Hello Brian Coat.

Achates Power has similar size with EcoMotors (some 100 millions US dollars , so far) and similarly famous investors (WalMart etc).

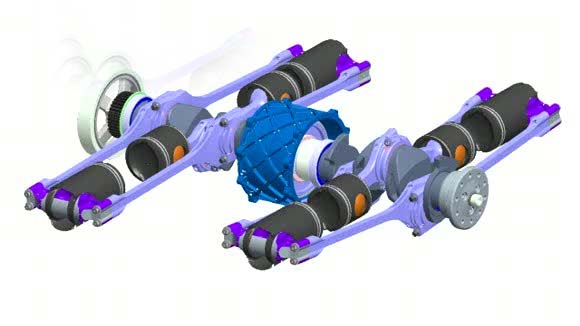

They had several arrangements of Opposed Piston engines, most of them with two counter-rotating crankshafts at the sides of the cylinders, multiple connecting rods (in order to eliminate the thrust loads on the cylinder liner) etc, like:

According the Internet they received some 14 millions from the US Army for an Opposed Piston engine for tanks etc. It is strange that this Opposed Piston for the US Army has the typical design of the old Junkers-Jumo engine.

Hello Muniix

The Ronax 500 has two crankshafts (as, say, the Bimota 500, or the Suzuki RG500), but they say nothing about multi-connecting-rods per piston.

I suppose the overall friction of the Ronax, as compared to a single crankshaft engine, increases.

Talking for the sealing in the Wankel, LiquidPiston and PatWankel rotary engines, here are some interesting, I hope, details:

With their different arrangement of the seals, LiquidPiston creates new “sealing” problems (not existing in the Wankel engine).

According the following drawing (from the patent of LiquidPiston):

there is an immovable “peak” seal, 825, which abuts on the cylindrical working surface 202R of the inner body,

there is also a side seal, 801, in a groove of the inner body, which follows the motion of the inner body.

A LiquidPiston side seal, as the seals of the conventional Wankel, undergoes a substantially variable (in direction and in amplitude) acceleration around the seal and around the cycle.

Here is the inertia force an apex seal of a conventional Wankel applies to the epitrochoidal casing :

(at some angles the inertia vectors outwards, at some other angles it vectors inwards),

and here is the acceleration required in order a point at the top edge (the outmost edge) of the side seal of a LiquidPiston engine to follow the motion imposed by the spinning / orbiting rotor:

and here it is shown, for comparison, the acceleration required in order a point at the innermost edge of the side seal of a LiquidPiston engine to follow the motion imposed by the spinning / orbiting rotor:

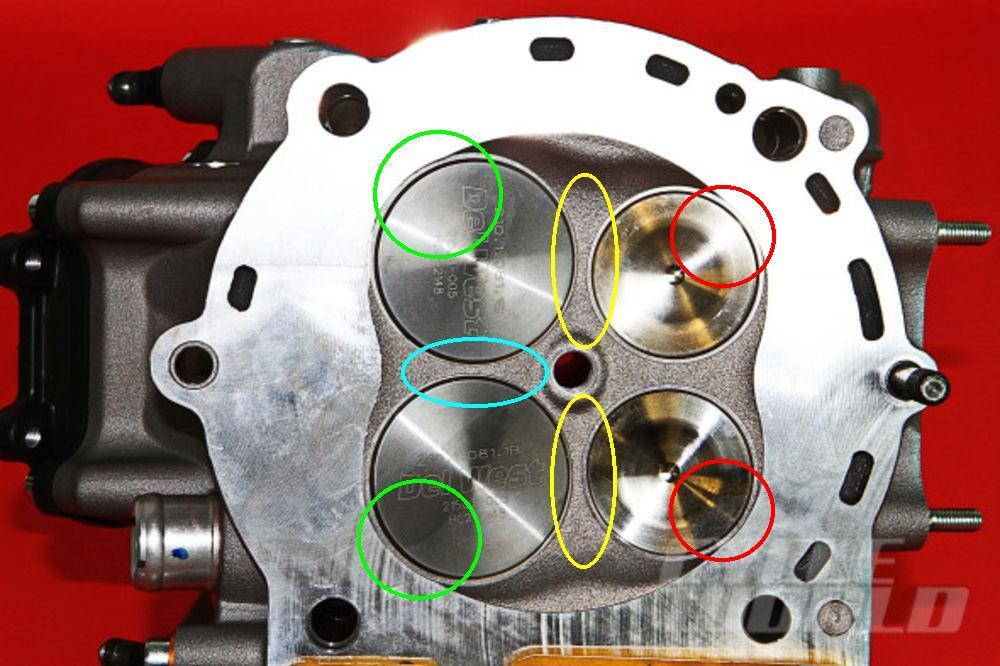

The following drawing helps in understanding the previous plots (the red circles show the path the outmost edge of the side seal follows, the cyan circles show the path the innermost edge of the side seal follows) :

R1 is the "crank-arm" of the eccentric shaft, R2 is the distance of the specific point of the seal from the center of the rotor.

In the LiquidPiston the casing (blue, yellow) is stationary. The rotor (not shown) performs a combined spinning-and-orbiting motion.

The gaps between the apex-seals /corner-seals / side-seals of the Wankel engine are gaps between bodies moving together (they are all inside grooves / holes of the rotor).

In the LiquidPiston, the side seal moves together with the inner body (the rotor), while the rest seals are stationary.

Any clearance of the synchronizing gear-wheels,

and any clearance in the bearings supporting the rotor (the bearing by which the rotor is rotatably mounted on the eccentric shaft and the bearings by which the eccentric shaft is rotatably mounted on the immovable casing),

and any “play” of the side seal inside its groove,

and any flexing of the eccentric shaft (or power shaft) due to inertia and/or combustion loads,

all are added to the required gap between the side seal and the “button seal”.

Note: around each chamber there are four such gaps.

The result is even more gas leakage than in the conventional Wankel.

Now think how the seals are arranged and are working in the PatWankel:

In the PatWankel with the working surface on the inner body, all the seals are inside grooves made on the outer body and perform a pure rotation (during a cycle, the inertia force remains constant in direction and constant in amplitude). Etc.

By the way, without an eccentric shaft, there is no flexing of the eccentric shaft.

Without inertia loads on the bearings, the clearance between the inner and the outer bodies is smaller.

Without eccentric shaft, no balance webs are required.

Thanks

Manolis Pattakos