Well, I'm with riff_raff here, he

knows. I would add a couple of things to the motives you have for wanting low pressure dry sump system. You can skip this part, because most of us know from memory why you use a dry sump, and go directly to the part where I (intend) to answer the question:

Motives we all know

- A dry sump system allows you to create a flatter oil pan and thus an engine with a lower COG. Since F1 cars are very light and their engine represents a large percentage of weight, any gains in engine height are very important. A lower COG is desirable for suspension and chassis designers.

- Keeping most of the oil in a tank outside the crankcase gives you an oil system that provides a constant flow of oil, as opposed to a system where oil is spilling around.

- A dry sump system main difference is that it uses an tall external tank. This tank gives you hydrostatic pressure giving you a more

constant oil pressure. That's probably the main reason to use a dry sump system.

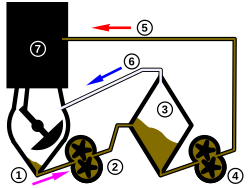

Dry Sump System: the difference with a wet sump is the tank. An F1 system uses another pump at the exit of the tank, this one I took from Formula SAE

- As you imagine from the above image, if you have low pressure in the sump, then

pistons are not working against gas at high pressure when descending.

- Oil is not

mixing with air (air is a poor lubricant) and it's not that exposed to heat and byproducts of combustion that spill into the crankcase area.

- A constant flow system is by far the

most critical part in a durable engine or in its failure and engine duration (failure being obvious) is part of the winning game these days when you are limited in the number of engines and there are penalties for using more.

- A dry sump adds weight and it's not

strictly required, like other parts of the car, because it gives you indirect performance which could be achieved by other means, so it has to be very lightweight. A marginal benefit is that

you do not need to have a "reserve" of oil sloshing around the engine, you're saving the weight of this extra oil.

Thus, you can notice a couple of things, to...

Answer the question, hopefully

1. You can add negative pressure (suction is more... succinct) by increasing pump suction and by

adding oil inlet pressure using a taller tank. In this way you'll get larger suction but

it will be more difficult to "suck the engine dry" in the conduits inside the moving parts that lead to the crankcase pan.

2. You can

eliminate bubbles of air in the oil so they don't add to the gases in the crankcase. You can make the oil spin when it enters the tank and use baffles to keep it spinning all the way to the bottom and use this centrifugal action and a breathing valve to extract air there.

3. You use a

multistage oil pump. These days you have a

5 or 6 stages pump to achieve around 15 cm of Hg.

NASCAR multistage pump

4. You use

two more pumps to suck vapors out of both ends of the valve lifter area right under the intake manifold.

4. You use

several points in the crankcase pan to suck the oil, usually one under each piston or pair of pistons.

Point of oil suction in an F1 engine

Nascar sump showing four different pans for each pair of cylinders

Nascar sump showing four different pans for each pair of cylinders

5. You squirt oil on piston skirts from small nozzles. In this way you extract heat with less oil dripping into the tank and creating oil gas in its fall.

This and the previous image are a courtesy of Steven de Groote at that NICE Formula One site called F1Technical

6. Obviously you don't want air entering the crankcase are from the outside. Thus you use special crankcase end seals with reversed lips.

7. Also obviously you don't use open valve cover breathers.