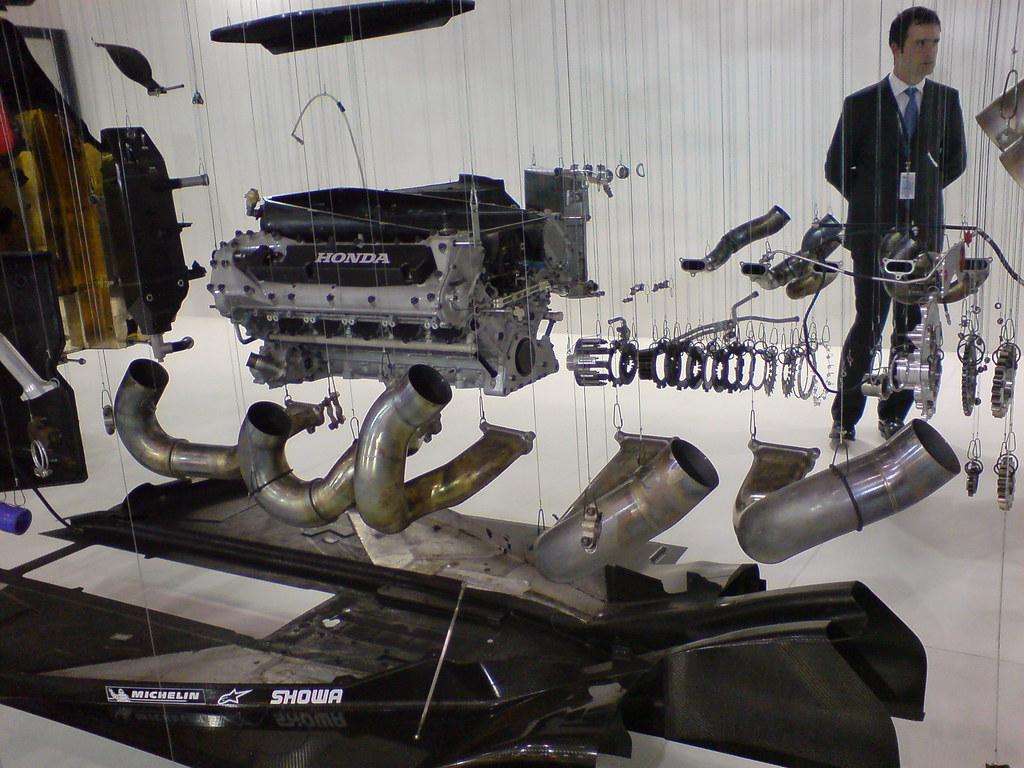

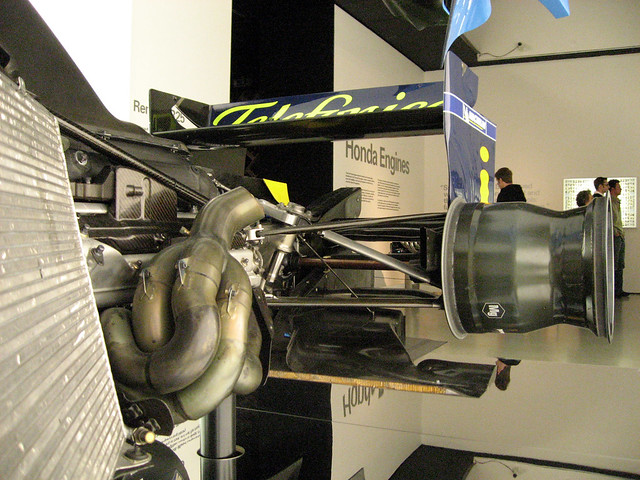

we see those loooong studs poking out of the rear face of the tub...

to me this is creating a means of being able to have enough degree of freedom to get the studs into the engine at all temps and as they are not all the same length you will be able to work one pair at a time ...unfortunatelly the longer ones are those on the top of the engine where you get most of the delta...which could lead to chafing on the lower ones at certain temps.

I wonder if a cicular svivelling of the long

studs at the tub face would be much helpful as the engine supplied mounting is a very long paralell bore ...so you will need a quite a bit of tolerance to be able to align it ,the circular movement not helping at all .It would never work the other ways round (having to start a bolt into a thread in the tub ..).Exp suggesting a dome shaped nut face ,as I understand it,could be on something here,but I have to admit the idea of taking up the expansion by a flexure type mount is a lot more pleasing my little world of thoughts.

The thermal conductivity is not the issue here as well because we are not talking about a possible thermal mismatch in the stud /bore interface but a difference in thermal expansion of the tub (which should be cool ,a lot cooler thank the engine)

and the engine or do i miss something important here? .The big question is will it ,apart from being not nicely engineered ,have an effect of the system behaviour in terms of stiffness over engine temps ?that one might be answered by Dave perhaps ,who might be one of the guys who does a lot of

rig work and I certainly know that some teams experience difficulty to translate Rig findings to the track or fail to reproduce stiffness issues of the chassis on the rig (are these tests done with the engine preheated up to running temps or is the thing tested as cols as it is? A Magnesium bellhousing would make me suspecious when doing rigtesting in cold condition)

-edited post to show more respect to other forum members reasonings - thanks for the little hint ..