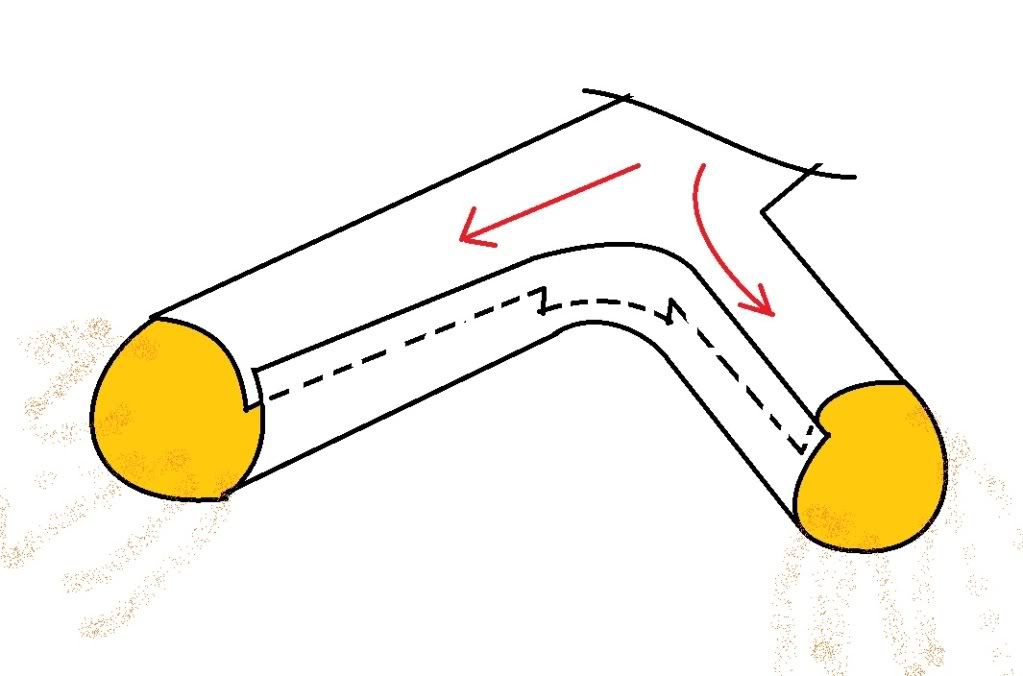

A quick question about the DRS : wouldn't this fail to make the most of the 5cm slot-gap across the full width of the rear wing? If the central section opens up to 5cm, the edges of the flap will not have a gap of 5cm due to being closer to the hinge-point. If the flap edges open up to 5cm, the central section will be illegal due to having a gap greater than 5cm.

Because you cannot make the maximum use of the slot-gap across the full breadth of the wing, it seems to me that this design will not be able to shed as much drag as a conventional design with a straight edged flap. What benefits do you think your design would have over a more conventional layout?

- Login or Register

No account yet? Sign up