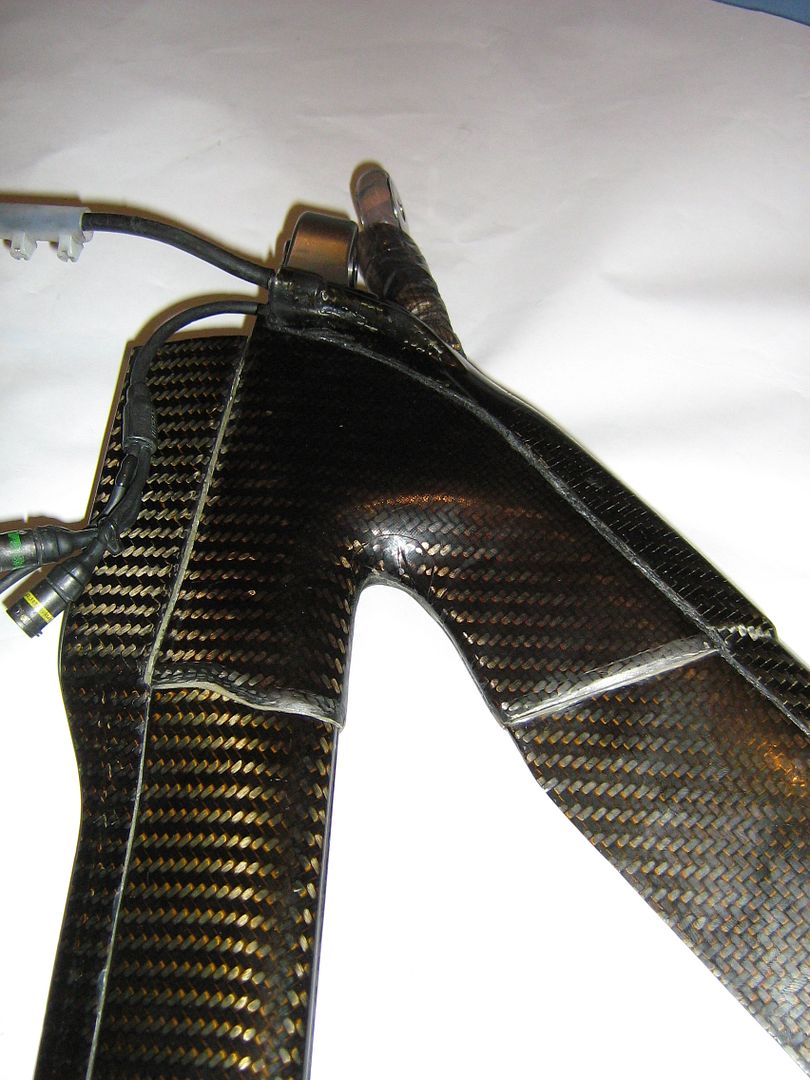

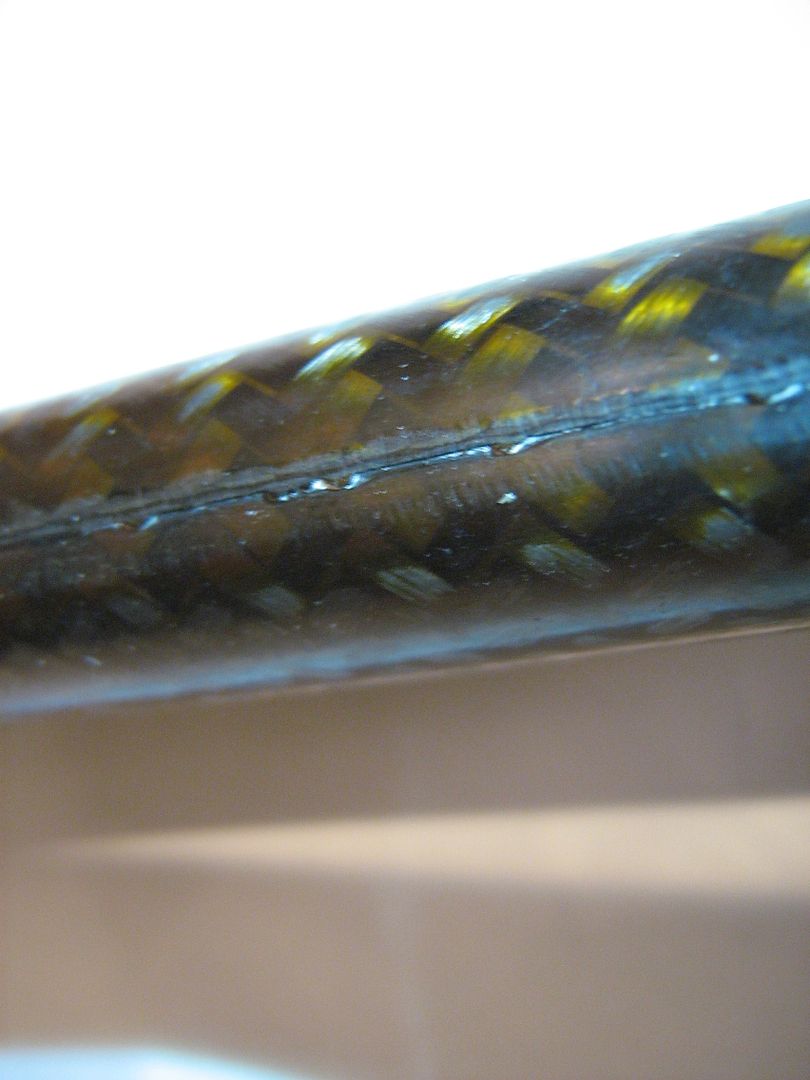

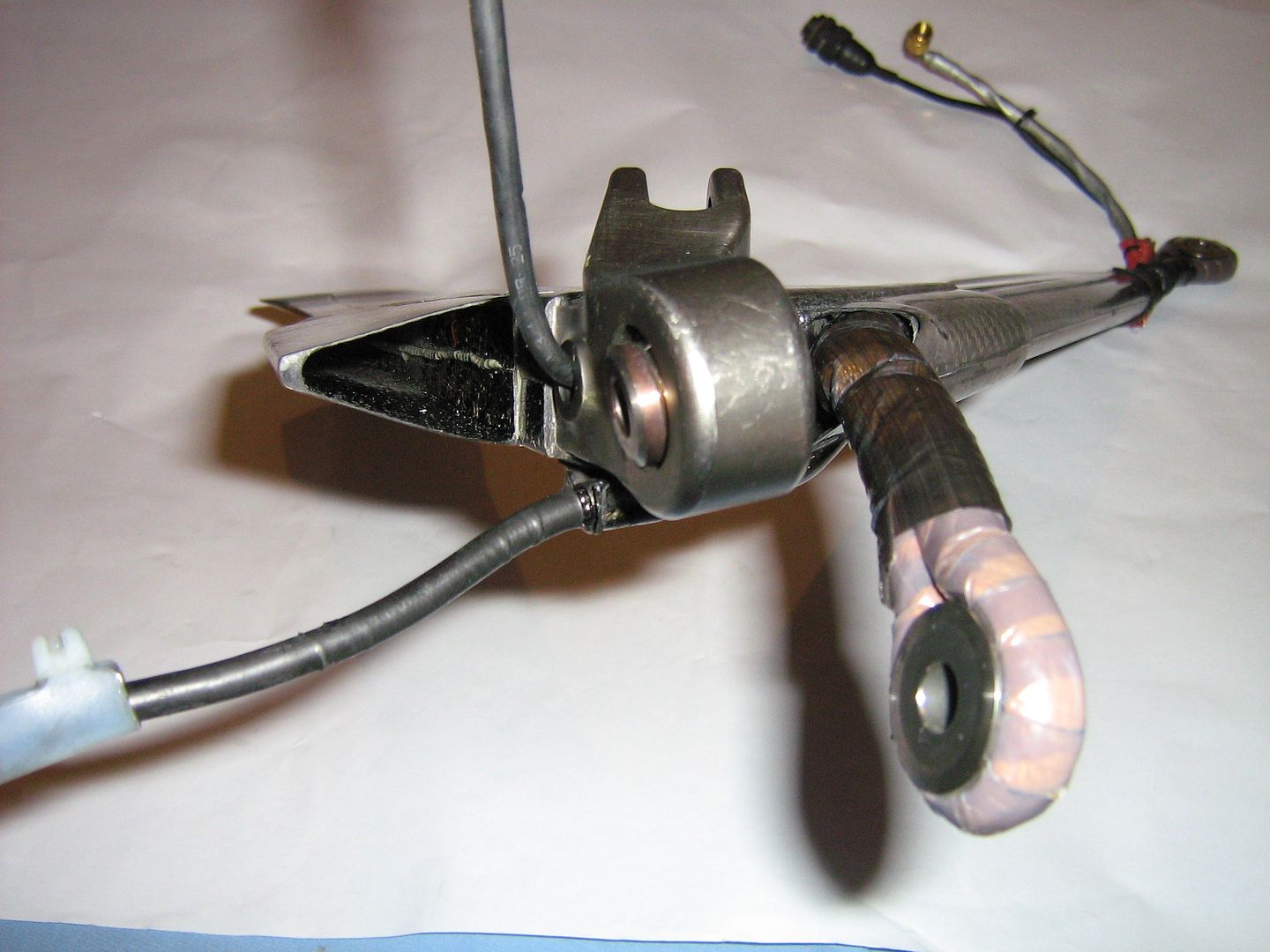

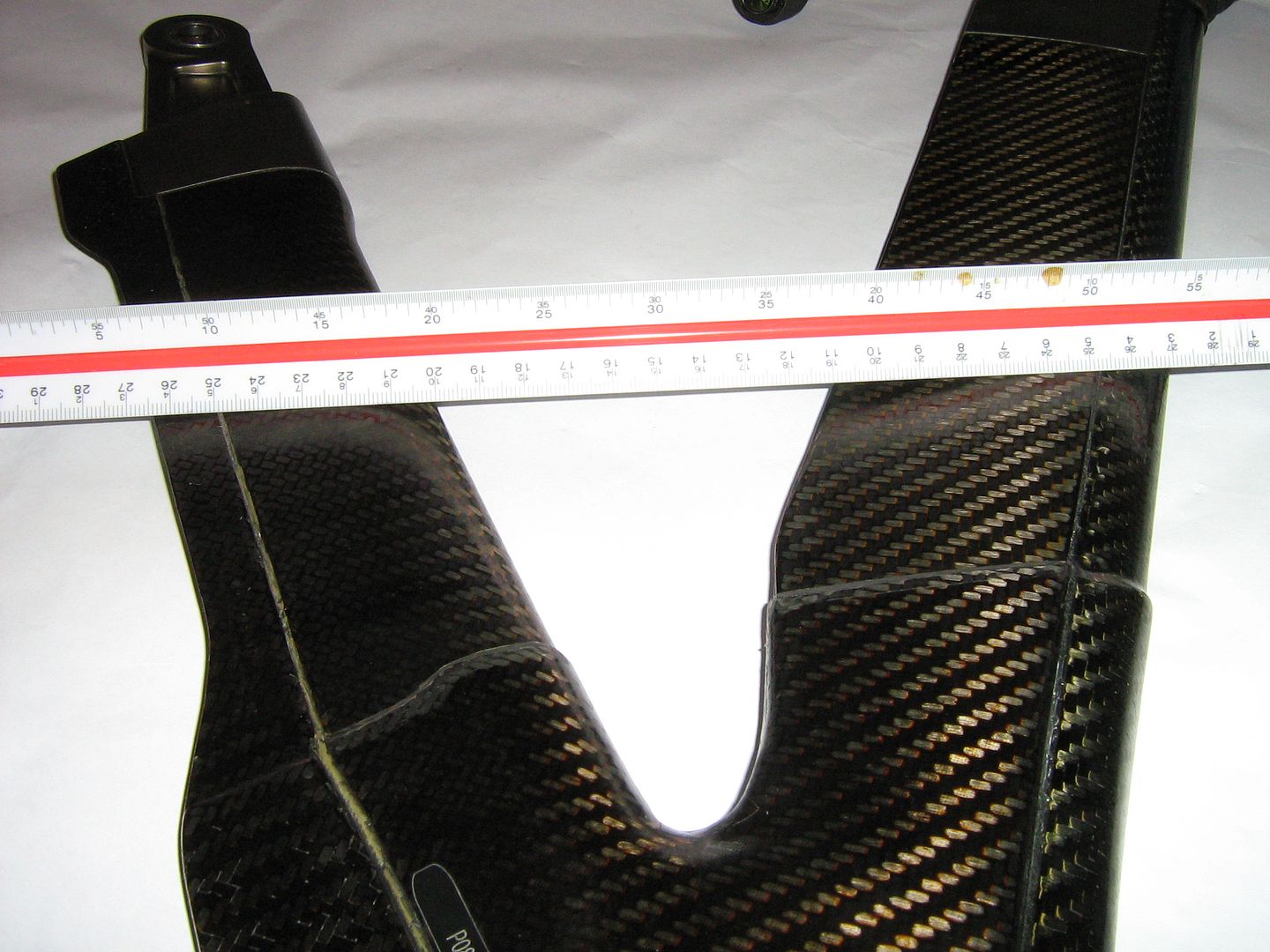

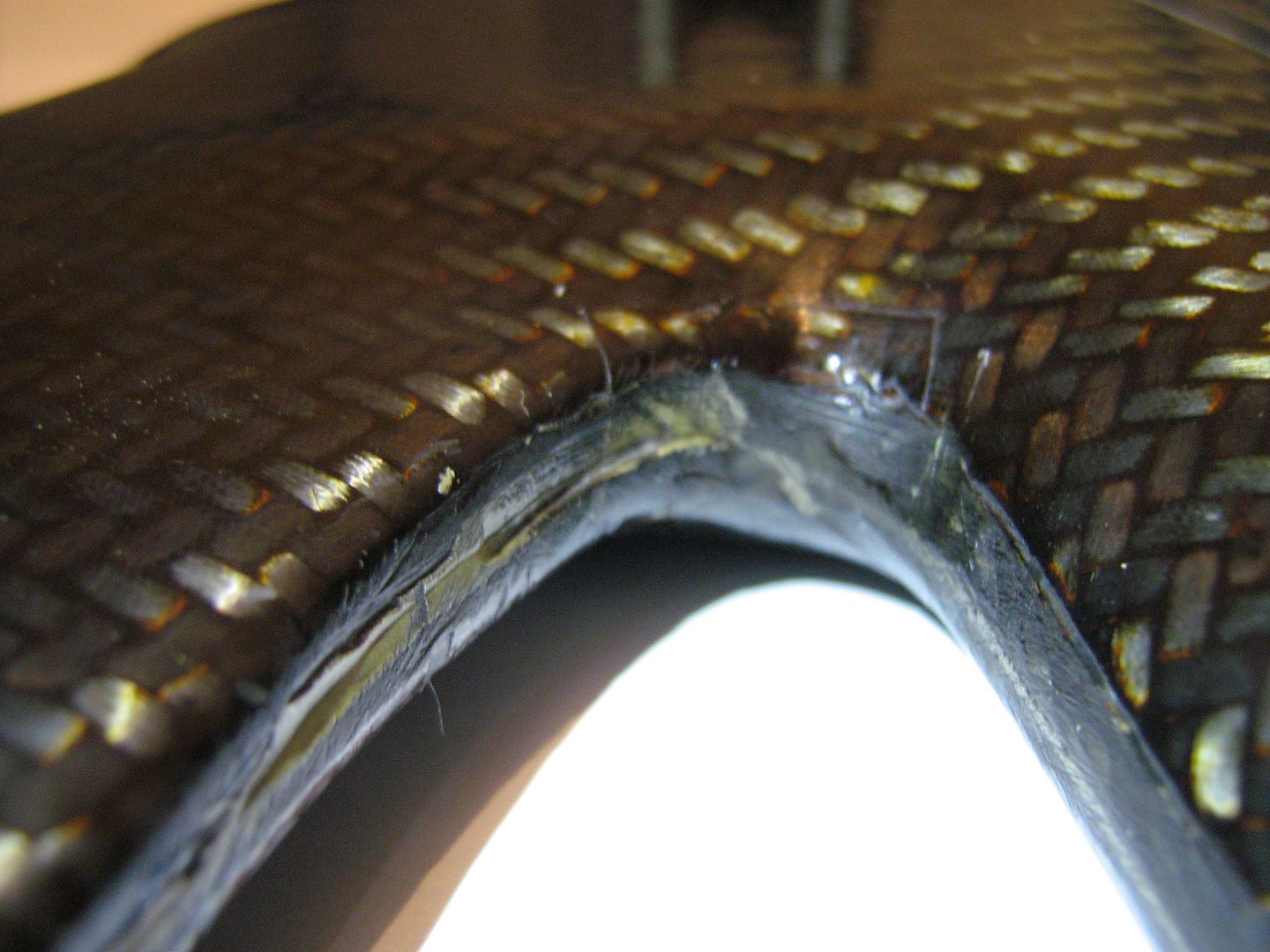

In this thread over the next while Ill be unlocking a few secrets hidden within this part. Mainly, its construction, and how it was made. I will be cutting sections from it, and carrying out some destructive testing so anyone who is nervous, or cannot bare to see this sort of stuff cut up then leave now, its not the thread for you, if you have a keen interest, then this is the thread for you.

To my knowledge, this is the first time this will be done in the public domain.

I do not work in any F1 company, and have bought these parts legally, with my own money.

I have read all disclaimers in reference to second hand F1 parts and what I am undertaking is legal.

I am not going to mention the makers name all the same, just Incase Ive missed some small print. If any members want to guess as to which car(s) the parts belong(there will be more than one)then guess away, but I will not admit to whether you are right or wrong.

I have contacted F1 technical a few days ago in the light that they would give me some form of into before I posted up all this, but sadly, I got no response.

So Ill do a little self intro just so you know me a bit better given that Im new on here. I know just one other guy on here from my neck of the woods.

I have a keen interest in Motor-sport parts as well as Metallurgy, and Mechanical engineering. I have also an extreme Interest in petrol n/a engines, and head design.

I am not qualified in anyway but have been researching all this stuff since I was about 8, and have continued to do so to the current day. I have designed and made many parts at this stage mainly from cast aluminium. Doing everything in house from pattern making to machining. The latter started as a hobby/evening work but now, I can see how I may be able to make a living from it in the future.

This year I hope to cast my first 16v cylinder head, doing everything from design, to mould making/pouring/machining etc, myself. I had intended doing it last year but other stuff got in the way. I have the design done for some time now.

I spent a lot of time as a joiner, which makes complex pattern making easy for me.

The rest is passion.

So thats me, I hope you enjoy and perhaps learn a bit from what I bring to the table. Im doing this analysis for myself, but I feel it would be rude not to share.

If you feel the info is good, or that you have learned something you didn't know, then feel free to wire me money, I wont say no

Anyway, enough chit chat, onto the first of the photos, enjoy and Ill update daily, or when I can, dont worry with the first batch if you cant figure out the carbon weave or how its laid/moulded up, Ill find out/display all that.

Brian Garvey.

Something to be thinking about for the time being...

(internet picture)

(internet picture)