaneous.

Keeping low the compression ratio in the main chamber (say, 11:1), the near “constant volume combustion” triggered by the entering from the auxiliary chamber burnt gas, cannot cause excessive loads on the kinematic mechanism.

As the Diesels, similarly the HCCI engines run better on lean mixtures; the leaner the better.

In the road tests of the Mazda SkyActivX (an almost HCCI engine) the consumption gets better if the engine runs at higher revs and lighter loads (instead of the conventional: lower revs, heavier loads).

It is not possible to consume all the oxygen in the cylinder of a Diesel engine. This is the way it works: from lean to extremely lean (at idling).

Yet the Diesels with the lean burn achieve higher BTE than the Spark Ignition engines.

And because the Diesels and the HCCI engines fit better with turbo-charging and super-charging, they are able to make lots of power.

So, the PatBam separates the HCCI combustion in two chambers, achieving a simple, yet strong control.

The high pressures in the auxiliary chamber cannot create extreme loads.

Neither the near “constant volume combustion” in the main chamber, which runs at low compression ratio, can create extreme loads on the kinematic mechanism.

With a 11:1 compression ratio in the main chamber, a BTE similar to that of a Diesel having 16:1 compression ratio (and running in near “constant pressure combustion) is reasonable.

As for the fuel, a low octane cheap gasoline is the best fuel for the PatBam.

The basic problem of the Diesel engines is their emissions (NOx and particulates).

The direct injection gasoline engines have similar problems with the Diesels.

The HCCI is a solution. But the HCCI needs strict control And the PatBam offer such strict control over the HCCI combustion.

Thanks

Manolis Pattakos