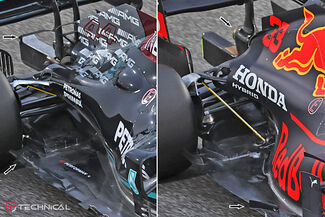

Engine cover design philosophy: Ferrari vs Mercedes

Where the Ferrari F1-75 and the Mercedes W13 were already vastly different beast when it came to sidepod design, their 2023 contenders are even more contrasting.

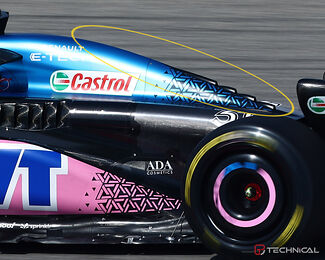

Taking a quick look at the way they have approached the airbox and engine cover design it is clear that Ferrari's SF-23 has a very slim, triangular airbox that rapidly converges in the flat, black vertical panel required to meet the minimum surface regulations. The bodywork at the back is so closely packaged that you can vi... Read more