- Login or Register

No account yet? Sign up

Which has very little to do with it. MHPE's superiority is all in the interaction between MGU-H and MGU-K, peak-power is probably about the same for all, but the ability to produce said peak power anywhere around the track is where it's at.Vortex37 wrote:Scarbs says that the key to Mercedes superiority is the layout of the turbo/MGU/compressor.

...

No, I think that wouldn't fly.djos wrote:Just wondering, if Honda did choose the axial compressor route, surely they could argue that as long as they only have a single compression chamber they are within the rules and that the multiple layers of blades is effectively a single stage as a result?

Yes, they do. A turbo fan will typicaly have a fan section of one or two rows, followed by a multi stage low pressure compressor and then a multistage high pressure compressor.djos wrote:Correct me if I'm wrong here, but if you look at a modern high or low bypass jet engine, they essentially have multiple axial compression and expansion chambers aka stages.

It depends on how the lawyers define "single stage" i guess, engineering will come 2nd as usual.wuzak wrote:Things like the double diffuser and the F-duct had loopholes in the wording.

I don't see that is the case here.

They can try!djos wrote:It depends on how the lawyers define "single stage" i guess, engineering will come 2nd as usual.wuzak wrote:Things like the double diffuser and the F-duct had loopholes in the wording.

I don't see that is the case here.

None of the stages of that compressor have a discharge that is both axial and radial, or in other words, a meridional exit angle between 0 and 90 degrees. A multistage compressor having stages with both 0 and 90 degree meridional exit angles does not make a mixed flow compressor.PlatinumZealot wrote:It IS a mixed flow compressor no matter how you look at it. Even your own post suggest that it is.

You are being a bit literal but, Edis you are correct that street car compressor wheels are mixed flow. To the chagrin of some here, I already know that the typical radial compressor is mixed flow(sorry guys). The thing is, the common radial compressor is not called mixed flow these days. For the masses here, I used that photo because I know that is what he meant ( a more pronounced combination of axial then a radial).

I have worked with double sided pump rotors before... Your typical domestic booster pump is double sided. Basically two pump rotors in one if you ask me.. they also deliver high higher pressure ratios. In my post, I said it can be argued to be two compressors. One gas path going in the splits into two different gas paths then joins back again. Heck you can even put two different blade designs on either side if you want. I have no idea what would be the dynamic results of that though. But again in my opinion dual boost can be argued to be two compressors. Why? because say, for example if you stuck two regular compressor wheels on the same shaft facing the same direction instead of back to back, by the wording of the rules it would be no different from a "dual boost" compressor. And yes it would be can be said to be a single stage too... (one step in compression). So it would be up to the FIA to clear this up...

Guys do you realize you have discovered a loop hole!

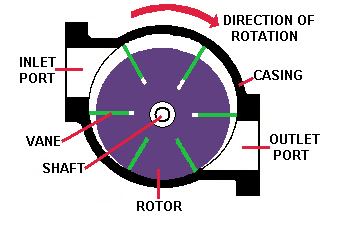

Displacement machines without internal compression are not very efficient as "compressors", and they don't match that well with turbomachines.Charlatan wrote:There is another option however, a volumetric vane-blower, but I'm not certain that it would be feasible for these Rpms?

http://www.austinsevenfriends.com/Bruce ... rawing.jpg

Fast forward to 1:20;

https://www.youtube.com/watch?v=YT5HCpGIxZA

If the stages rotate at the same speed just with differing blade profiles and pitches, then maybe you could just join them with a rotating shroud and claim that it's still one stage as it's all one single rotating assembly? Depends more on how the regs define it rather than what it's actually doing in engineering terms...wuzak wrote:Things like the double diffuser and the F-duct had loopholes in the wording.

I don't see that is the case here.

The point is that a vane-compressor actually has internal compression, if you carefully stydy the images, you might see that.Edis wrote: ...

Displacement machines without internal compression are not very efficient as "compressors", and they don't match that well with turbomachines.

The cutaway of the blade profile creates smaller compression chambers similar to a traditional multistage axial. One stage?denktank wrote:I mean this: https://grabcad.com/library/continuous- ... mpressor-1

Ok. You are talking just abouy the exit of the diffusers being 90 degrees. I understand that.. However. If you look at the gas path from the inlet.. For both compressors the flow still has axial and radial components.Even on the developed mixed flow one in the paper the gas still ends up at 90 though out of the rotating part of the compressor. Very minute details. At the end of the day it to the average man the outside of hondas compressor will still look like the conventional compressor..Edis wrote:None of the stages of that compressor have a discharge that is both axial and radial, or in other words, a meridional exit angle between 0 and 90 degrees. A multistage compressor having stages with both 0 and 90 degree meridional exit angles does not make a mixed flow compressor.PlatinumZealot wrote:It IS a mixed flow compressor no matter how you look at it. Even your own post suggest that it is.

You are being a bit literal but, Edis you are correct that street car compressor wheels are mixed flow. To the chagrin of some here, I already know that the typical radial compressor is mixed flow(sorry guys). The thing is, the common radial compressor is not called mixed flow these days. For the masses here, I used that photo because I know that is what he meant ( a more pronounced combination of axial then a radial).

I have worked with double sided pump rotors before... Your typical domestic booster pump is double sided. Basically two pump rotors in one if you ask me.. they also deliver high higher pressure ratios. In my post, I said it can be argued to be two compressors. One gas path going in the splits into two different gas paths then joins back again. Heck you can even put two different blade designs on either side if you want. I have no idea what would be the dynamic results of that though. But again in my opinion dual boost can be argued to be two compressors. Why? because say, for example if you stuck two regular compressor wheels on the same shaft facing the same direction instead of back to back, by the wording of the rules it would be no different from a "dual boost" compressor. And yes it would be can be said to be a single stage too... (one step in compression). So it would be up to the FIA to clear this up...

Guys do you realize you have discovered a loop hole!

Right side of figure 1, figure 4, 8 and 11 shows a mixed flow compressor.

http://turbolab.tamu.edu/proc/turboproc ... 39-147.pdf

The regular automotive turbocharger uses a radial compressor with a vaneless diffuser.

Displacement machines without internal compression are not very efficient as "compressors", and they don't match that well with turbomachines.Charlatan wrote:There is another option however, a volumetric vane-blower, but I'm not certain that it would be feasible for these Rpms?

http://www.austinsevenfriends.com/Bruce ... rawing.jpg

Fast forward to 1:20;

https://www.youtube.com/watch?v=YT5HCpGIxZA