You write:

"Superficially at first glance yes. But that version is countering the back shift resistance by further forcing load onto the front driven pulley. The compression forces within the belt as it passes over that pulley will be increased - possibly to its detriment."

The typical modification of a scooter (there are millions of them on the roads) is the substitution of the variator (governor) by an “aftermarket” having different characteristics than the original one.

In most cases the rider is looking for something improving the performance of his scooter. Then he regrets, because there are side effects, but it is late.

The original variator of a scooter is, typically, a compromise for:

relatively acceptable fuel efficiency (mileage),

relatively acceptable acceleration,

relatively acceptable final speed,

relatively acceptable reliability,

relatively acceptable climbing ability,

relatively acceptable NVH (noise vibrations harshness) properties etc.

For better mileage, quieter riding (long trips on the highway), improved reliability and the similar, the CVT should keep the engine at substantially lower revs. But then the acceleration, the climbing capacity with heavy load, the overtake ability and the similar are hurting.

If, on the other hand, the focus is on the performance, on the safety (accelerations, faster overtake etc) the CVT has to keep the engine at higher revs, which means that the mileage drops, the noise – in a long ride – gets exhaustive, the reliability worsens etc.

During a long ride on the highway, a rider who replaced his variator by a sporty one, or the "weights" of his original variator by lighter ones, is missing his previous CVT setting.

During an acceleration / overtake, the rider who didn’t replaced his variator by a sporty one, regrets for his choice.

In most cases the rider of a scooter (just like the rider of a car; think: when it was the last time you operated your engine at its peak power revs?) needs longer and way longer transmission ratios.

Only from time to time (say during a fast ride, or a dangerous overtake) the rider of the scooter does need shorter gear ratios to get the most from his engine.

Suppose you have a scooter and you want to get the best from it, without compromises.

You start by replacing the variator with one providing longer transmission ratios (you can alternatively replace the weights of the variator by heavier ones).

The longer-geared-CVT keeps the engine at lower revs, the fuel efficiency is higher, the noise drops, the scooter gets more reliable.

However, when you want to go faster, when you go overloaded on an uphill with strong opposite wind, when you need to overtake a long truck, things get from tough to dangerous, making the long-geared-CVT a bad choice.

Now let’s see how the PatBox can improve the above long-geared-CVT scooter.

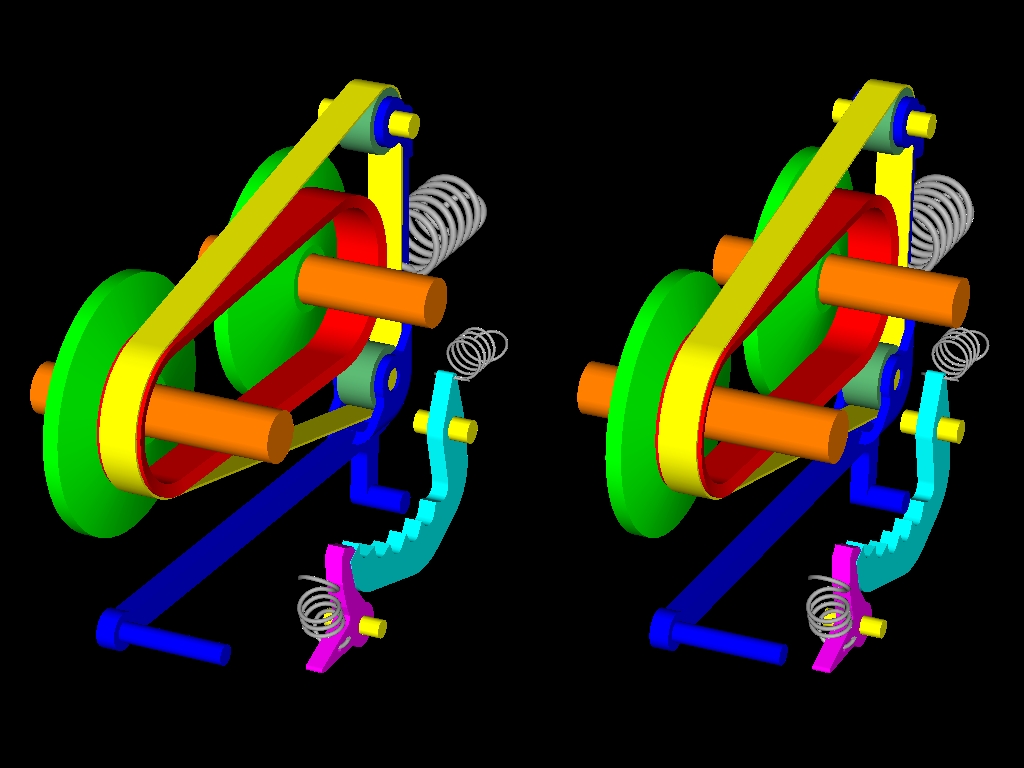

By adding an auxiliary belt and a lever, the CVT turns to PatBox (stereoscopic representation, more on how to look at it at http://www.pattakon.com/pattakonStereoscopy.htm ) :

The auxiliary belt is “standby”.

It rides around the external periphery of the V-belt and follows its rotation without resistance (or, more correctly, with very small resistance / friction, because the auxiliary belt is not transmitting any torque; all it does is to push the V-belt deeped in the front pulley, and this is necessary only when the long-geared-CVT proves too long for the existing conditions).

Any moment the rider needs a faster acceleration than what the long-geared-CVT can offer, he just presses the PatBox lever and the auxiliary belt pushes the V-belt deeper in the front pulley.

Alternatively he can “preload” the spring that pulls the lever that pulls the auxiliary belt (this means “automatic operation” with shorter gear ratios, which is one of the characteristics of the PatBox: it can run manual or automatic).

The overall gain in running cost (fuel, V-belt wear etc) and quietness is more than significant, without sacrificing the safety or the performance.

Do I miss something?

What are the problems you see in a modification like the previous?

If the PatBox achieves the reduction by, say, 25% of the running cost of a scooter, on the expense of a heavier pressing of the V-belt in the front pulley from time to time, isn't the pain worth the gain?

Here is a couple of comments on another forum (Mopeds Army) from the guy (a third party) who first made, and tested on his 50cc moped, a PatBox CVT :

“This design is not difficult to make at all, and shifts like butter.”

and

“As for eating power, it might, but my bike is faster now.

I can say that my hobbit is faster now than it was before.

Substantially.

Not having to accommodate for rpm drop at high speeds because you can manually adjust opens so many new tuning avenues.”

Thanks

Manolis Pattakos