- Login or Register

No account yet? Sign up

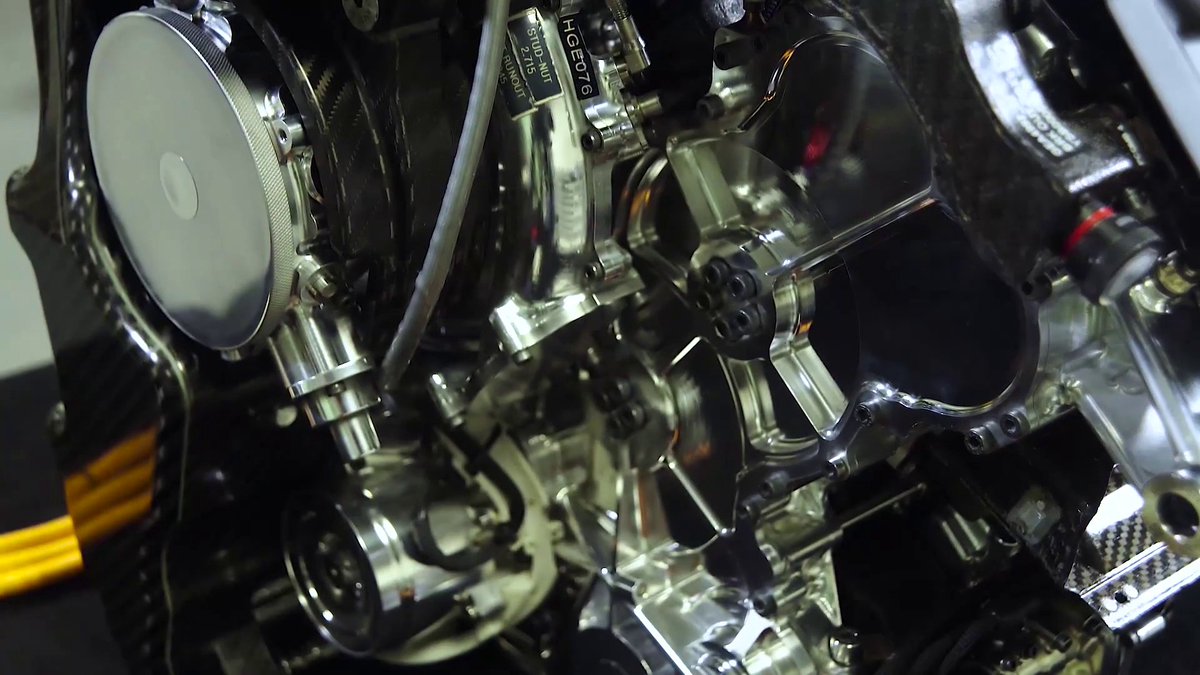

This is interesting. Those different geometry extremes - can you say something about which way their properties would affect the performance of the MGU-h?godlameroso wrote:I'm glad you bring this up, we all should know that there's only 3 real ways to increase electromagnetic induction. The regulations also create a few limitations on those 3 ways. For instance, the total system voltage cannot exceed 1,000 volts, I don't think anyone is using 1,000v yet, so there's scope for development there. We're also limited to 125,000 rpm for the speed of the conductor. We're not limited however by the geometry of the magnetic field, or the geometry of the conductor. So do you design a stubby but very wide MGU-H, or a long skinny one, or somewhere in between? Being that it's unlimited if your MGU-H is powerful and efficient enough at generating electricity, you could deploy indefinitely.ringo wrote:I was referring to the MGUH and it's capacity to harvest at high rotational speeds.

Only 5%, sure, but those five percents are part of a feed-foward loop so some made up "area under the graph" can still be significant.gruntguru wrote:The MGUK and MGUH are both capable of converting over 95% of the applied mechanical power into electricity. The only way to improve the performance of these components is to improve that number. Ask yourself:

"How much improvement might be possible?" (Answer. <5%)

"How much difference will that make?" (Answers <8hp (K) <5hp (H))

Also it's the motor characteristics that need to match as well as possible with your turbine and engine. The geometry will have some influence on the characteristics. The best efficiency point for two very different motors can be the same peak but the motor characteristic over a range of speeds may tell different stories.hurril wrote:Only 5%, sure, but those five percents are part of a feed-foward loop so some made up "area under the graph" can still be significant.gruntguru wrote:The MGUK and MGUH are both capable of converting over 95% of the applied mechanical power into electricity. The only way to improve the performance of these components is to improve that number. Ask yourself:

"How much improvement might be possible?" (Answer. <5%)

"How much difference will that make?" (Answers <8hp (K) <5hp (H))

Most industrial 150kW generators are huge bulky devices, and they only work at much lower RPM ~1,800rpm, the F1 generators are allowed to spin up to 125,000. Getting the generator to be 95% efficient over a wide range of speed is easier than getting the turbine to be that efficient over a wide range of speed. Particularly since the generator is also a motor.ringo wrote:Also it's the motor characteristics that need to match as well as possible with your turbine and engine. The geometry will have some influence on the characteristics. The best efficiency point for two very different motors can be the same peak but the motor characteristic over a range of speeds may tell different stories.hurril wrote:Only 5%, sure, but those five percents are part of a feed-foward loop so some made up "area under the graph" can still be significant.gruntguru wrote:The MGUK and MGUH are both capable of converting over 95% of the applied mechanical power into electricity. The only way to improve the performance of these components is to improve that number. Ask yourself:

"How much improvement might be possible?" (Answer. <5%)

"How much difference will that make?" (Answers <8hp (K) <5hp (H))

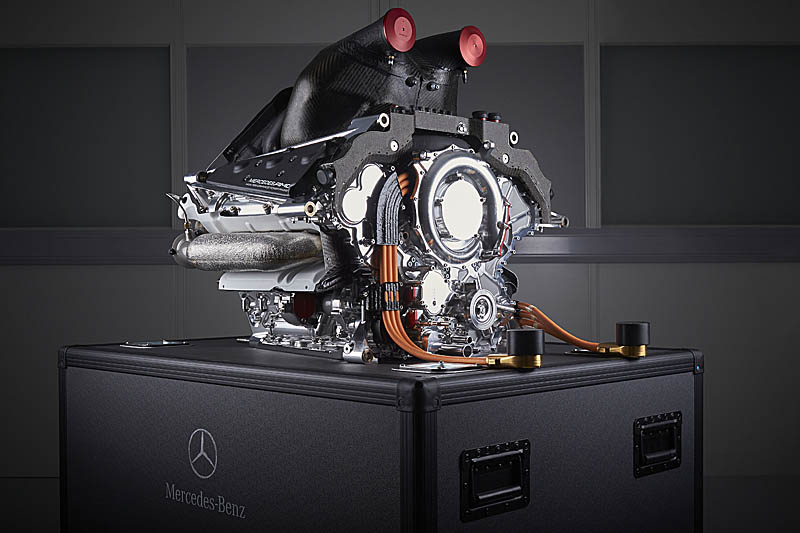

Judging by the following images, it seems to me that it is actually the 2014 PU106A studio images which featured a faux compressor covering:PlatinumZealot wrote:The 2014 compressor is very different - a bit shallower? but wider?

2014

http://www.pitpass.com/images/engines/8 ... edes02.jpg

2015

http://cdn-2.motorsport.com/images/mgl/ ... hybrid.jpg

Thanks for thatLookBackTime wrote:https://twitter.com/andrewbensonf1/stat ... 6847038464