Hi folks!

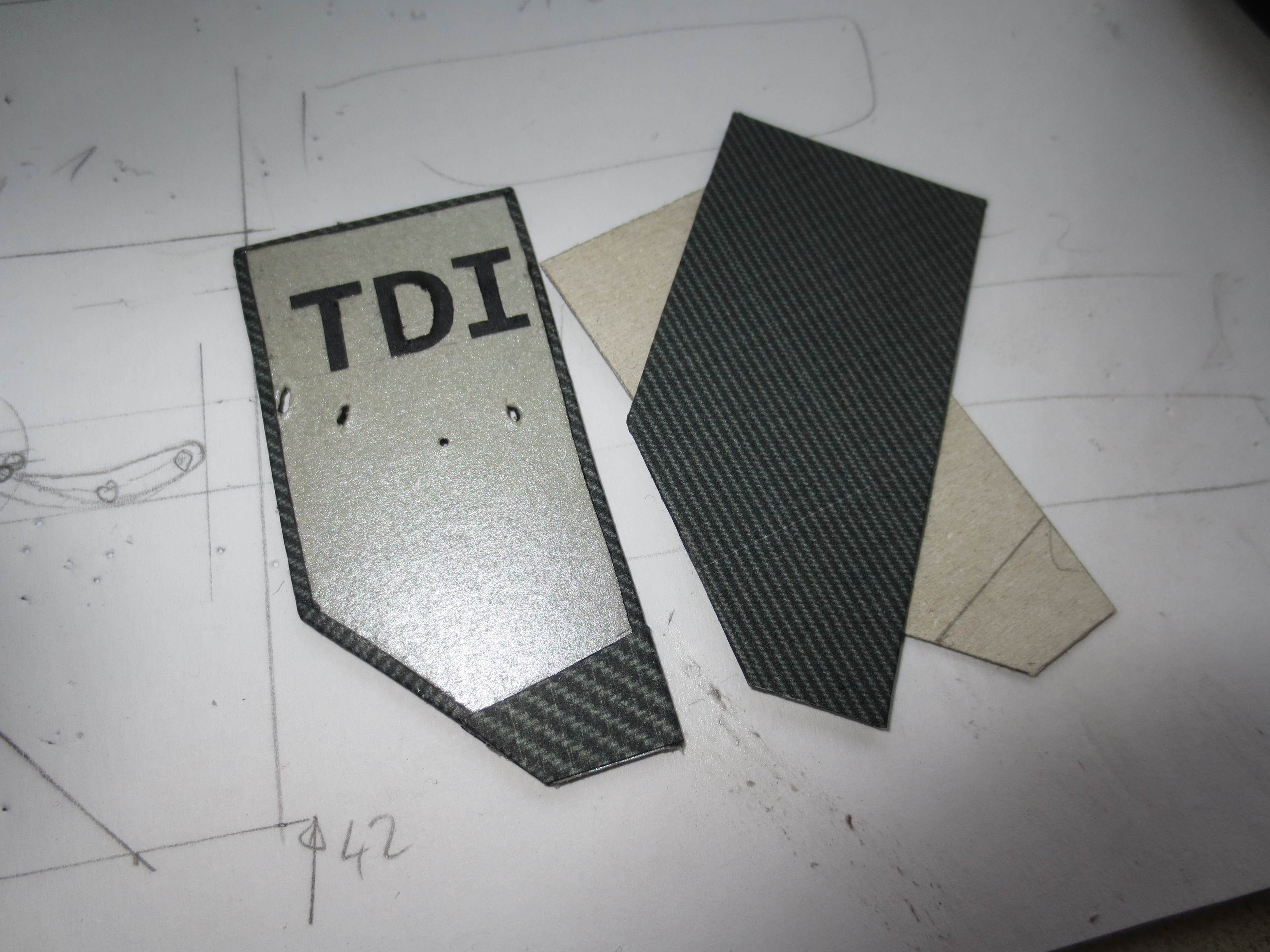

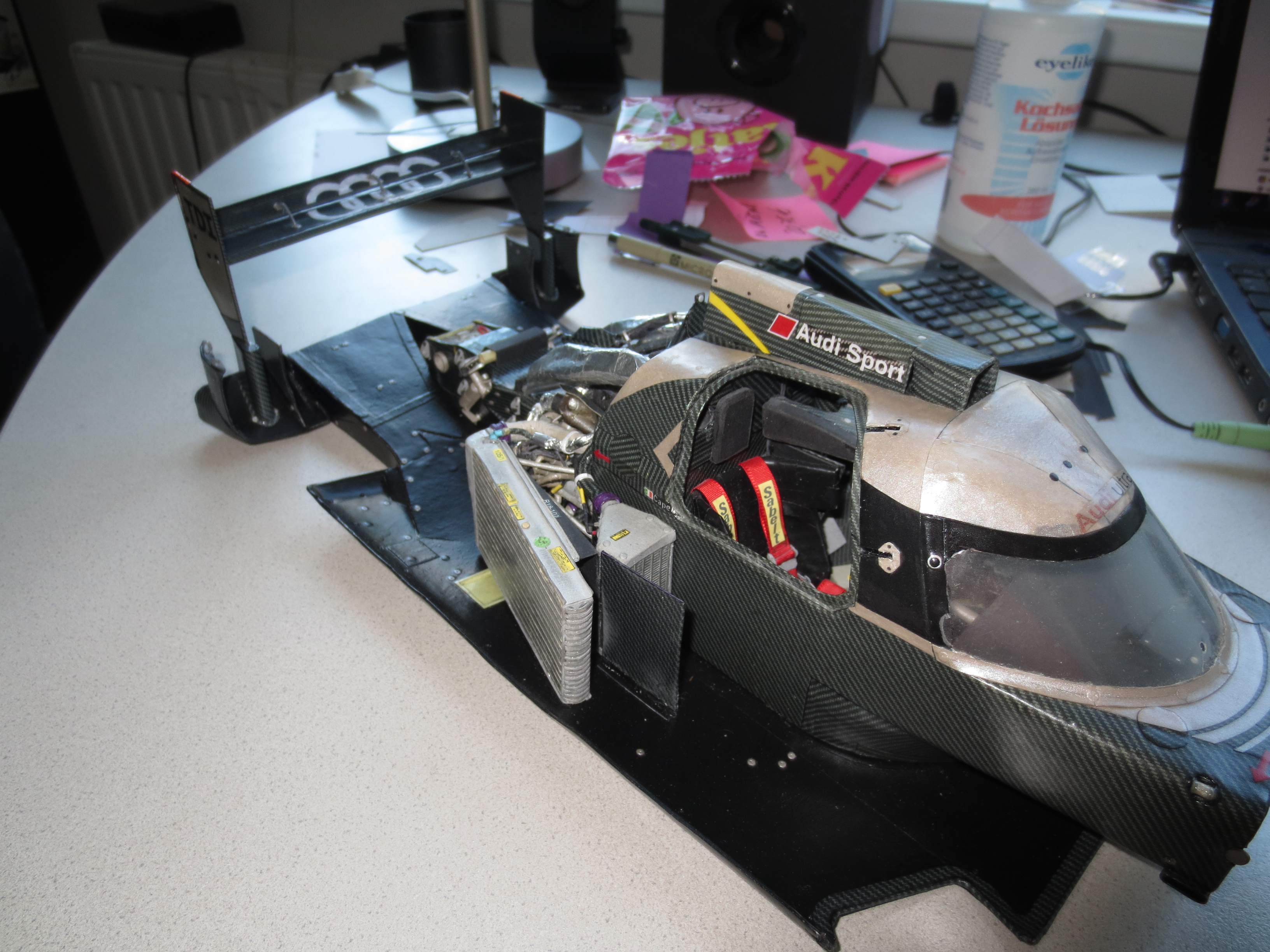

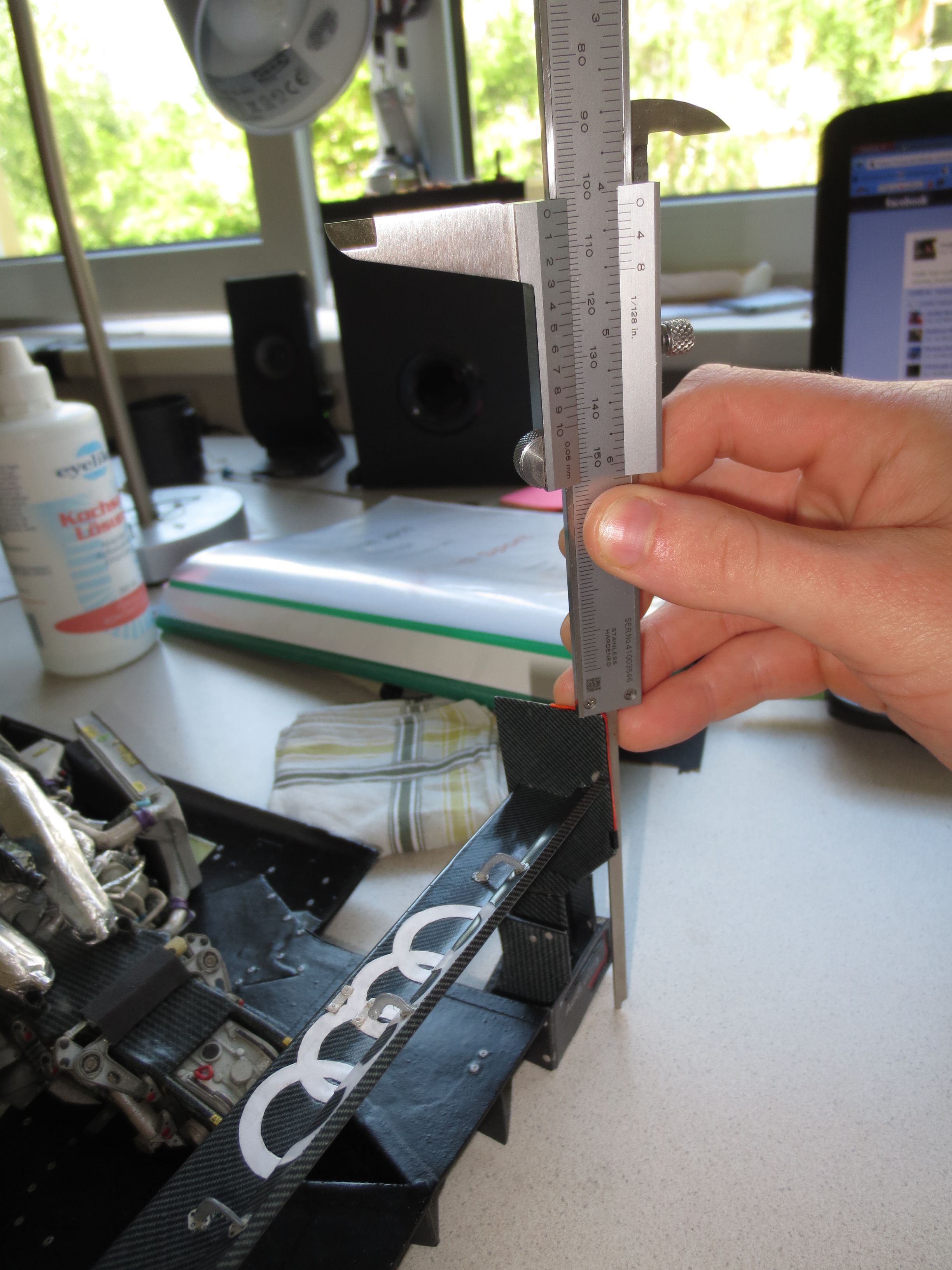

For given reasons, namely finishing the Audi’s rear wing, I’ll do a little comparison between modern (2011) F1 (Red Bull RB7) and LM (Audi R18 TDI) rear wings.

In generally you can say, that F1 is much more (very much more) regulated than Le Mans cars. Only if we take a look on the tech regulations, you can see the enormous difference. On the one hand the F1 tech regs with 74 pages and on the other hand the LM tech regs with 52 pages each with English and French text. So in reality we have the F1 regs with 74 pages and the LM regs with 26 pages!

Also the notation is quite different. In the F1 regs you won’t find the word rear wing or end plate. There you can interpret the

“bodywork behind the rear wheel centre line” (Article 3.10) or

“width behind the rear wheel centre line” (Article 3.5) against the LM regulations where you can literally read the regs for

“Rear wing” (Article 3.6.3) in point

“3.6 – Aerodynamic devices”.

saca

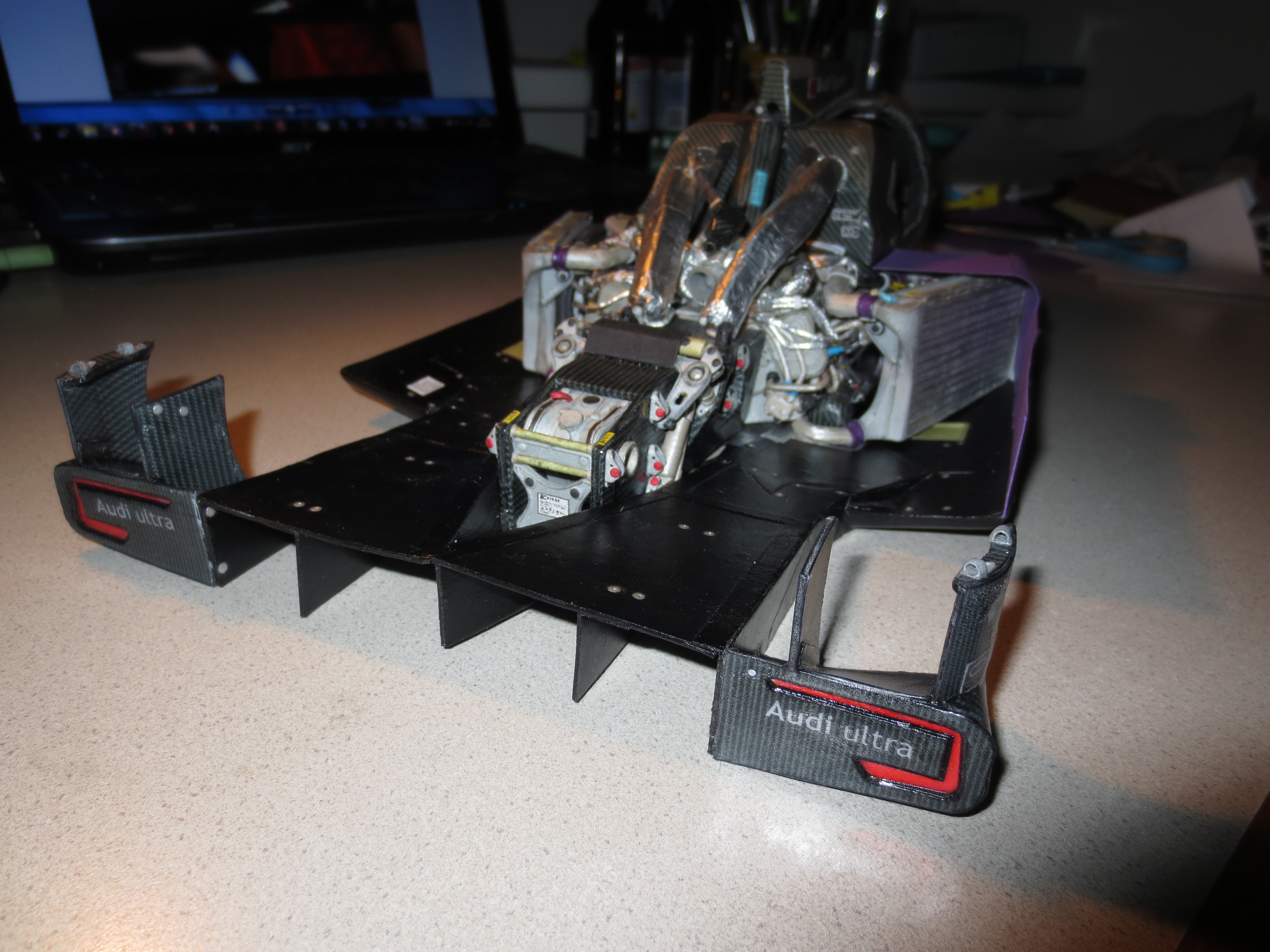

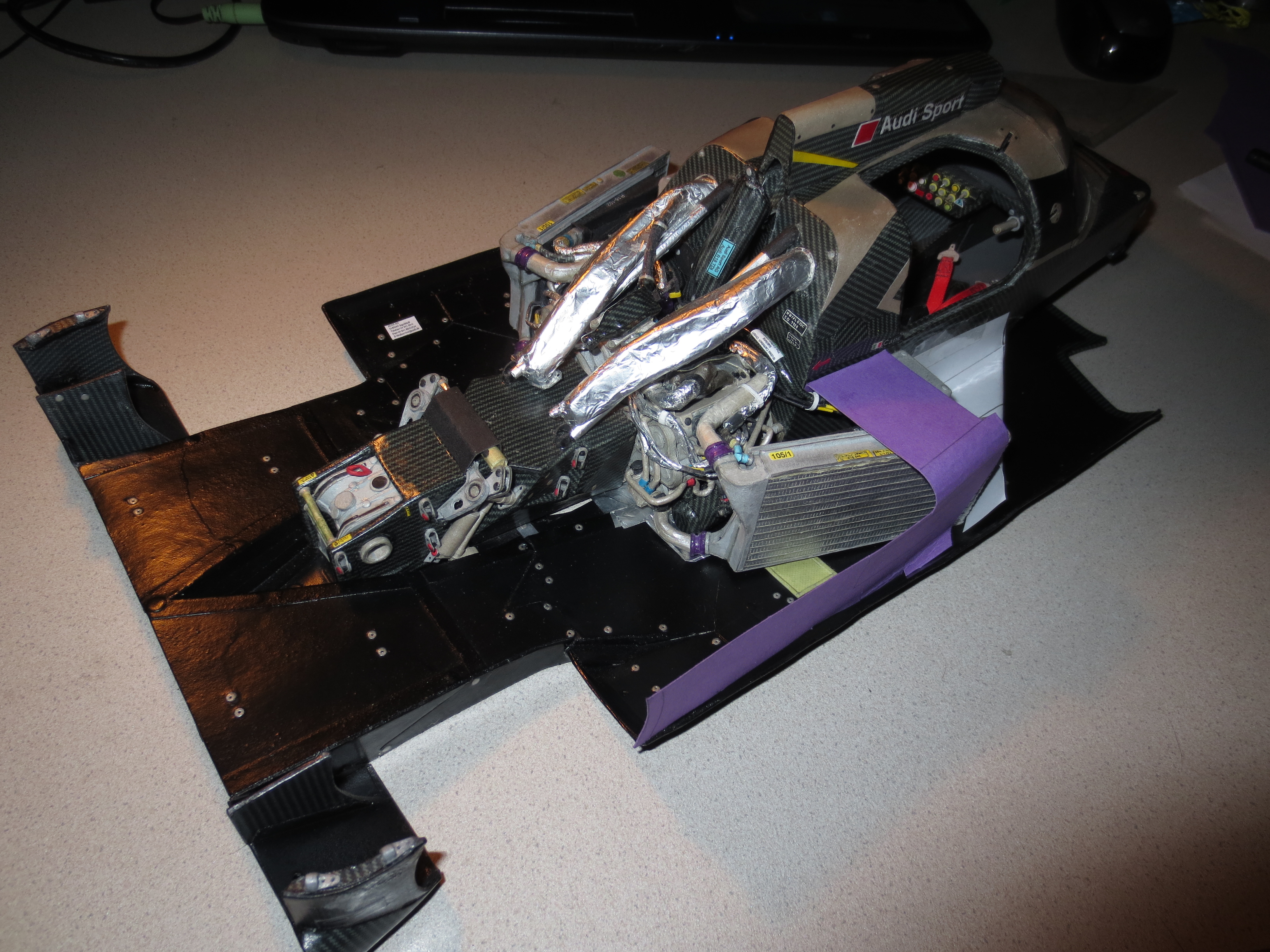

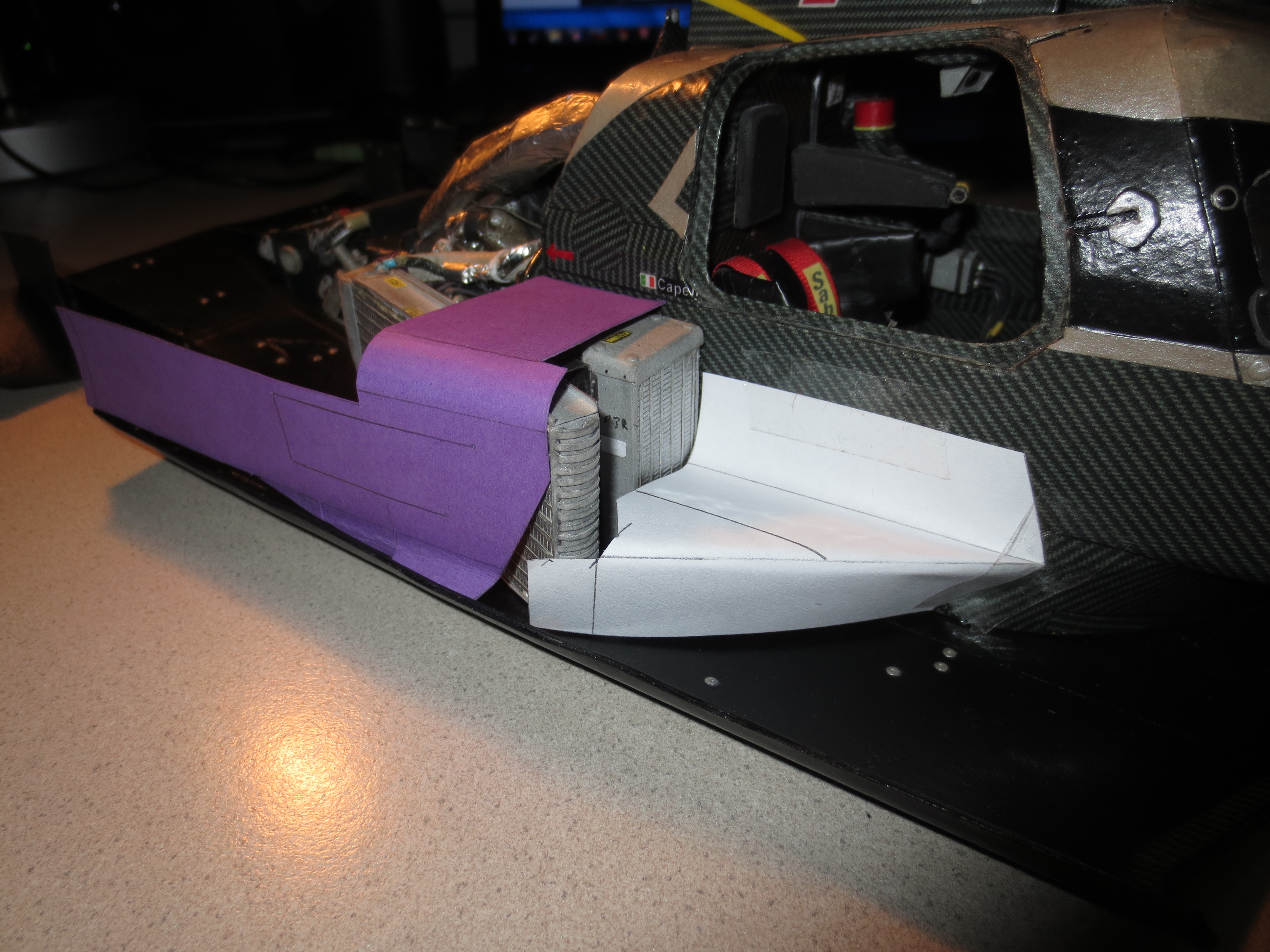

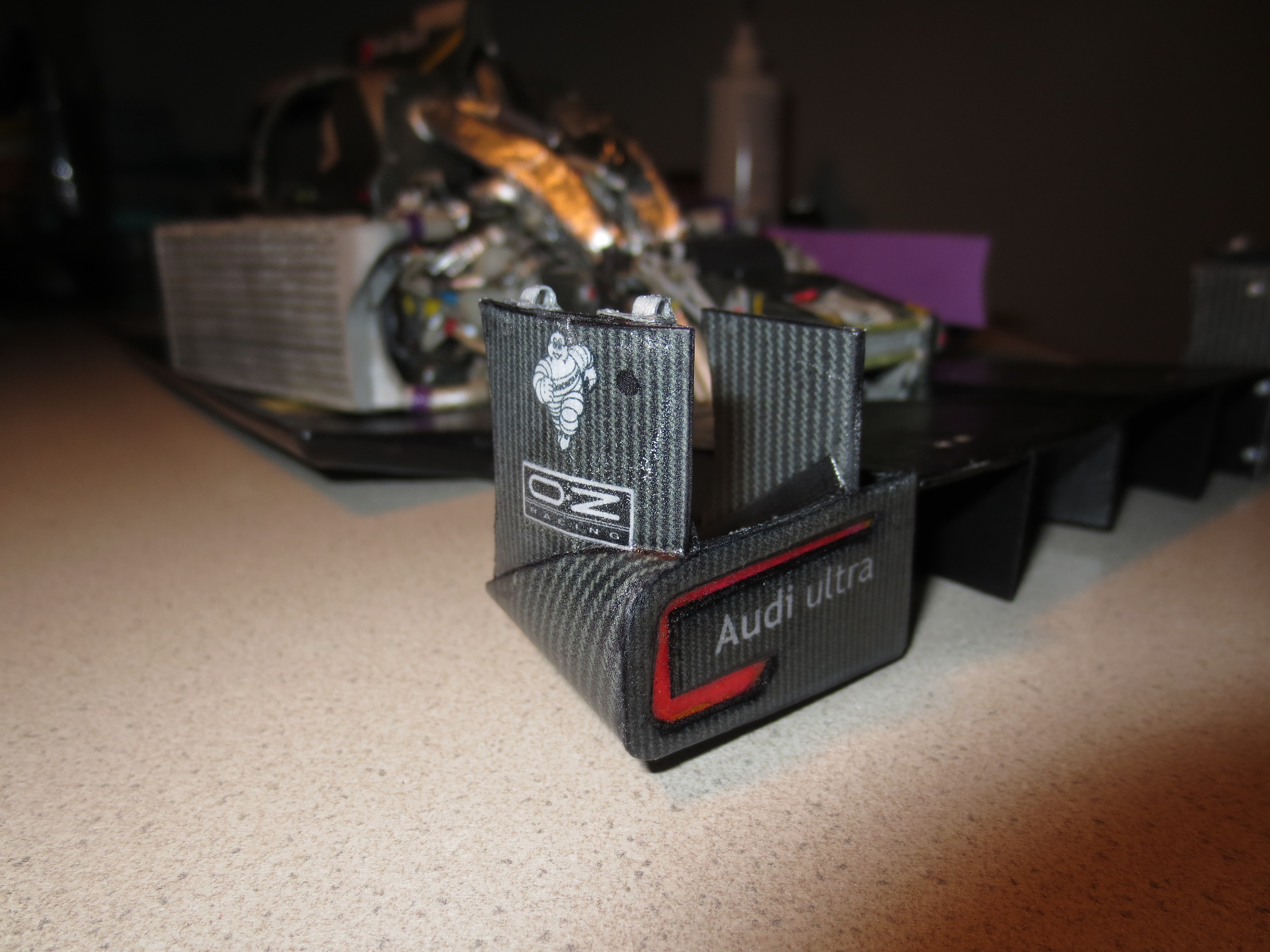

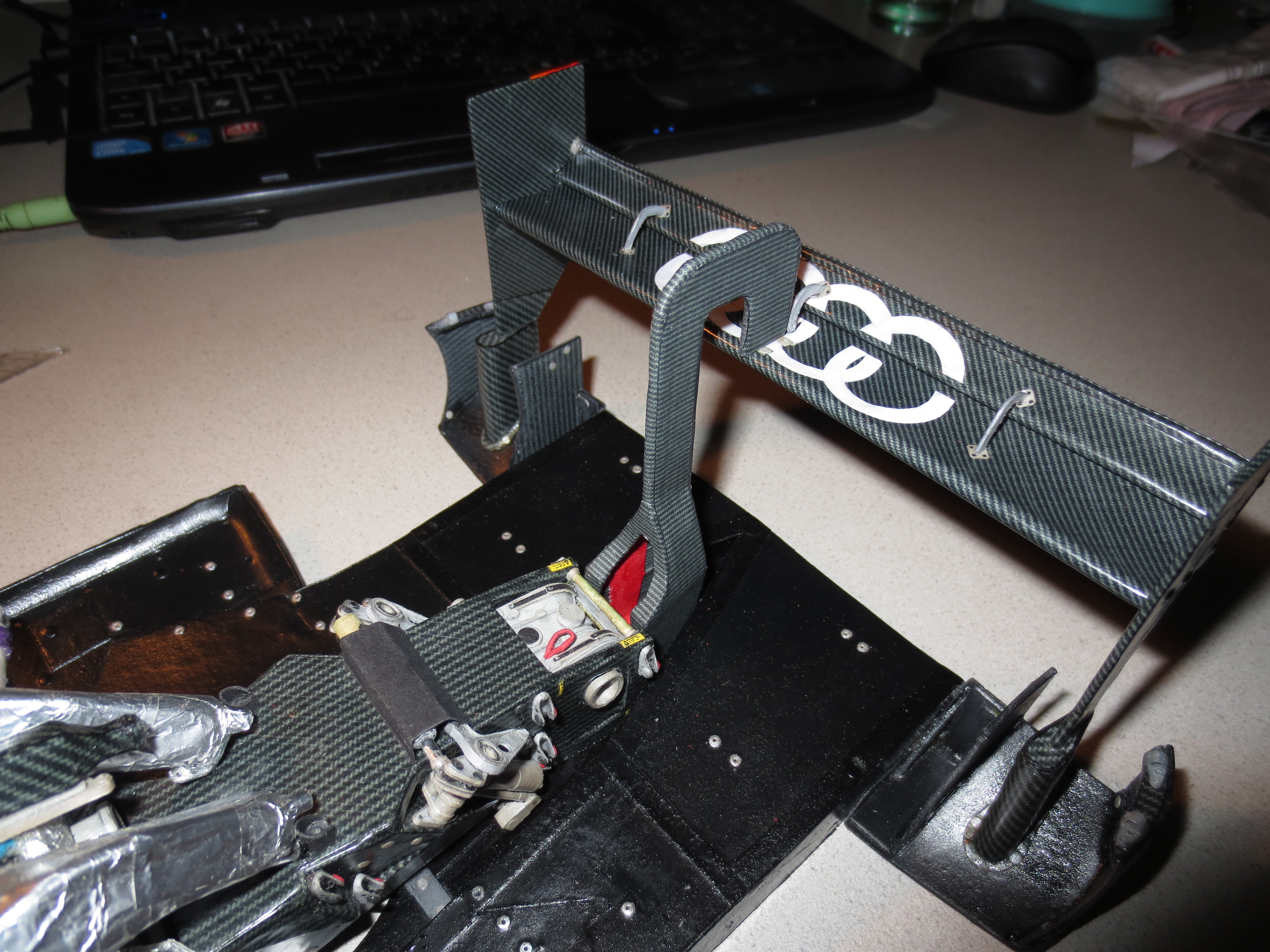

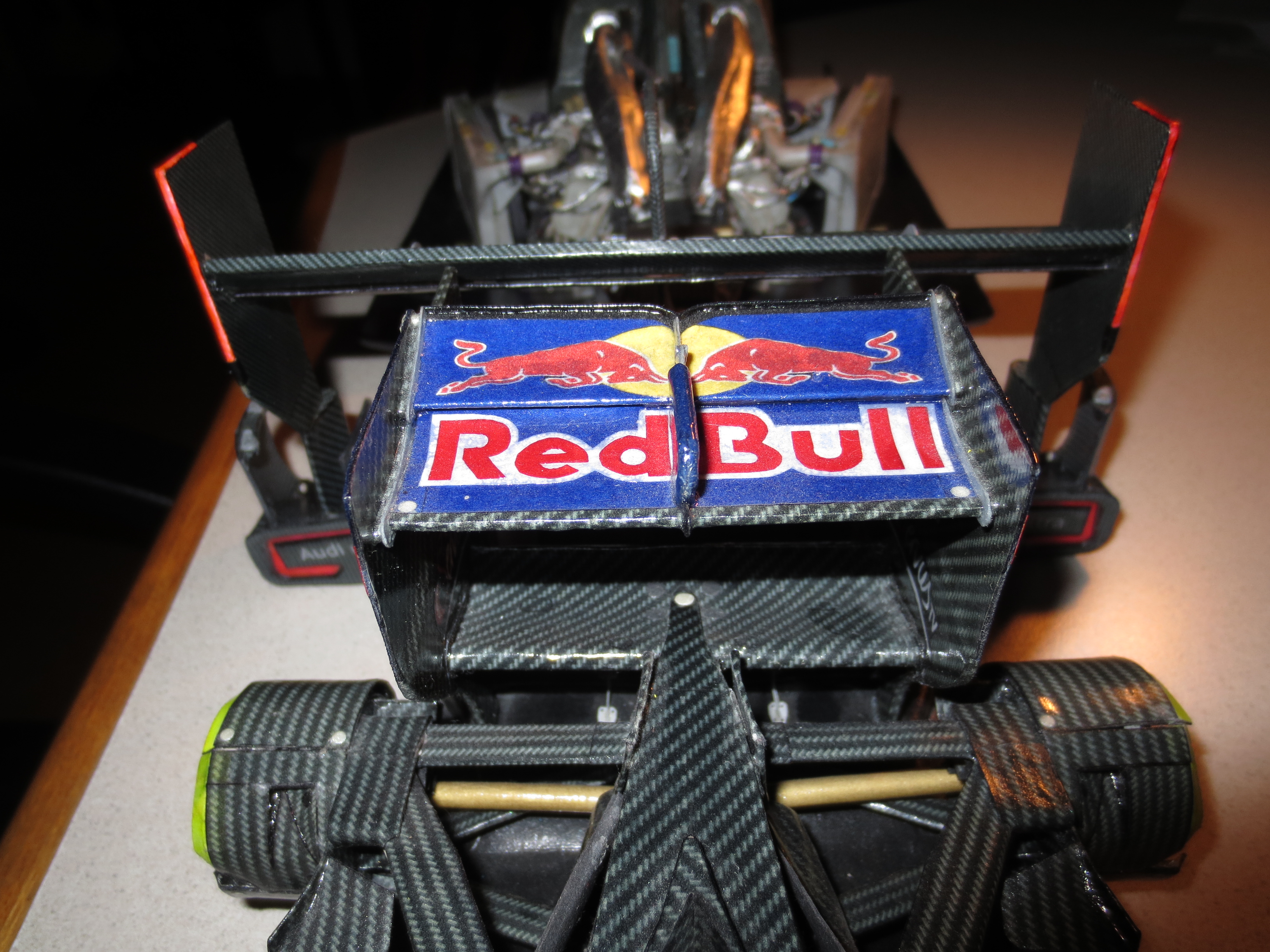

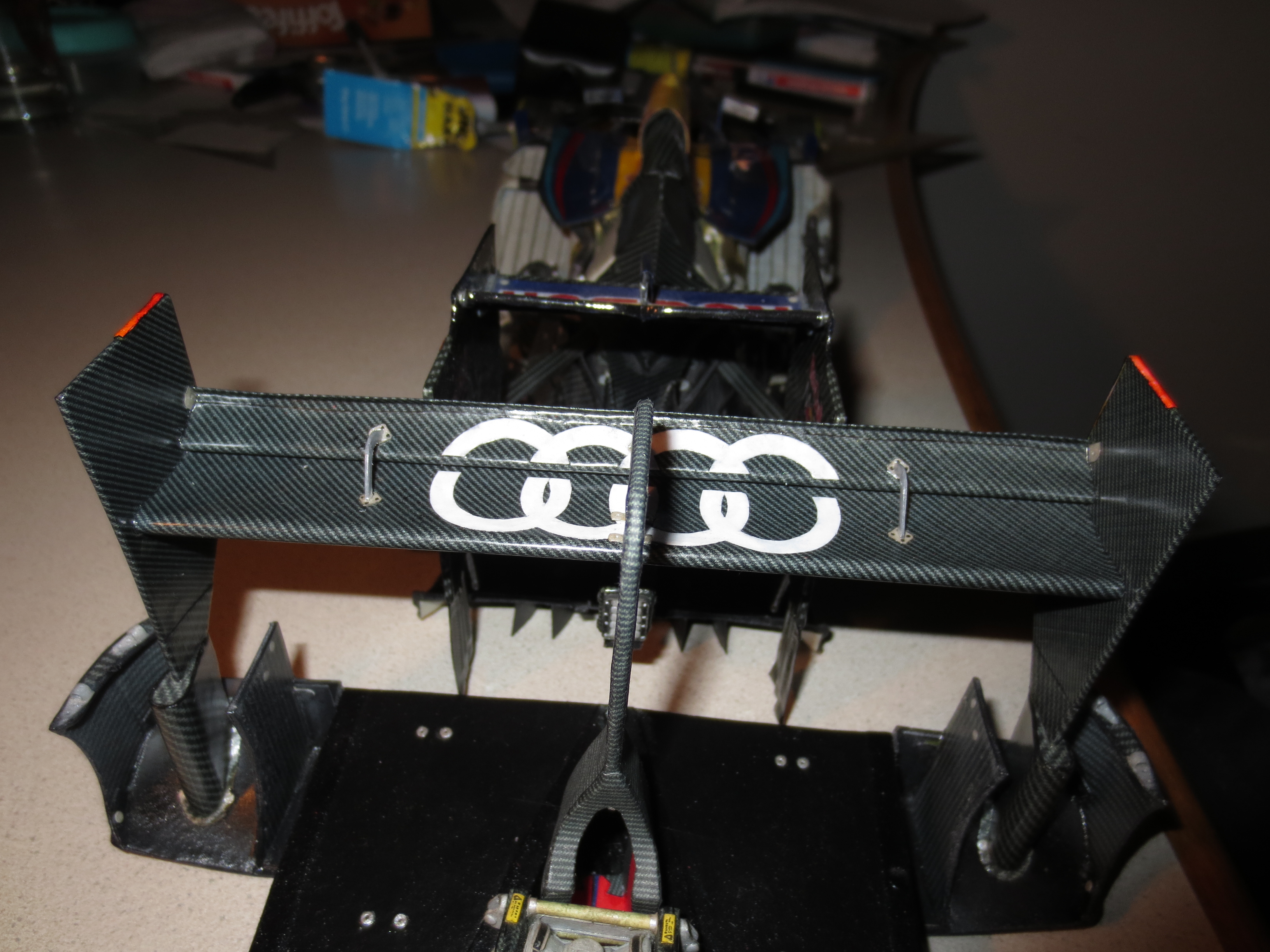

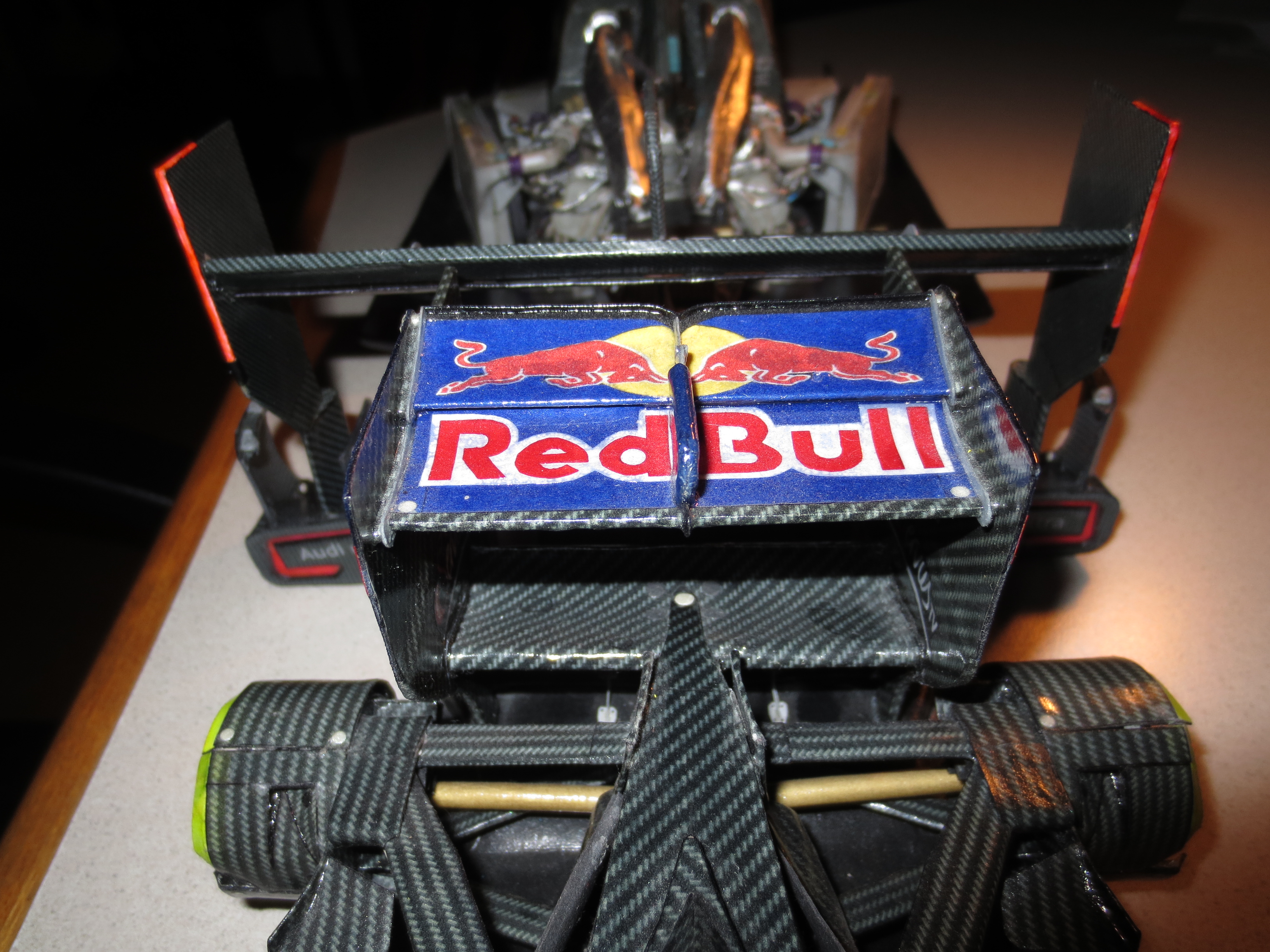

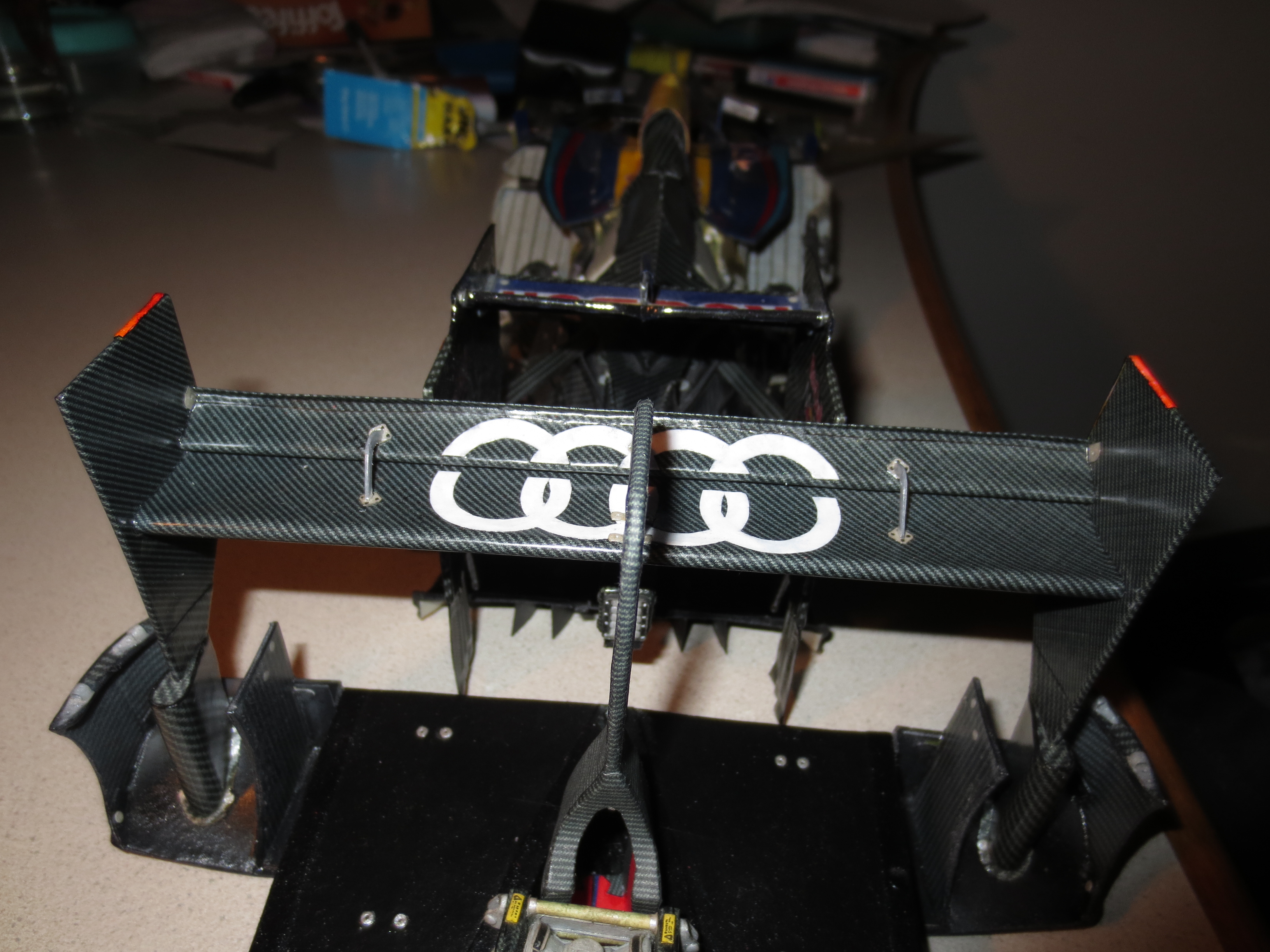

Rear view of the two cars (Red Bull RB7 and Audi R18 TDI). Even here you can see the enormous difference between the dimensions of these two wings. The Red Bulls wing is in Monza configuration, the Audis wing is in Le Mans configuration. So, both cars drive with very low downforce.

Here’s a nine pic to compare these two wing types visibly.

The wings projected area viewed from above is about 245.000mm² for the RB7 and 240.000mm² for the R18 TDI. You can see, even if the F1 wing has not half the width of the LM wing, they have both about the same surface.

Current F1 rear wing elements are quite similar to LM wing elements. A few more small details, but not really different. The cross section of the wing elements is a bit thinner and not that much like a standard wing section like it is at LM cars.

Even a LM car is 80mm higher than a F1 car, the rear wings are allowed to be at almost the same height. 950mm at F1 cars and 965mm at LM cars (although Audi does not exploit the full height).

At the end plates, you can see a really big difference. Where the LM end plates are really only there for closing the wing, the F1 end plates have great aerodynamical influence on the cars rear end. I’m no aerodynamicist and I won’t strike out trying to explain this circumstance, but I think it’s clearly visible, that the EP’s function is not only there to closing off the wing.

That's it, thanks for watching,

Cheers,

Paul