Driver equipment

Because of the high speeds that are achieved in Formula One thanks to the technical evolutions during the year, drivers have to be well equipped to handle the cars, and to be able to endure this during 2 hours. We should not forget that no driver can do his job without any mistake, which is why the passive and active safety of the cars need to be of an extreme quality. Very much crashes (especially during the last 4 years) prove that the new constructed vehicles are safer and safer. It is to ensure this safety that many products were developed and enhanced during the history of motorsports.

Seat belts

That is certainly the first option to create a safe position for the driver. The 5-point star seatbelts keep the driver at his place all the time. They protect him from being swung out of the car when it rolls over or flies into a barrier.

Overall and fire protective suits

One of the most important aspects to guarantee driver and equipment safety is to protect them from fire. Costs nor effort are saved to optimize that. The colourful suits that drivers wear are made of lightweight Nomex fibres. These stand 8 seconds of fire exposure, and thereby only causing minor injuries to the driver. The overalls are stitched in a very special way, which allows air cushions between the stitches. As air does guide warmth far less easy than solid material does, this is one of the most important features of an overall. Besides the overall, drivers are protected with a thin Nomex hose, all over their body. It consists of fire protective underwear, pants, a balaclava (image on the left), ... . They also wear Nomex shoes with a hard sole, that gives grip on the pedals, Nomex gloves with suede on the inside for comfort and extra grip on the steering wheel.

One of the most important aspects to guarantee driver and equipment safety is to protect them from fire. Costs nor effort are saved to optimize that. The colourful suits that drivers wear are made of lightweight Nomex fibres. These stand 8 seconds of fire exposure, and thereby only causing minor injuries to the driver. The overalls are stitched in a very special way, which allows air cushions between the stitches. As air does guide warmth far less easy than solid material does, this is one of the most important features of an overall. Besides the overall, drivers are protected with a thin Nomex hose, all over their body. It consists of fire protective underwear, pants, a balaclava (image on the left), ... . They also wear Nomex shoes with a hard sole, that gives grip on the pedals, Nomex gloves with suede on the inside for comfort and extra grip on the steering wheel.

Helmet

The helmet is the only protection for the driver's head. While it is recognition possibility for the spectators and commentators at the circuit, a helmet is the most important part in driver's safety, and even plays an important role in the car's aerodynamics. The helmet area is one of the most turbulent of an F1 car, and it is the aim of helmet designers like Schubert and Bell to decrease that unwanted side-effect. More importantly, when a helmet can be constructed in such a way that it guides more air into the airbox above the driver's head, it may increase engine power, and thus overall speed. Helmet designers should not forget to incorporate breathing holes, helmet ventilation possibilities, space and opening to allow a straw reach the driver's mouth for drinking during the race, and much more...

The helmet is the only protection for the driver's head. While it is recognition possibility for the spectators and commentators at the circuit, a helmet is the most important part in driver's safety, and even plays an important role in the car's aerodynamics. The helmet area is one of the most turbulent of an F1 car, and it is the aim of helmet designers like Schubert and Bell to decrease that unwanted side-effect. More importantly, when a helmet can be constructed in such a way that it guides more air into the airbox above the driver's head, it may increase engine power, and thus overall speed. Helmet designers should not forget to incorporate breathing holes, helmet ventilation possibilities, space and opening to allow a straw reach the driver's mouth for drinking during the race, and much more...

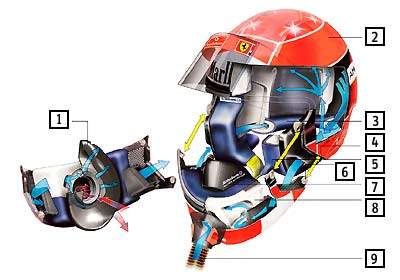

The helmet of each single F1 driver is custom made to fit the driver's needs. After all, the fit decides not only the comfort, but also the level of protection provided. While a common motorcycle helmet is constructed in three layers - padding, inside and outside shell - a Formula 1 helmet has no fewer than 17 layers. The individual components are a jealously guarded secret - the specialists cannot be persuaded to disclose more than the three main substances: carbon fibre for rigidity, fireproof aramide and polyethylene, which is also used in the production of bullet-proof vests and is intended to make the helmet impenetrable. Added to these are aluminium, magnesium and, as a binding agent, epoxy resin. In Formula 1, the saying goes "what is good for a monocoque also makes good clothing". The carbon fibre compounds (CFC) used mean that the helmets are extremely lightweight at about 1.25kg, but can also withstand considerable punishment. The advantages of a light helmet are clear - it serves to reduce the strain on the driver's neck muscles, especially in track sections with high G forces.

During the production of a helmet, 120 carbon fibre mats are glued together. After that, the helmet is off into the autoclave, where the individual layers are bonded to one another and hardened under high pressure and at a constant temperature of 132°C. Parts subject to exceptional loads, such as the underside and the visor cut-out, are additionally reinforced using aluminium and titanium. The interior padding consists of two layers of fireproof Nomex. The ventilation system is designed to allow up to five litres of fresh air to flow into the helmet's interior. A filter cleans the air of the finest motor oil, carbon and brake dust particles. A radio in the chin area provides the means for communication with the pit. Thanks to a tremendous research and development effort, the noise level inside the helmets has been reduced to below 100 decibels.

A good view even in the most difficult situations is vital for the drivers. This is provided by the helmet's 3mm thick visor. It is made from fireproof polycarbonate and its inside is extremely easy on the eye. The tinting adjusts within fractions of a second - similar to some sunglasses, only much faster. For instance, at the tunnel entrance in Monaco, the visor brightens up, darkening again in a split second at the tunnel exit, so that the drivers are not blinded. The visor is furthermore heated to prevent Despite Formula 1 taking a break over winter, the visor is heated.

Before the Fédération Internationale de l'Automobile (FIA) grants its approval for a helmet, it has to pass a number of different crash tests. During the so-called 'penetration test' a 3kg, pointed metal object is dropped from a height of three metres onto the helmet, which must remain unruptured. The helmet's secure fit is also tested. Subjected to a load of 38kg, the chin strap may not stretch by more than 30mm. The visor is bombarded with projectiles travelling at approximately 500km/h. The points of impact may be no deeper than 2.5mm. Last but not least, the helmet is subjected to an 800°C flame for 45 seconds in the fire test. During this time, temperatures inside the helmet may not exceed 70°C.

However, when performance does matter, the driver's comfort should be taken very seriously. As the driver's head is close to the engine, a lot of noise comes with driving a Formula One car. Some helmet design factors try to resolve such things to increase the driver's comfort, and make him able to concentrate better. The following illustration shows all important parts of what may become a standard F1 helmet (this helmet is not yet used by any driver in Formula 1 yet, but has been designed by Schubert for Michael Schumacher). The mouthpiece is similar to that of a fighter pilot and will enable Schumacher to breathe as the helmet will be sealed in order to muffle the noise.:

|

|

Head and Neck Support (HANS) system

Drivers face theoretical deceleration stresses of up to 80 times the force of gravity in an accident. In such a situation, the weight of their head and helmet increases quickly from 7kg to as much as 560kg. HANS would help to absorb this strain, as well as prevent the driver's head from hitting the steering wheel or the front edge of the cockpit. The idea for a neck brace first came about in 1995 following Mika Hakkinen's accident in Adelaide when the Finn's head hit the steering wheel after his car lost control following a tyre deflation and hit the tyre barrier at brewery bend at high speed.

Drivers face theoretical deceleration stresses of up to 80 times the force of gravity in an accident. In such a situation, the weight of their head and helmet increases quickly from 7kg to as much as 560kg. HANS would help to absorb this strain, as well as prevent the driver's head from hitting the steering wheel or the front edge of the cockpit. The idea for a neck brace first came about in 1995 following Mika Hakkinen's accident in Adelaide when the Finn's head hit the steering wheel after his car lost control following a tyre deflation and hit the tyre barrier at brewery bend at high speed.

The system was designed at the University of Michigan. Commissioned by the FIA and in co-operation with its inventor Dr. Robert Hubbard, Mercedes-Benz further developed the 1996 version of the head and neck support. In practice, HANS has initially proven successful in the US NASCAR, ChampCar racing series and in the German Touring Car Masters (DTM).