I was in two minds if I post this or not but looking through the engine picture thread gave me some motivation.

Ive been ranting and raving about designing and casting my own cylinder head for about 7yrs now. Every year I thought I was ready to start I either figured out something else I knew Id have to find out, or else come up against a problem when trying to design the thing. Its been a long and sometimes steep and frustrating slope at times keeping in mind that in that 7yrs I had to setup a small foundry and all that goes with that, and also locate a load of different companies that would sell me what I needed in small amounts. In that time I also purchased a cnc which I had to retrofit to modern controls which also meant learning about computers at a very basic level down to 1's and 0's, to learning about software packages to a some what higher level. Every thing you learn as you go means you have to learn seven other things to fully understand that first thing. Servo motor fundamentals was one as with a retrofit you have to tune said motors and so on. All this just to cast a cylinder head.

In the early days I worked on a bridgeport so the basics of machining I had pegged, but, with a cnc hitting cycle start and entering feeds was a different story entirely. Obviously you dont need a cnc to machine a cylinder head, but the accurate positioning helps loads.

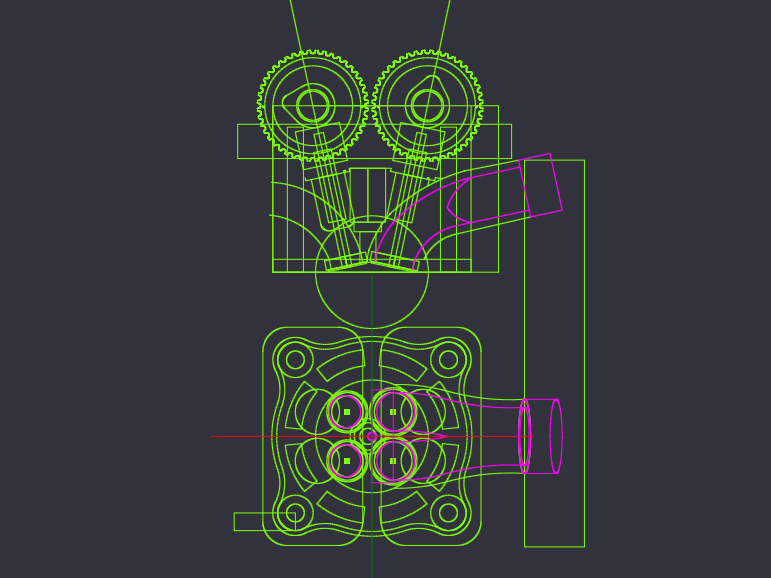

In 7 odds years I have only cut moulds in 3d form on the mill a handfull of times. I find it quicker to just work off 2d drawings and build up the mould boxes that way - cutting whatever bits I need on the mill in 2.5D so to speak.

I know this sounds silly, but having trained as a cabinetmaker many moons ago making the mould boxes just comes easy to me. I guess whatever works, works.

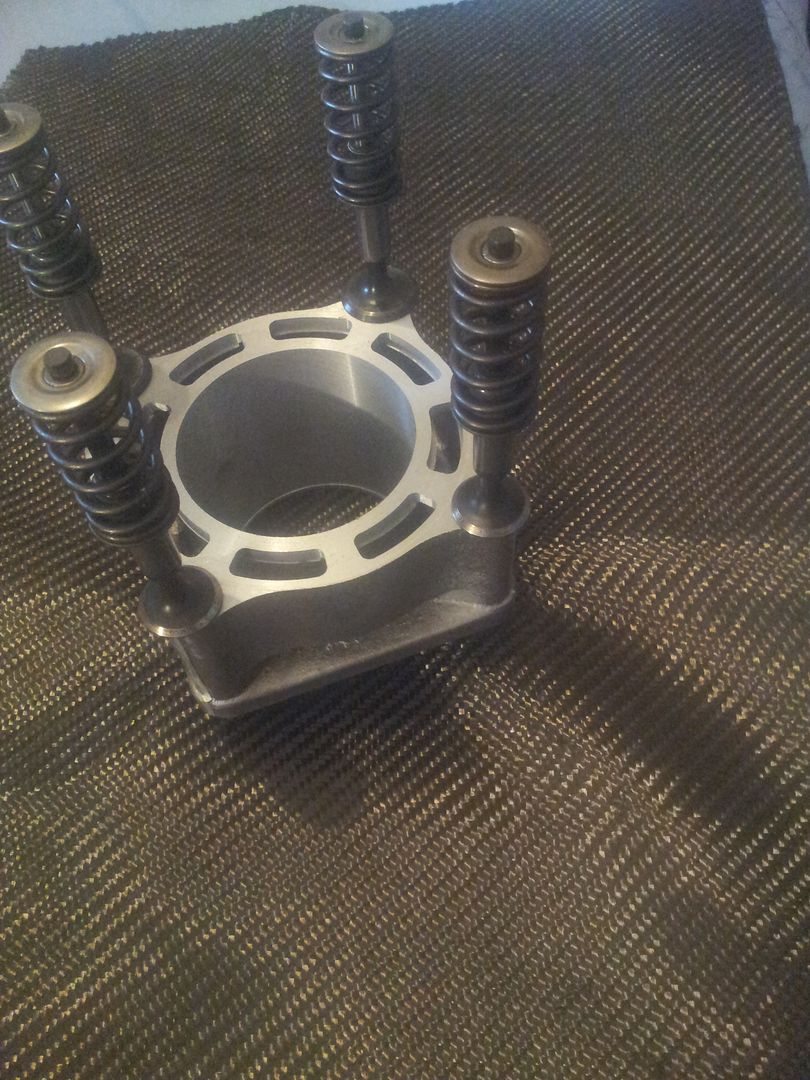

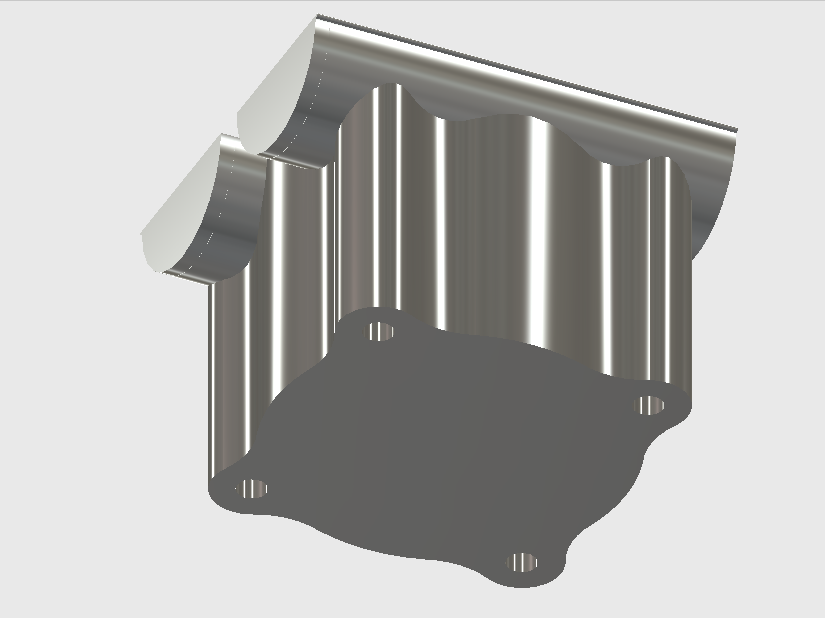

Approximately a month ago I decided that a single cylinder engine would be a good Idea as a layout test for various parts within the head. Given the fact that it will have twin overhead cams, and four valves nothing will be that different in terms of casting the inline 4 16v head - which I hope to bolt onto a Mk2 Golf Gti block whenever its ready.

Its important to note that this single cylinder engine is not so much about the perfect head design, or the perfect engine design, rather its about a fairly good design that can be improved but that contains the critical elements in terms of mould building that the 'good design' inline 4 head will have.

Its also about materials and material durability, tolerances, and general reliability in terms of running.

Since I have no inertia dyno, or am not into bikes, its going to be tested on the lake near me in the form of an outboard engine.

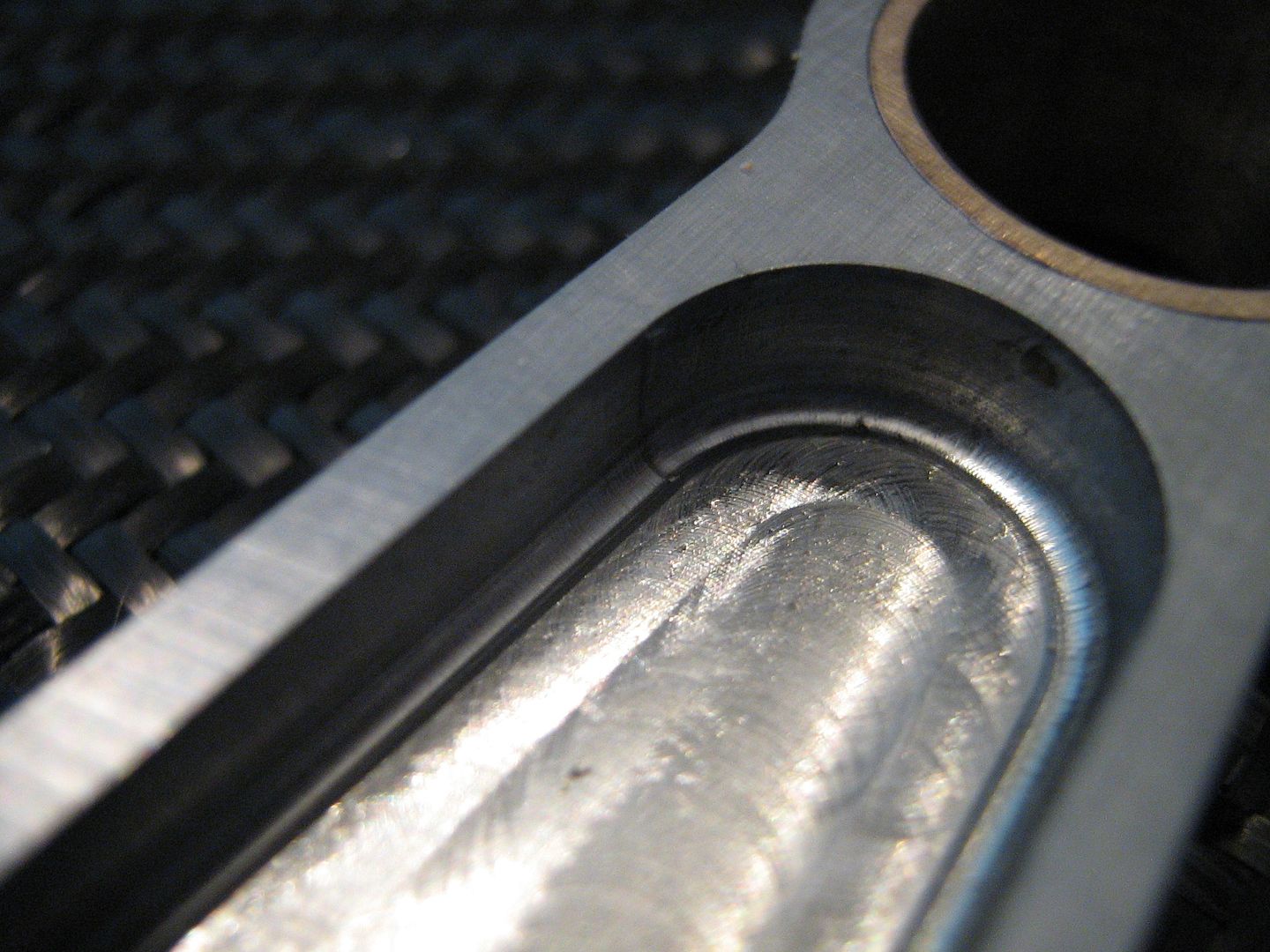

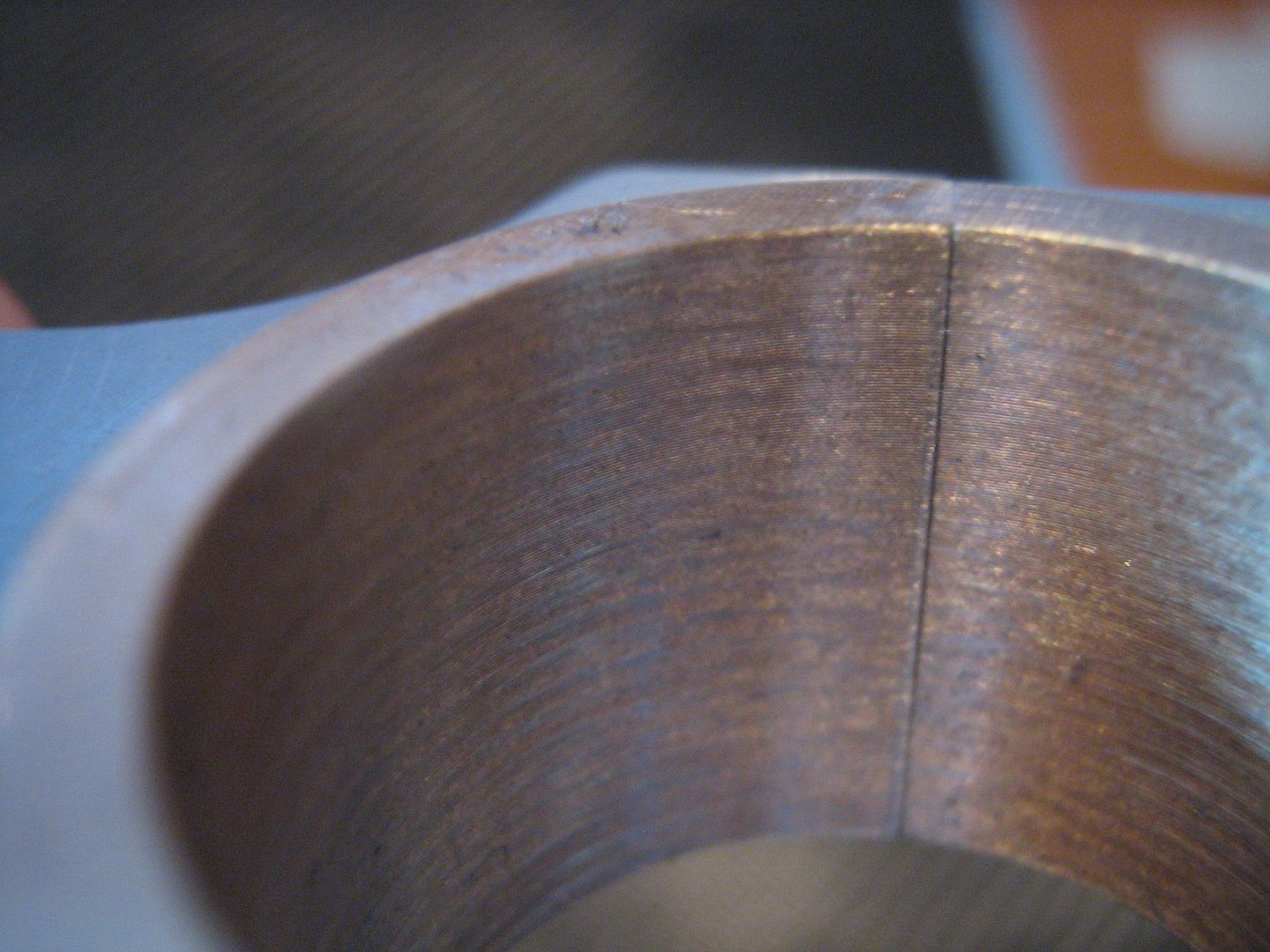

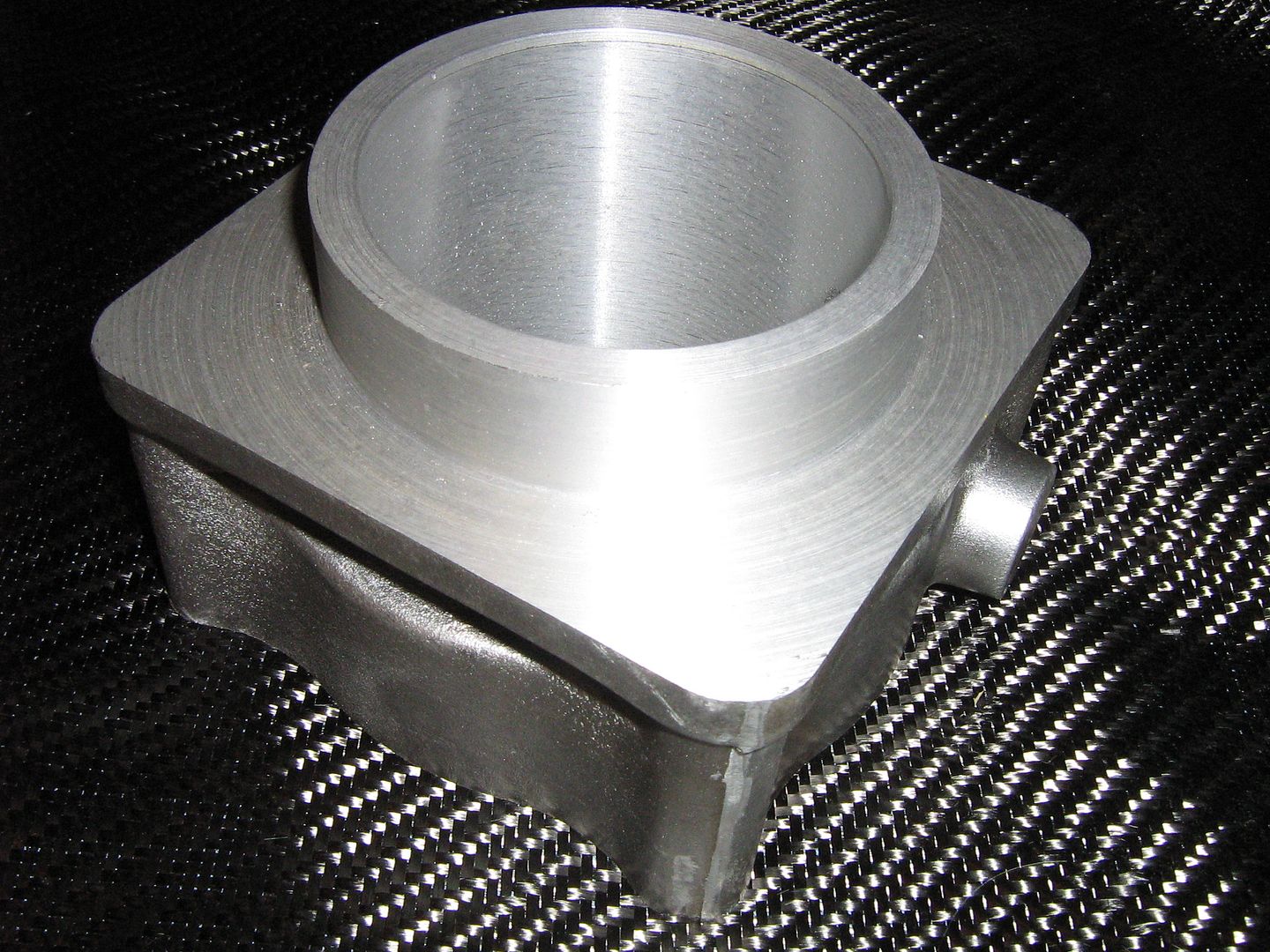

The engine will contain a 3 piece balanced crank, steel conrod, billet piston, and sand cast aluminium crankcase, piston barrel, and cylinder head. To get over any coating issues In fitting a ductile iron liner to the barrel.

For fueling it will run a carb for simplicity, and something not yet figured out to control spark - Ideally advance would be good.

It will also feature pressurized oiling.

In terms of math, there is not much done with this. The dimensions fit various single cylinder engines across the board so an approx power figure can be guesstimated. There are however a few calculations done in terms of engine balance, and also the cross-section some parts need be be in various places so that the thing wont explode.

The barrel will be watercooled as well as the head and will pull its water from the outboard leg pump/onboard impeller and run a total loss coolant system via a stat as do all outboards.

As mentioned, this is a research engine, It is to research not power figures, but build ability, tolerances, wear, and also core shakeout/venting within the head coolant galleries.

Ill be adding to this between now and Novemeber-ish when Id ideally like to have it complete.

Ive designed and cast some pretty wild things in the past but none of them were what Id call 'my own'.

As for the reason, well there is no reason, some people like to play golf....Ive been craving to do this for 15yrs.

Brian,

- Login or Register

No account yet? Sign up