That's good to hear! I will try my best to keep this clear and concise, but as an engineer that isn't always easy.

First, for the performance of the car you want the absolute lightest vehicle that is the most aerodynamically efficient. The primary forces that will slow your vehicle are Drag and Rolling resistance. The other slowing force will be contact with the guide wire or track if the car doesn't travel very straight (but this is most likely very small). So your key improvement areas are drag and rolling resistance. Rolling resistance is basically the cars resistance to roll when a force is applied, or the tendency of a car to decelerate as it rolls from a given input force.

If you recall from an earlier post, drag force can be summarized by:

Drag=Cd*1/2pv^2*A

The force from Rolling resistance is summarized by:

F=(Cr)*N

Where:

Cr=the coefficient of rolling resistance (this can be measured if you have sensitive instruments)

N = Normal Force (this is simply the weight of the car on horizontal ground)

This is why Mertol correctly stated that minimizing weight will help a lot. Not only will it reduce the decelerative force from rolling resistance, it also reduces the overall inertia of the car allowing it to accelerate from the cartridge sooner and to a higher top speed.

Now to the fun part! You can use the 2 formulas to detail why your design is such, and how you used applied math/engineering to reach an optimized design. This will be especially important to the portfolio, presentation and judging portion of your project. So you should absolutely document this process and make any pretty charts you can.

To apply the formulas to your design, you will note that you want to minimize both drag and rolling resistance. The first way to reduce rolling resistance is to reduce weight as we already discussed. Document the weight you reduced from the first model so that it's clear this was a mathematical process.

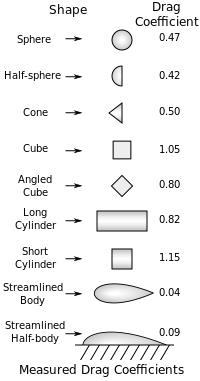

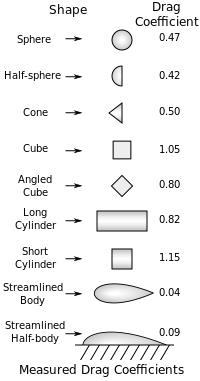

Next, you want to reduce drag forces. Again, we discussed that you can do this by reducing frontal area and the coefficient of drag. The following image is taken from a Wikipedia article and it details the different drag coefficients of various shapes. As you can see, if you went simply from a cylinder to a sphere, you cut your total drag almost in half. Again, document all of these findings. You will want to use CFD to ultimately determine the coefficient of drag, but knowing the general shapes beforehand will help you get there sooner.

Secondly, you mentioned that you wanted some positive lift to reduce the "weight". This will in fact reduce the normal force...which will drop the rolling resistance as well. BUT...by creating lift, you will create more drag. So what you want to do is what we call a trade off analysis or trade study in the engineering world. This means you look at the drag force that is added to produce the lift, then you look at the reduction in rolling resistance from this lift. If the added drag is MORE than the benefit from reduced rolling resistance, then you know that it's not worth it. But, if reducing your rolling resistance is in fact worth the additional drag, then you should create the positive lift.

My advice to your car is to look at various streamlined bodies to try and create a shape with a low Cd, then to reduce as much frontal area as possible while keeping a low Cd. The back of your car is flat, try to tape it towards the end of the cylinder if rules permit. The front wing is pretty blocky and will have a high Cd as well. Try to streamline any component and blend them well together.

Also, surface roughness matters as well, so try to smooth the surface of your 3D print as much as possible to keep the air flow laminar and attached. Typically, 3D prints have some ridges that can be cleaned up.

Again...Document EVERY process in a clear and concise manner for judging.

[/img]

[/img]