Hello Gruntguru.

Yes it is a 4 stroke, as most airplane engines.

Actually it is more than “4-stroke” if you consider:

the flow capacity,

the unlimited rev limit of the cylinder heads,

the lubricant-free cylinder heads,

the cooling of the cylinder heads,

the efficient scavenging of the combustion chamber during the overlap (no short-circuit between the neighboring intake and exhaust poppet valves),

the compact combustion chamber during combustion,

the considerably higher compression ratio (there are no hot sports into the combustion chamber during the combustion)

the combustion chamber shape fitting, among others, with the lean burn used lately in the F1 and with direct injection wherein the injector shoots the spark plug,

the friction free operation,

the elimination of the inertia and of the impact loads,

etc.

A few weeks ago, in the

http://www.douglas-self.com/MUSEUM/POWE ... alveIC.htm (Rotary-Valve Internal Combustion Engine) it was added a line for the PatRoVa rotary valve:

“Another contemporary concept is the PatRoVa rotary valve. Like the Cross design it balances out the forces acting on the rotating valve

I tried a few times to explain to the author that his:

“Like the Cross design it balances out the forces acting on the rotating valve”

is as wrong as it gets, but unsuccessfully.

However it is quite simple: when you have a high or extreme pressure into the combustion chamber, a Cross rotary valve (either with the “reaction bridge” of Cross, or without it) and the bearings whereon the Cross rotary valve abuts, receive a huge force (equal to the area of the window towards the combustion chamber times the pressure) that causes flexing / deformation of the parts, leakage, friction, scuffing etc.

A good characteristic of the Wankel rotary engine for aviation applications is the progressive reduction of the power in case of seizure. Nothing to do with the TBO.

Even with broken or destroyed apex rings, a Wankel rotary can operate at high revs like a turbine.

The above good characteristic of the Wankel rotary is met in the PatRoVa rotary valve, too, wherein there is no case of valve – piston collision. Even in case of severe scuffing, the power of the PatRoVa drops progressively giving the chance for a safe landing.

In comparison, when a poppet valve, or a pushrod, or a rocker arm, or a valve spring, or a cam-lobe of a Rotax airplane engine:

or of a UL390i airplane engine:

fails, a sudden engine stall is possible (valve – piston collision, piston holed, parts into the crankcase, broken connecting rods, holed crankcase etc).

Even if the airplane lands, the engine will need replacement.

On the other hand,

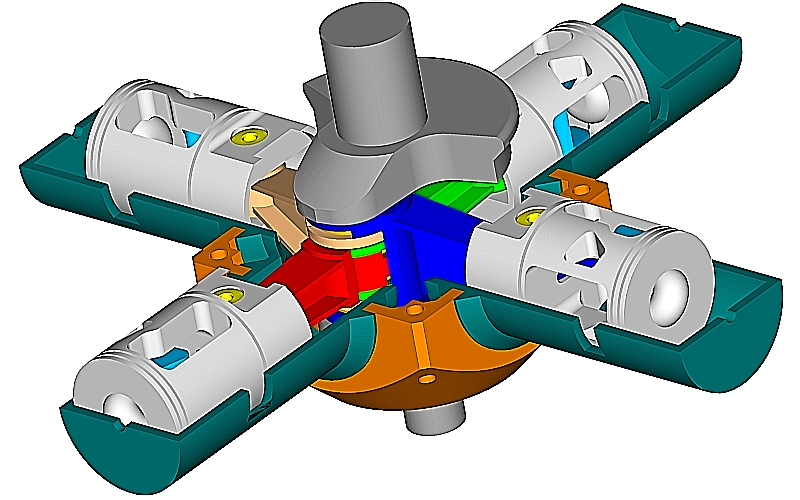

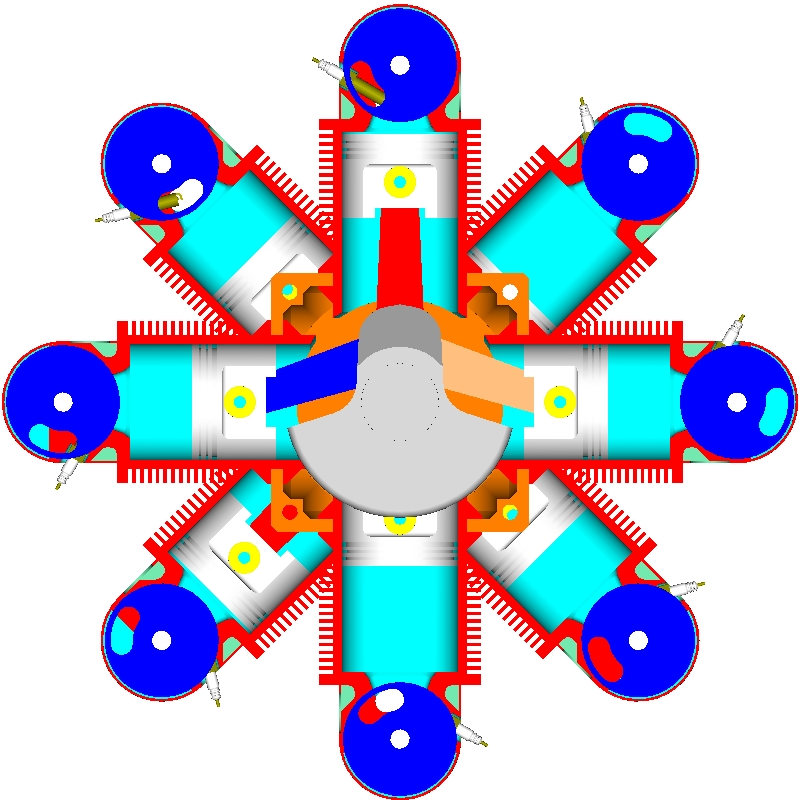

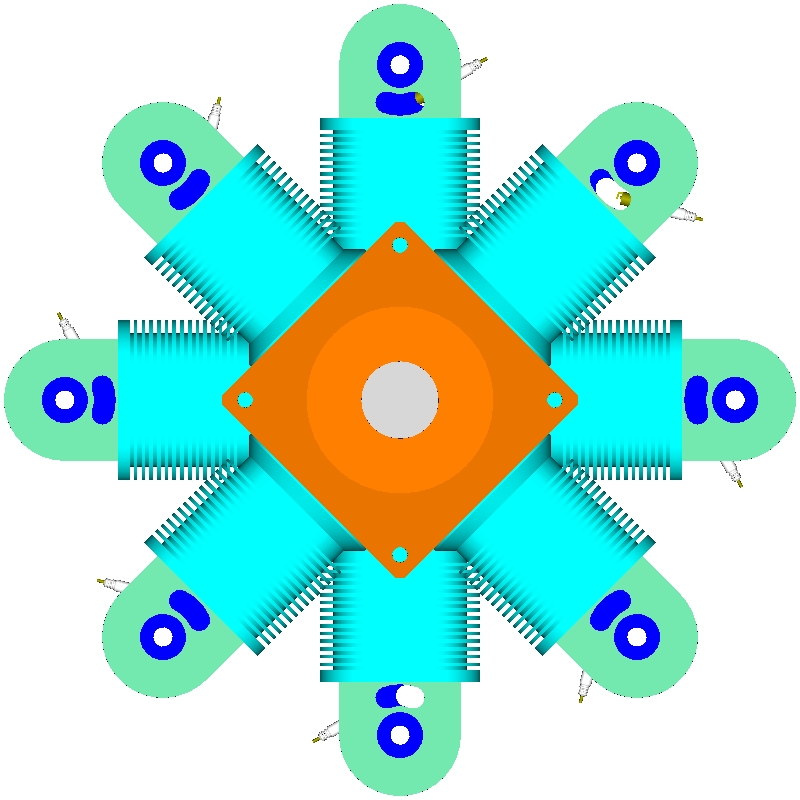

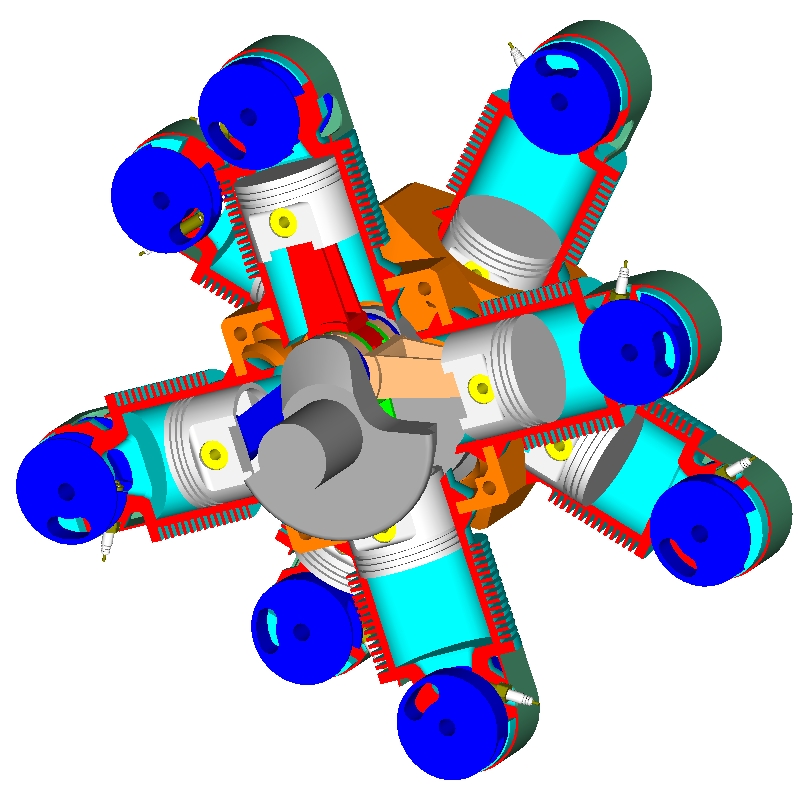

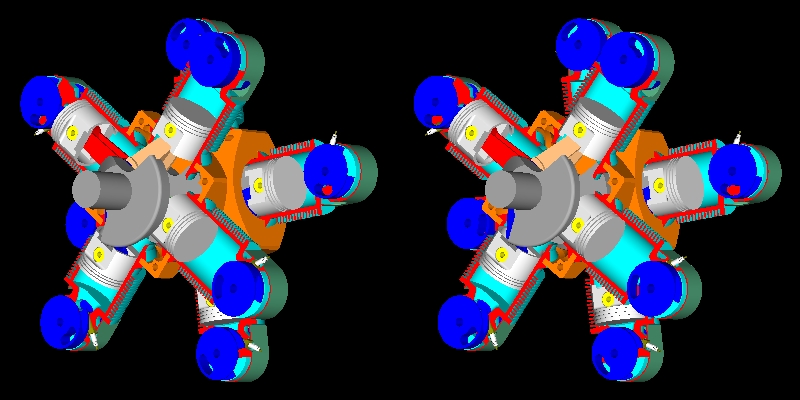

a single-row 2-stoke PatAT Cross-Radial turbocharged Diesel is another approach having its own characteristics / advantages for aviation applications:

However, like the PatRoVa it is unconventional and needs to be put to the tests.

Thanks

Manolis Pattakos