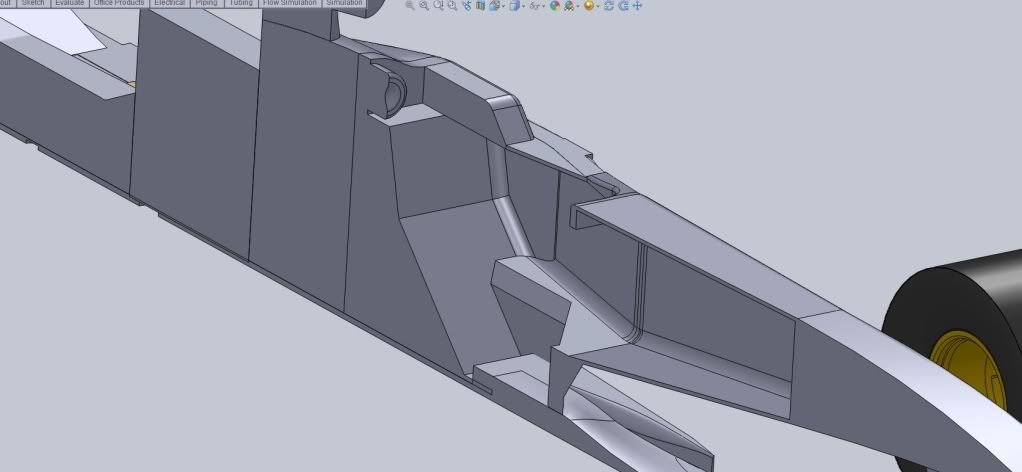

This system lowers wing height and increases AoA much like RBR's flexy nose.

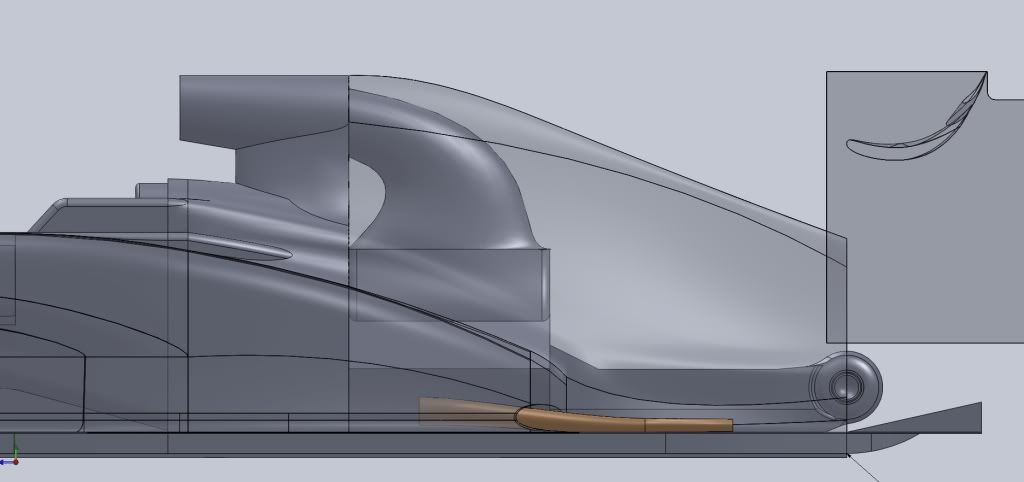

cockpit is rather narrow at the waist. The driver has more room for his upper body and arms though.

cockpit is rather narrow at the waist. The driver has more room for his upper body and arms though.

Well old Juan Pablo was pretty quick!MIKEY_! wrote:Well hey, if the driver fits any tighter packaging is worth it. And vettel's pretty skinny so it's OK

Attention to detail, nice one mate! =D>

I am looking into it. It's still in the concept stage but you can expect something similar to williams.NonNewtonic wrote:Have you started working on the suspensions?

What is this saying?11.3 Brake discs and pads :

11.3.1 No more than one brake disc is permitted on each wheel.

11.3.2 All discs must have a maximum thickness of 28mm and a maximum outside diameter of 278mm.

11.3.3 No more than two brake pads are permitted on each whee

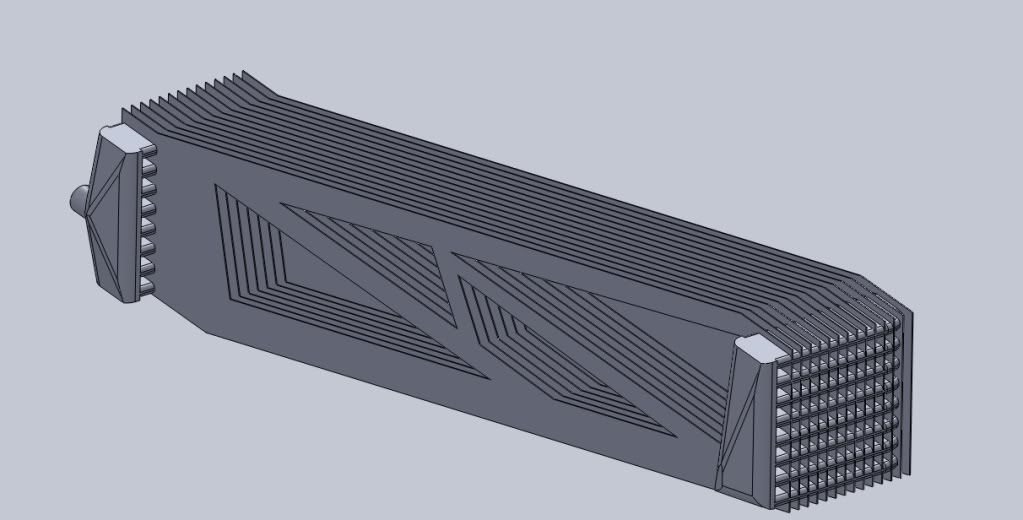

we might see this radiator philosophy in the 2012 cars. I'm gonna try get back to finishing this car and making it's 2012 counterpart.ringo wrote:edit: let me modify the model.

I have come to a conclusion that a standard design is best.

Mine is more thermally efficient, but the absolute temperature drop is not a big for the same surface area.

The plane jane design is the optimum. Mine good for a frontal area compromise and could posibbly work in cool track conditions.

It has some flaws to it, but here it is anyway. It doesnt expose all the surfaces to the lowest temperature like the conventional radiator design. Also the lenght has to be carefully tuned to match the heat rate of the air coming in.

So i'll go back to the drawing board, and have a more conventional design with maybe a slight modification.

Oh yeah i forgot to mention, the cooling fluid in this system is Sodium flouride solution.