Hello Pinger.

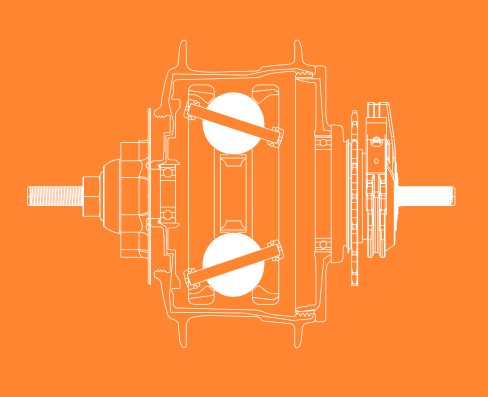

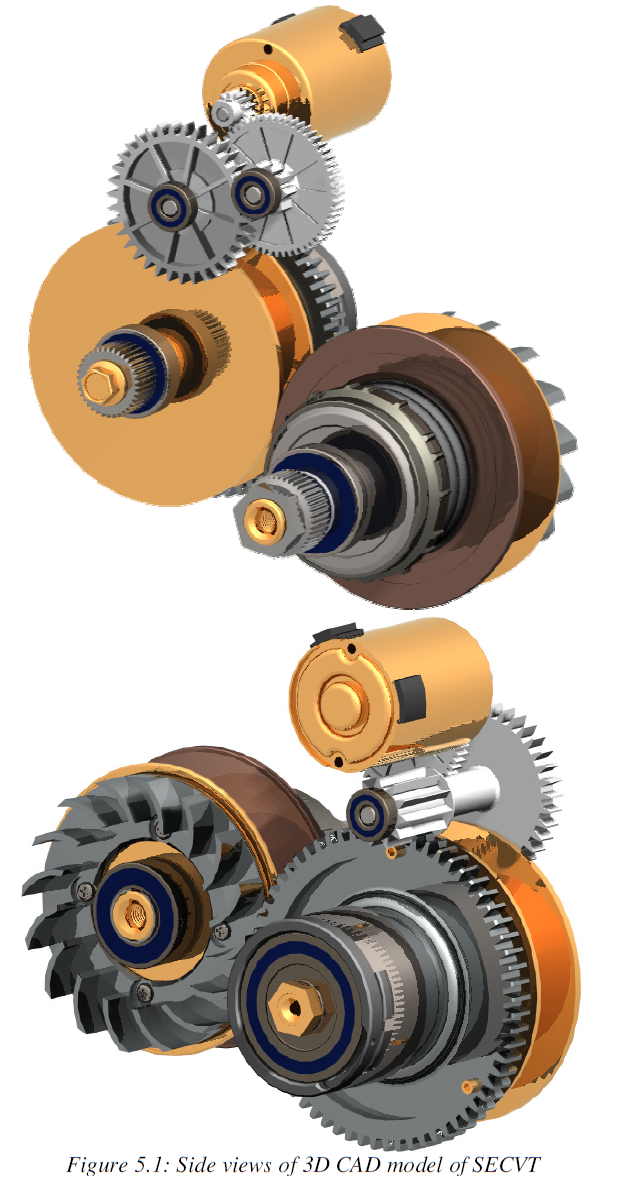

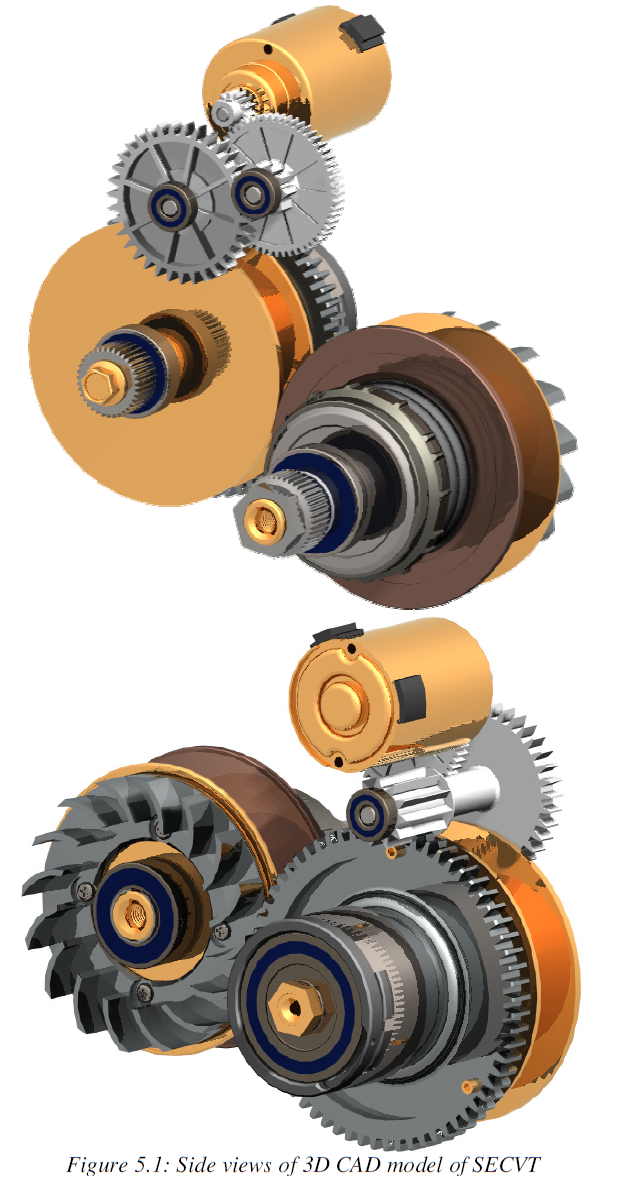

The Suzuki Burgman 650 SECVT (Suzuki Electronically-controlled Continuously Variable Transmission) is the first scooter with electronically controlled CVT.

Quote from

http://www.suzukimotorcycles.com.au/ran ... eaturesfor the Suzuki Burgman 650 SECVT:

By just toggling buttons on the handlebars,

you can choose three distinct transmission modes: two fully automatic modes (Drive and Power) and Manual. Drive mode heightens efficiency at normal road speeds and gives smooth, linear, almost shock-free power delivery for easy riding. Power mode gives more punch when you twist the throttle. And Manual mode lets you thumb-toggle between five preset gear ratios for a unique feeling of control.

All new Eco Drive Indicator to encourage riding that may reduce environmental impacts.

The Eco Drive Indicator light, located on the instrument panel, will come on when the vehicle is operated in a fuel-efficient manner - and may help riders learn techniques to improve their fuel economy.

End of Quote.

Several years later, Aprilia, under the license of Suzuki, created the Aprilia Mana 850 (SECVT), which is something between motorcycle and scooter (the final transmission is by chain and sprockets).

What the “controllable” SECVT offers as compared to the conventional “uncontrollable” CVT’s of scooters and sleds?

It offers control.

Control over the fully automatic operation: because the rider can choose between different modes of operation (a drive mode (for economy) and the power mode (for performance)).

Control over the manual operation: “Manual mode lets you thumb-toggle between five preset gear ratios for a unique feeling of control.”

It also offers to the rider ways to achieve greener operation (EcoDrive Indicator).

And why the rest scooters are not using a SECVT to improve their economy and performance?

Because it is too expensive. It adds some US2,000$ in the price of the Suzuki Burgman.

And because its complicated structure and control proved, in the long term, not trouble free (and quit expensive in repairs).

And what the PatBox offers?

Just like the SECVT of Suzuki, it offers control over the CVT.

As in the Suzuki Burgman 650 SECVT, the PatBox offers a number of fully automatic modes (economy mode, power mode etc), also a sequential “manual transmission” mode, also a continuous manual mode (not offered by the SECVT).

As for the increase of the cost of a scooter with the PatBox, it is more than a dozen times lower that the cost added by the SECVT of Suzuki.

And because of its simplicity, and of the way it functions, the overall reliability of the scooter or sled improves.

Regarding the sleds:

No matter how sophisticated the clutch of a sled is,

it is just a mechanical clutch.

And as such, it cannot guess what the rider / driver really wants.

If it could, Suzuki’s and Aprilia’s engineers would be stupid to add the complication and cost of the SECVT to get the same a sophisticated clutch of a sled can offer / do.

So, the sleds, just like the scooters, do need control over their CVT’s. They will be better vehicles when their “uncontrollable” CVT turns to “controllable”.

Worth to mention here:

As the auxiliary belt presses the V-belt deeper in the front pulley (in order to provide a shorter transmission ratio than the ratio the CVT gives at the specific revs and load), the over-clamping of the V-belt in the front pulley increases, while the over-clamping in the rear pulley decreases (because the spring of the rear pulley extends).

If we start with a long-geared-CVT, when the V-belt runs at smaller diameters in the front pulley (because the auxiliary belt of the PatBox pushes it deeper), the additional over-clamping in the front pulley is welcome / necessary.

EDIT PS:

In order to turn a CVT into a long-geared-CVT, one can replace the "weights" of the variatorr by heavier ones, so that, at the same rpm, the centrifugal forces acting on them to increase, which in turn causes (by the weights moving on the ramps of the variator) the axial force on the movable half of the front pulley to increase, which in turn pushes the (constant length) V-belt to run at a bigger diameter in the front pulley and, consequently, at a smaller diameter in the rear pulley, which in turn causes the further compression of the spring of the rear pulley.

Another easier method is the replacement of the spring of the rear pulley by a softer one.

At normal conditions of operation, the softer spring enables longer ratios, it reduces the over-clamping of the V-belt and the CVT runs at lower friction and less wear of the V-belt.

And when the rider wants more (faster acceleration, motion along a steep uphill etc), he can, by means of the auxiliary belt and of the lever of the PatBox, press the V-belt to get deeper in the front pulley.

This increases the over-clampring in the front pulley (wherein the V-belt runs at smaller diameter), this also increases the amount of torque the V-belt can absorb from the engine without slipping.

The lower over-clampring of the V-belt in the rear pulley (due to the sofet spring) is OK because at the rear pulley the V-belt runs on bigger diameters when the transmission ratio gets shorter.

Thanks

Manolis Pattakos