Isn't air and fluid treated the same? It's just the density that makes the difference?

http://en.wikipedia.org/wiki/Drag_(physics)

- Login or Register

No account yet? Sign up

As dragon fly said both are fluids, and fluid dynamics deal with both liquids and gases, the same principles apply, but theCam wrote:Isn't air and fluid treated the same? It's just the density that makes the difference?

http://en.wikipedia.org/wiki/Drag_(physics)

gato azul wrote:@rjsa

all good mate - no worries

ITA? = Italy? if yes, then no

Yes. I like whinging. You need whingers like me. And I will continue to post in here because as I said, some posts are very interesting. I have a small preview for you guys...Cam wrote:Your're not happy. If you're not happy, leave. Don't whinge and complain about it not being what you want. If you want 'your vision', go start your own forum.n smikle wrote: My faith in f1 technicaL has dropped emensly. ... is just making the site boring for me..

• Not everyone knows other sites exist - hence people link to them

• Quoting journo's and news sources is relevant - even if they're wrong

• Like all mining, you must sift the muck to find the gold

• A wrong post can be valuable if people learn from it

F1 Technical is, for intents, the best online free source for F1 technology, science and discussion on all related things. It's not perfect. But it is a very valuable source of information and 'directory' to external resources.

Take the good with the bad and help move it forward. The world wants solutions, not complaints.

*apologies for the off topic, but really, whingers get me revved.

well said !!amc wrote:

Stalling a wing, in the sense that the boundary layer separates, is not an effective way of reducing drag. It becomes very unpredictable and isn't generally a good thing. In this sense VD, F-ducts and DDRS don't stall their respective wings. Stalling an aircraft wing is not directly to do with speed, slots, blown slots, camber etc. but angle of attack, which increases as the plane slows due to the CoP movement away from the CoG. In fact, DRS doesn't stall the wing either - it just reduces drag and downforce proportionally.

VD, F-duct and DDRS all reduce drag on a wing, and the reason it is mistakenly called 'stalling' is that the amount of downforce produced drops. But that's not really what stalling means. I would like to steer clear of 'stalling' talk as this is a confusing term which can have many different meanings. If an F1 wing were to truly stall at any speed there would be serious problems. It would have a similar effect to Hakkinen's crash at Hockenheim where the rear wing simply broke off. To be avoided.

It may not be effective in an aircraft but it is in a car. Stalling of an aircraft wing has certainly to do with wing profile, speed, ... and not only AoA, that's why large transport aircraft are extremely prone to stalling compared to a propeller fighter. Also as stalling an aircraft wing is a continuous process there is a level of unpredictability (small factors can decide if stalled/not stalled), but the systems we see on cars are binary (if off the wing has a very good flow attachment and if on the flow is well detached). Especially the steepest part of the wing is easy to stall (the F-Ducts went for that area, and the Lotus system reaches maximum wake width there).amc wrote:Stalling a wing, in the sense that the boundary layer separates, is not an effective way of reducing drag. It becomes very unpredictable and isn't generally a good thing. In this sense VD, F-ducts and DDRS don't stall their respective wings. Stalling an aircraft wing is not directly to do with speed, slots, blown slots, camber etc. but angle of attack, which increases as the plane slows due to the CoP movement away from the CoG. In fact, DRS doesn't stall the wing either - it just reduces drag and downforce proportionally.

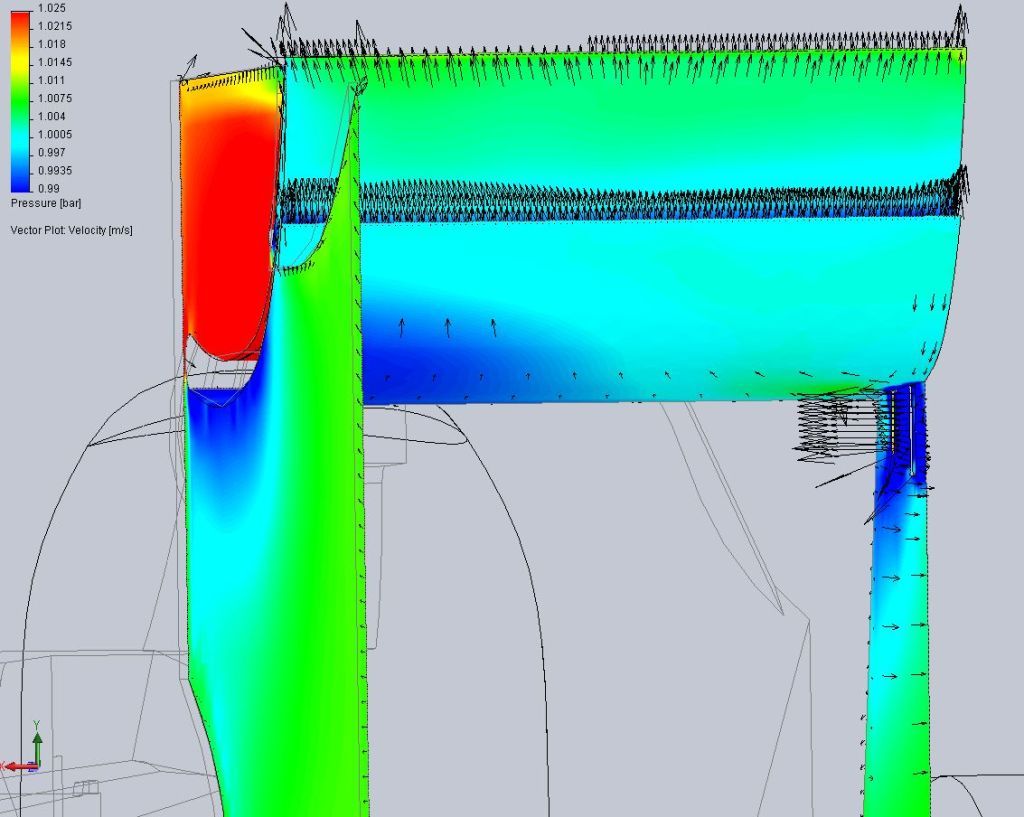

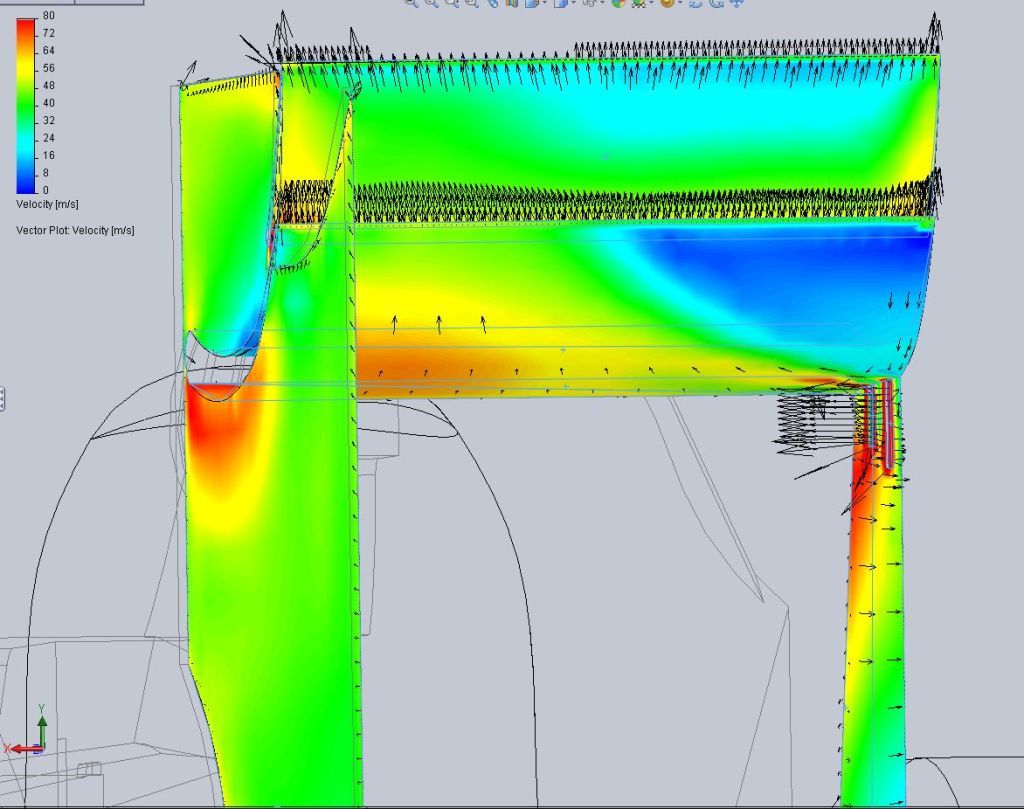

You would be surprised If I told you they are pointing backwards.. about 30 degrees. The low suction peak under the wing sucks the air sideways. This is not the final model though.amc wrote:I don't like to rubbish the theory n_smilke, as there's clearly a lot of work gone into this. However, have you considered directing the flow backwards? I posted a figure earlier that this reduces about 8-12% of the rear wing's total drag, which is a fairly minimal amount, indicating the VD only works on a very small amount of the wing.

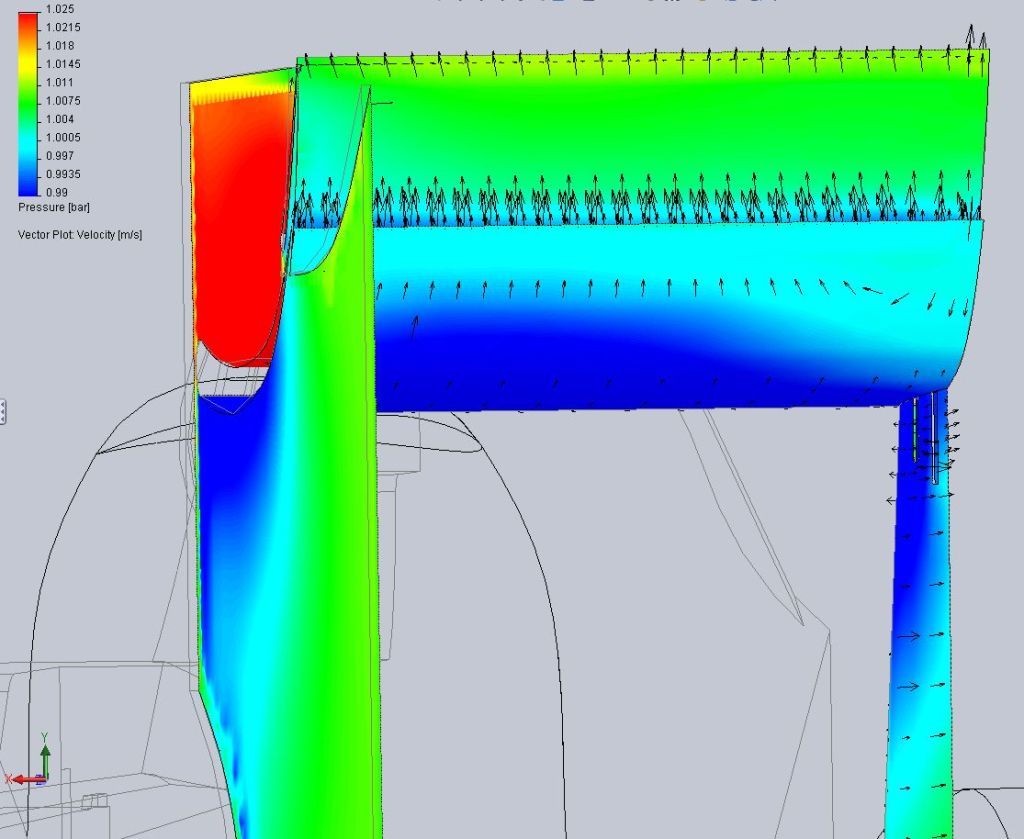

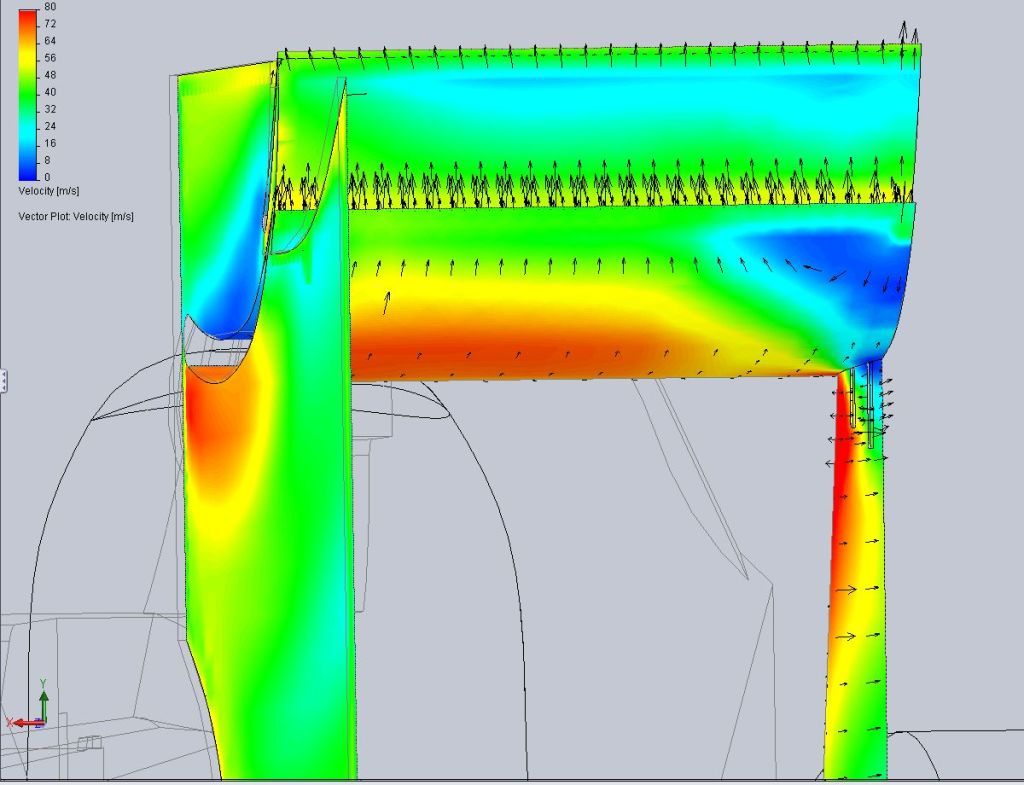

Looking at the CFD, I can tell you why downforce drops and drag doesn't. High pressure air is being pumped straight into a low pressure region necessary for downforce, and with a lower pressure delta there is gong to be less force. Drag isn't reduced much because air is actually pulled back towards the wing to fill the area behind the pylon, which is now vacant of any flow from in front of the wing. Just look at the arrows - they show that air from in front of the wing is moving away from that area, and air behind the wing is being pulled downwards. The low pressure behind the pylon is actually bigger in the third diagram, causing more drag.

Just try pointing the slots backwards and putting flow directly behind the pylon. The low pressure peaks will be untouched, but the arrows that point downwards behind the pylon in the first picture will suddenly point upwards. Faster flow behind the wing means less drag.

Stalling a wing, in the sense that the boundary layer separates, is not an effective way of reducing drag. It becomes very unpredictable and isn't generally a good thing. In this sense VD, F-ducts and DDRS don't stall their respective wings. Stalling an aircraft wing is not directly to do with speed, slots, blown slots, camber etc. but angle of attack, which increases as the plane slows due to the CoP movement away from the CoG. In fact, DRS doesn't stall the wing either - it just reduces drag and downforce proportionally.

VD, F-duct and DDRS all reduce drag on a wing, and the reason it is mistakenly called 'stalling' is that the amount of downforce produced drops. But that's not really what stalling means. I would like to steer clear of 'stalling' talk as this is a confusing term which can have many different meanings. If an F1 wing were to truly stall at any speed there would be serious problems. It would have a similar effect to Hakkinen's crash at Hockenheim where the rear wing simply broke off. To be avoided.

Thanks for the answer n smikle,n smikle wrote: Downforce drops by 13% but the drag doesn't drop significatnly..