What Greg says is correct but I'd add a couple of things.Per wrote:What does this delay actually imply? Does it mean lateral acceleration starts more gradually as the springs are being (de)compressed?

Would it be correct to say that the RC-CG lever has no direct impact on mid-corner performance (constant velocity and constant corner radius) but it does play a part in transient conditions (entry and exit)?

The fact that the body might have a lat acc delay doesn't necessarily mean that the car is responding slower. It just means that it is simultaneously rolling out of the curve and yawing in to the curve and as a result the body lat acc sensor sees a slightly lower lat ac in this transient phase. It may feel to the driver that the vehicle is slower to respond (because most drivers equate roll response to total vehicle response) but if you look at the yawrate instead of lat acc you may very well see a different story.

When I spoke about a delay in my previous response I was speaking about a delay in load transfer - not total response of the vehicle. Load transfer obviously does have an effect on handling and therefore a delay in load transfer could change handling behaviour but I think these would be very small "tactile" changes rather than something that globally changes the vehicle response in a big way. The fact that in 100 years of automobile design no-one, to my knowledge, has (publically at least) demonstrated the effects of roll centre movement on vehicle handling practically demonstrates that it's a small effect.

Another thing to keep in mind is that it's important not to get too caught up in the notion of the roll centre acting like a pin joint - unless you actually do have a beam axle with a watt's link. Independent suspensions work quite differently - things like symmetrical roll movements, absence of jacking, CG movements to the outer wheel due to roll angle in cornering are all incorrect behaviours which come about from the assumption that the body is literally pivoting about a point.

This simple point/rotation model is useful for getting 'ballpark' values for roll gradient, LLTD and their relative sensitivities to roll centre heights, roll rates etc. However the ball park gets quite big when you start comparing this model/way of thinking, to the results of a proper multibody calculation. The biggest inaccuracy is the fact that by assuming the body rolls about a point means you are simplifying a 2 degree of freedom axle to a single degree of freedom. And you pay for this in represented accuracy of the roll movement and wheel loads. The higher the lateral acceleration, the higher the inaccuracy.

What's missing in the point/rotation method is the jacking effects. In fact the most correct way of thinking about the roll centre effect is to completely forget about the notion of a roll centre and instead think of jacking effects coming from the left and right wheels. The roll centre effect is basically a measure of the jacking coming from the inside and outside wheels. Conceptually, the jacking force can be thought of as an extra force operating in parallel with the spring and damper:

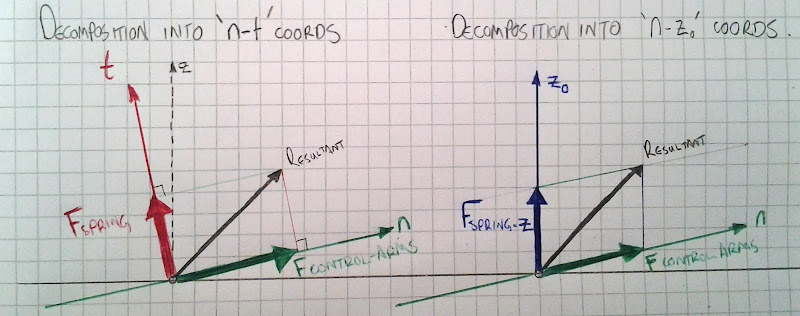

Jacking is a force acting on the body from the wheel which acts (usually) against the rolling effect of the load transfer. It's essentially anti-dive but applied laterally. The jacking force at each wheel is equal to the lateral wheel load multiplied by the 'n-line' slope. Here's an old image I made for another discussion but shows the n-line and how the cornering loads act along and across it:

Here the jacking forces are 'Fspring'.

From this its possible to understand that in cornering the outer wheel has more horizontal load than the inner one and therefore it's jacking force is usually greater. So you have a large upward jacking force from the outer wheel and a lower downward force from the inner wheel - both acting on the body. The sum of the two is a net upward force (total jacking force) which lifts the body during cornering. This is why most vehicles have assymetric roll (with less compression on the outer wheel compared to extension on the inner wheel). Essentially you have a roll angle and a vertical movement super imposed.

A more in depth analysis is made here by Erik Zapletal (username 'Z') on the FSAE forums which includes this nice image:

The relevant link: Jacking Force thread on fsae.com

This is a nice illustration of a RC which migrates at the speed of light to and from infinity which causes a lot of old skool suspension engineers choke on their coffee - but looking at the pure physics of the problem - this movement is absolutely inconsequential to the tyre loads and hence the handling behaviour.