Hello.

Theoretically the GDi is a good (the best) solution for the two strokes.

In practice several engine makers tried it without success.

Today there are neither cars, nor motorcycles in Europe’s or USA’s roads powered by 2-stroke engines.

Smaller companies tried it, too.

Orbital’s solution was promising.

The recent Rotax E-TEC (some 200bhp/lt with relatively good emissions and relatively low BSFC) was also promising. It seems it is now abandoned.

In most cases compressed air is used to inject / disperse the fuel after the closing of the exhaust ports.

Besides the emissions and the BSFC, the lubrication and the scuffing resistance are significant issues to be addressed, too.

GDi in a chainsaw sounds too much.

The typical 2-stroke is based on the scavenging / sweeping of the cylinder by the fresh charge.

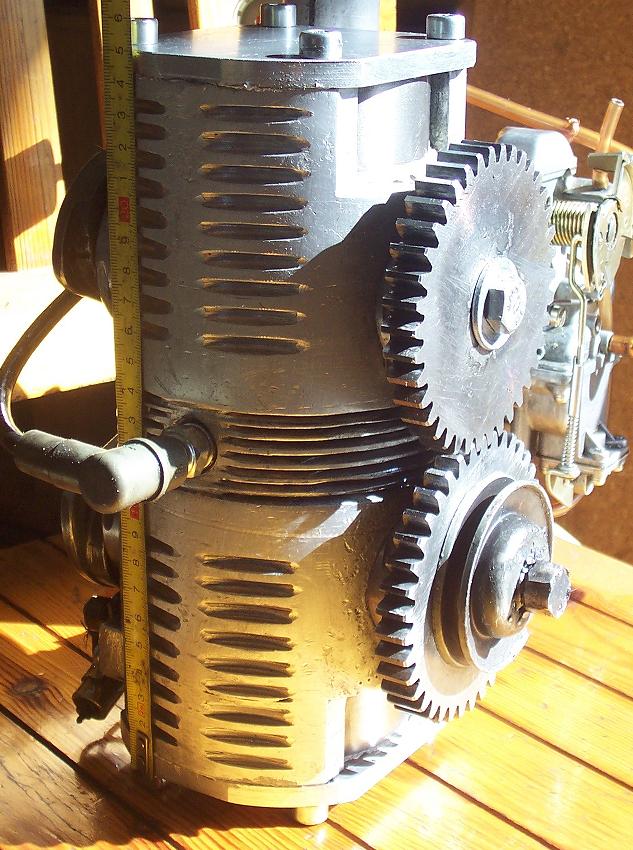

The carbureted PatAT 2-stroke with the zero overlap between the transfer and the exhaust:

is based on a different principle:

Only “after” the closing of the exhaust the transfer opens.

Actually, it does not need to be literally “after”: an adequately short overlap can achieve the same, improving at the same time the “volumetric efficiency.

A part of the compressed, into the crankcase, fresh mixture (primary compression) passes, through the open transfer, into the cylinder (the pressure into the cylinder at the end of the exhaust is about 1 bar).

After the closing of the transfer ports, the gas into the cylinder (which contains a good quantity of exhaust gas / internal EGR) is compressed, burned and expanded.

The downwardly moving piston opens, before the exhaust ports, the transfer ports; but the connecting rod prevents the communication of the cylinder with the crankcase until the end of the exhaust.

Obviously the quantity of fresh charge entering into the cylinder is less than in a typical 2-stroke.

On the other hand, the quantity of unburned fuel escaping to the exhaust has reasons to be less than in the GDi 2-strokes.

Less power, but clean power (and cheap power).

When more power is required, the same engine can easily turn to a conventional 2-stroke:

(more at

http://www.pattakon.com/pattakonPatAT.htm )

It reminds the way the modern car engines are tuned to comply with the emission standards:

At low load and low-medium revs they operate green and fuel-efficient.

When it is required, they can provide a lot of additional (but not green, nor fuel efficient) power. This explains how the real-life tests (fuel consumption) are so different than the official urban and extra-urban figures.

Worth to mention that with a catalyst the problem is not really solved. With a catalyst you can burn the unburned fuel, but you can do nothing about the fuel consumption.

As Brian Coat described it, if for each kWh provided by a pre-2001 2-stroke you gather the unburned fuel emitted by its exhaust and feed with it a good 4-stroke engine, you can produce one more kWh of energy!

The best, by far, solution for the 2-strokes is the compression ignition (Diesel cycle) with direct injection of fuel.

The lean burn (which is a big problem for the spark ignition engines) is the way the Diesels operate: from extremely lean (idling) to almost stoichiometric (at full load).

A good Diesel is a turbocharged Diesel.

For the conventional 2-strokes the closing of the exhaust substantially (some 20 crank degrees) after the transfer spoils the turbocharging.

With the exhaust closing earlier than the transfer, the air from inside the cylinder has not the chance to escape.

See how the above design handles the lubrication:

The crankcase has true 4-stroke lubrication.

The thrust loads are taken by the skirt of the piston (below the oil ring) abuting on the lower cylinder liner, wherein there is plenty of lubricant.

The oil ring (just above the piston ring) never passes over the ports of the cylinder.

When the piston is at the BDC, the lower compression ring abuts on the cylinder liner surface wherein, 180 crankshaft degrees before, it was abutting / oiling the oil ring.

Just follow the animation.

Thanks

Manolis Pattakos