Sleeve-valves vs Opposed Pistons

Hello.

I was looking at this:

arrangement of Rolls-Royce Crecy 2-stroke as a solution for modern 2-strokes.

The sleeve valves of R-R Crecy move at double frequency than the sleeve valves of the Bristol Radials 4-strokes:

While the angular oscillation of the Bristol sleeve valves about their cylinder axes offers a significant functional advantage (maximization of the valve-time-area), this is not the case for the Crecy 2-strokes sleeve valves wherein the angular oscillation just increases the inertia loads and the friction.

In both cases it is required a strange connection between the sleeve valve and its actuator.

In both cases (R-R Crecy and Bristol sleeve) the sleeve valve is supported asymmetrically causing flexing and increasing the friction.

While the sealing of the combustion chamber of the Bristol sleeve valve engine is based on normal rings on the moving piston and on the stationary “piston”, in the Crecy R-R design the sealing of the top side of the combustion chamber is based on the tight fit of the sleeve valve top-end with the cylinder.

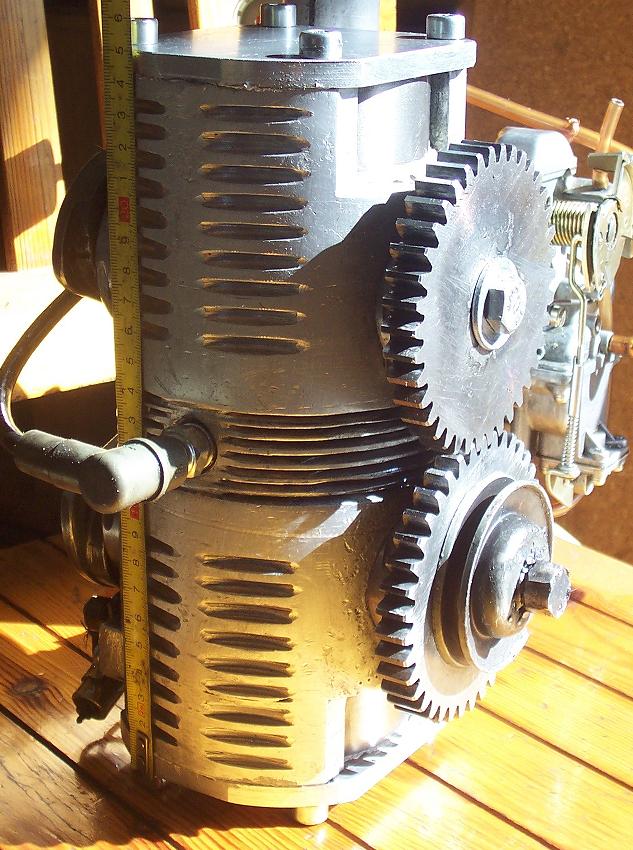

A better solution seems this:

It is from a prototype sleeve valve two-stroke engine made by Uniflow (F1 Technical Forum).

As compared to Crecy sleeve valve, it is symmetrically supported by a pair of auxiliary side-connecting rods on two slim crankpins of small eccentricity, avoiding the angular oscillation about the cylinder axis.

A common problem with the R-R Crecy is the scavenging efficiency of the top part of the combustion chamber.

Even in the giant Marine two strokes (wherein the stroke is several times bigger than the bore) a core of residual hot gas remains along / around the axis of the cylinder (in this case the exhaust is at the opposite end of the cylinder and not in the middle of the cylinder).

A common problem is also the need for long stroke to bore ratios to put the transfer and exhaust ports away from each other (to avoid short circuit). The small distance of the transfer port from the top of the above sleeve valve shows the problem.

A better solution seems this design:

At

http://www.pattakon.com/Sleeve/Sleeve3.gif amd

http://www.pattakon.com/Sleeve/Sleeve3_STE.gif are the above animations at full size.

For windows users the "exe" program at

http://www.pattakon.com/Sleeve/Sleeve2.exe may be interesting.

(the second animation can be seen stereoscopically according the instructions at

http://www.pattakon.com/pattakonStereoscopy.htm )

Besides the simple actuation of the sleeve valve (Uniflow), it also offers the sealing quality of the Bristol sleeve valve design wherein a stationary piston at the top of the cylinder has piston rings sliding on the sleeve valve. No tight fit between the sleeve valve and the cylinder is required.

With the exhaust ports at the top of the cylinder, the scavenging is more efficient (fewer residual gas, lower cycle temperatures).

It seems a good solution.

But, as in the previous cases, it needs a long piston stroke.

A long piston stroke means heavier inertia loads, more friction, lower rev limit and less power.

A common disadvantage in all previous cases is the increase of the inertia loads and of the vibrations (the heavy sleeve valve reciprocates in synchronization with the piston; the first order inertia force of the reciprocating piston adds with the first order inertia force from the reciprocating sleeve valve). A single cylinder would vibrate a lot more than a conventional single cylinder 2-stroke (same piston, same connecting rod, same stroke, same rpm).

A better solution is to put in motion the immovable piston of the last arrangement.

This is what the Junkers-Doxford does:

Instead of using the side connecting rods for the sleeve valve, now the side connecting rods are used for the top piston.

The sleeve valve is eliminated together with the associated friction; the lubricant consumption reduces; the friction reduces (two pistons moving at half stroke).

The first order inertia forces are fully balanced.

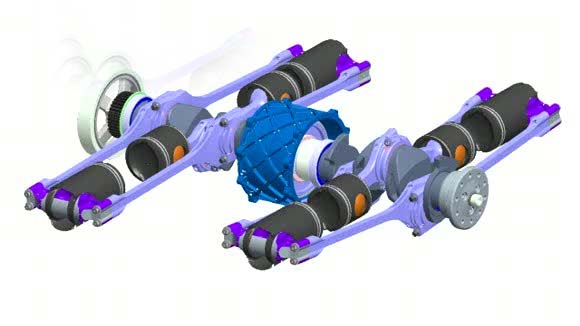

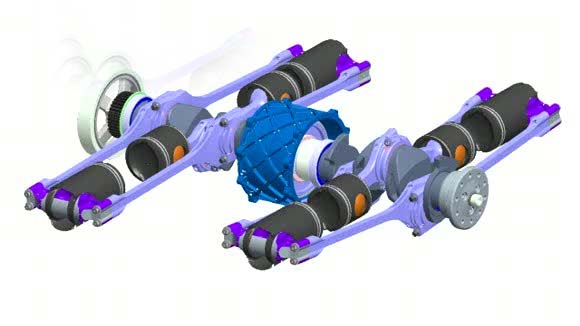

A better solution is the OPOC (Opposed Piston, Opposed Cylinder engine) of Ecomotors (Bill Gates is one of their famous investors): two Junkers-Dosford share the same crankshaft for the sake of full balance:

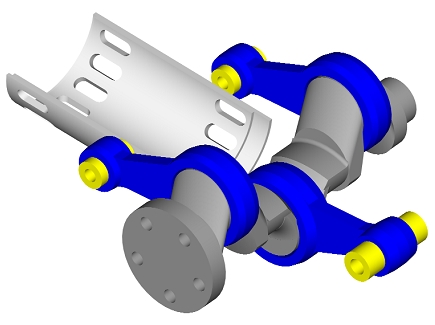

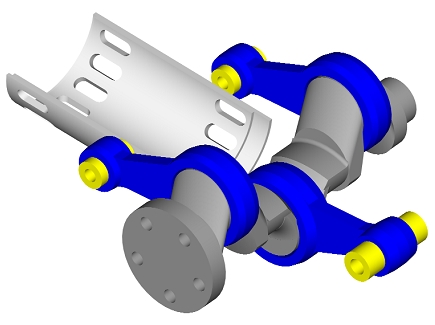

A better solution is the PatPOC engine:

(more at

http://www.pattakon.com/pattakonPatPOC.htm ; spot on the short crankshaft: the crankpins can be inside the cylinder footprint).

A better solution is also the PatOP engine:

(more at

http://www.pattakon.com/pattakonPatOP.htm )

Among others it reduces the overall height of the engine, it takes the thrust loads on surfaces rid of ports, it has “four-stroke-like” lubrication, it has built-in piston-type scavenging pump etc.

The “pulling rod” architecture of the PatOP increases substantially the piston dwell around the combustion dead center (think what this means for a high revving Diesel)

Worth to mention that the main bearings of the crankshaft of all abovementioned Opposed Piston engines can run unloaded (think why); theoretically you can hold by your hands the crankshaft at operation.

Thoughts?

Objections?

Thanks

Manolis Pattakos