Formula None wrote:ringo wrote:

It's not any weaker.

I'd like to see your source for that. I really doubt sintering or casting would not produce a thin part with properties comparable to sheet metal.

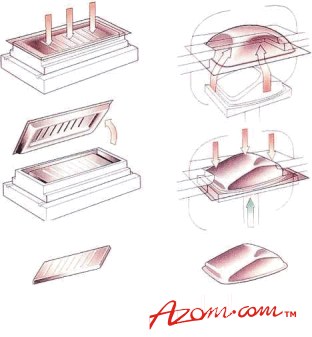

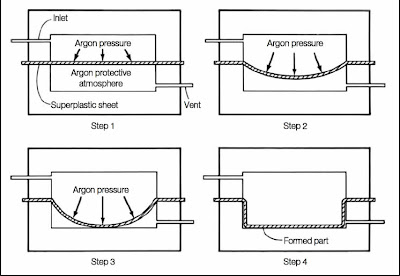

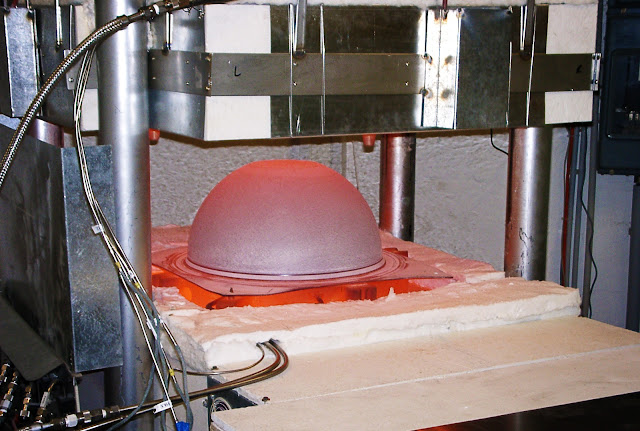

Superplastic forming isn't "hand forming", we're not talking presses and brakes here, it's basically thermoforming with sheet metal. Agree though, dies take time to make which was my initial reservation about how it was claimed have shorter lead times. Sometimes the advantage, depending on process and part design, is that only 1/2 the die needs to be made (compared to stamping or laying up CF), one female cavity. High pressure gas on one side of the mold forces the heated sheet into the mold. So maybe some time was saved in mold simplicity. Other times you have a full mold and its more similar to stamping with dies, sometimes you even have two sandwiched sheets that are blown into with compressed gas (similar to hydroforming or plastic blow molding).

The sintered titanium is not any weaker thanks to the grain structure.

It deposits the metal at 100% density. The grain structure of a sheet or casting is not at this level of perfection.

http://www.techbriefs.com/component/con ... ticle/2787

sintered in blue:

Any how you look at it, even if it was weaker, a diffuser doesn't need a whole lot of strength anyway, it just needs to be tough.

That die and press you have there, i am not sure if Mclaren have 1 such as that, and since they are making 1 part instead of thousands, it's not likely they would have that infrastructure in to make 1 diffuser.

Another possibility and quick process is investment casting. Mclaren can rapid prototype a mold, fill it with wax, ceramic coat the wax, and send it out to be poured at some steel mill if they don't have an induction furnace.