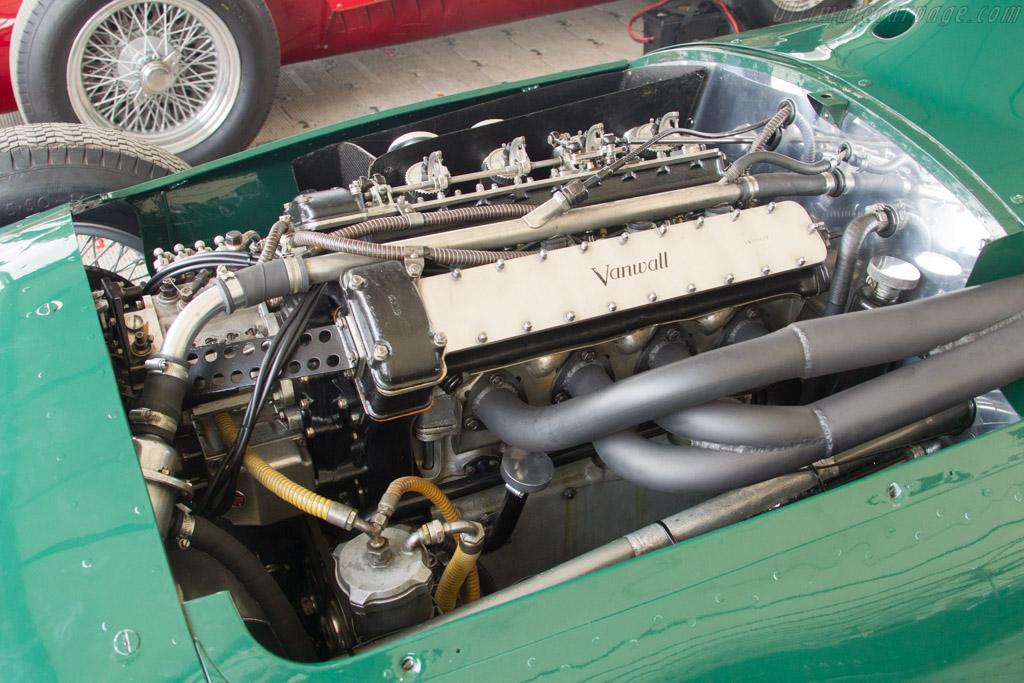

1957 Vanwall V254 2.5-litre four

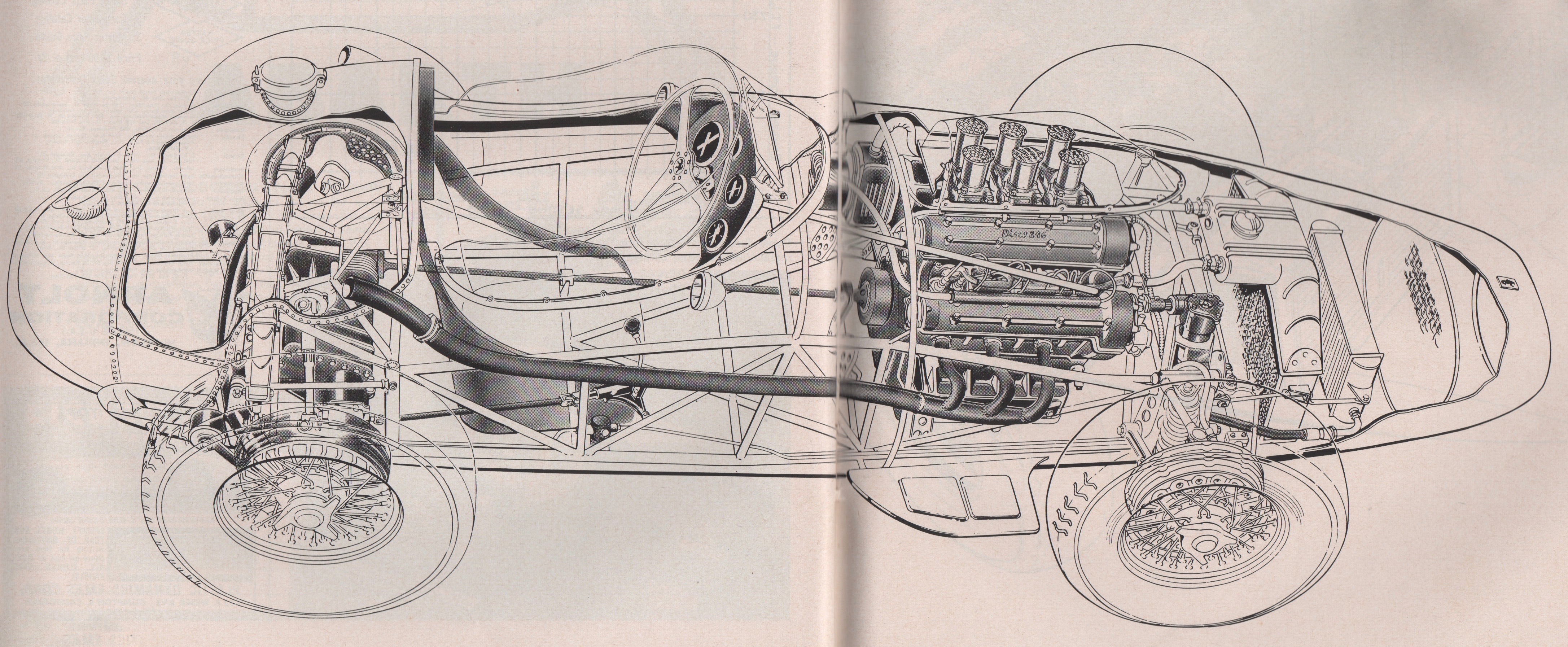

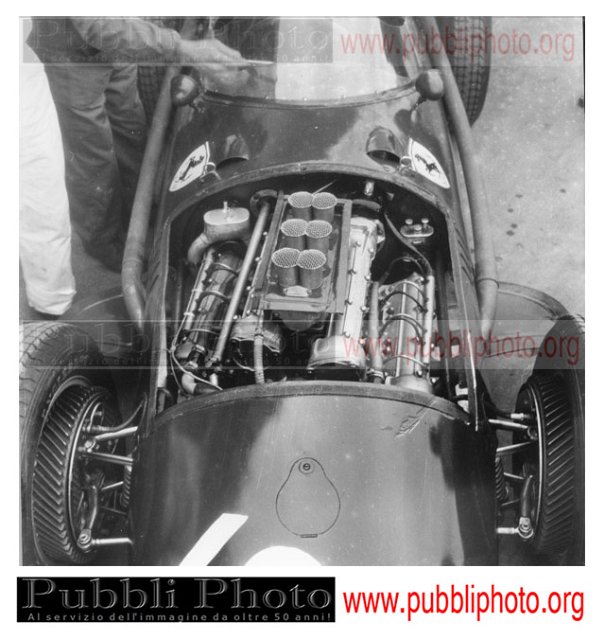

In 1956 the four was installed in a new Vanwall with chassis by Colin Chapman and aerodynamics by Frank Costin, by 1957 it was a winning combination. Vanwall built 7 in all 2.5-litre engines designated V254.

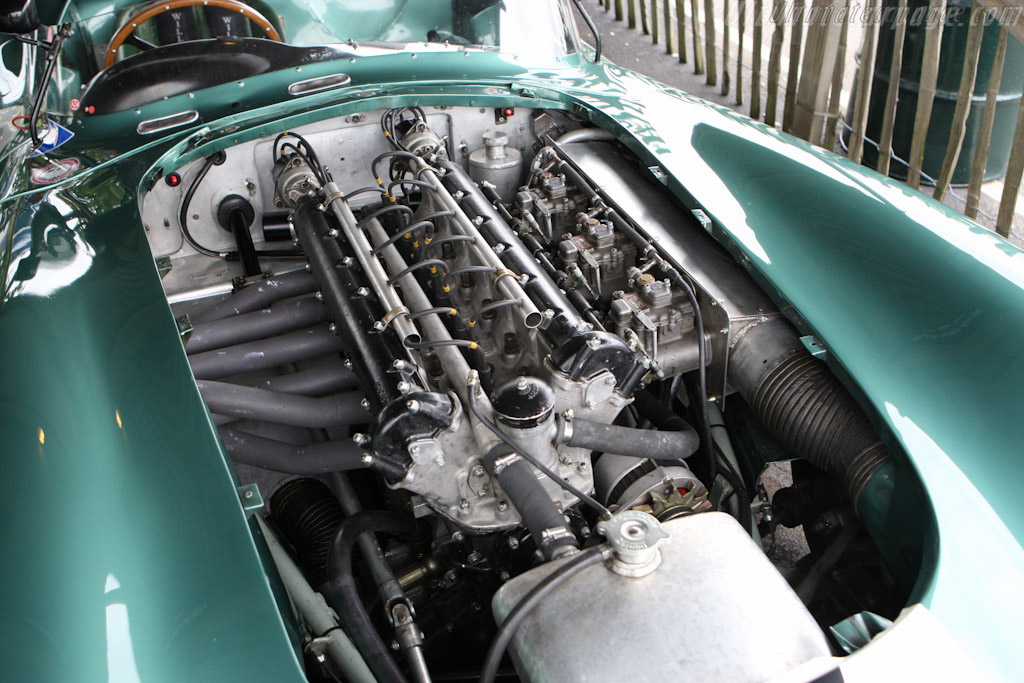

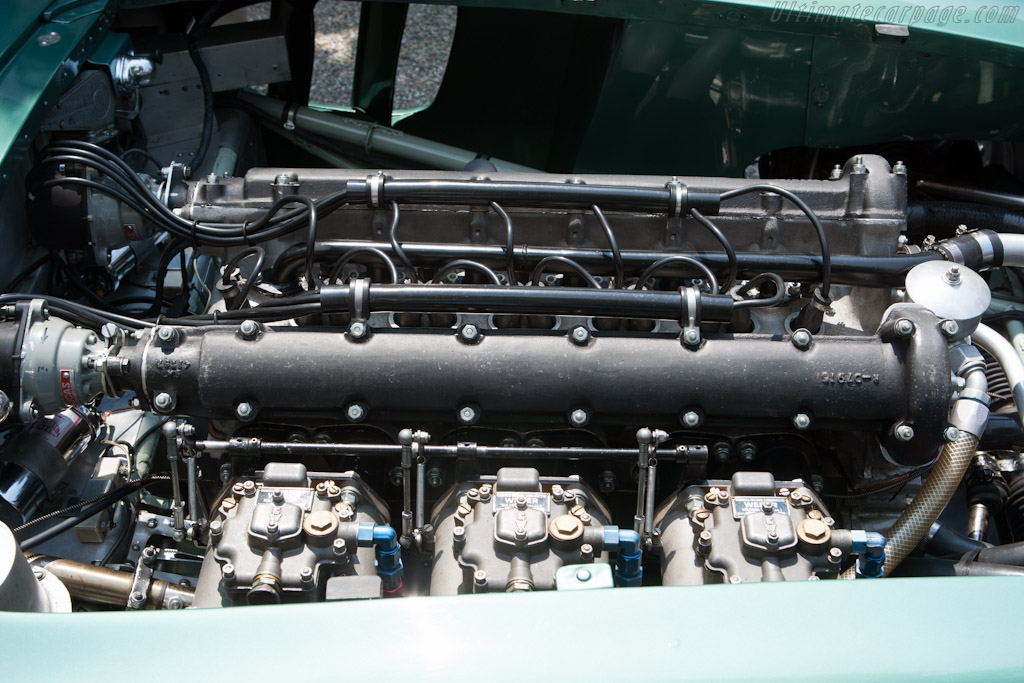

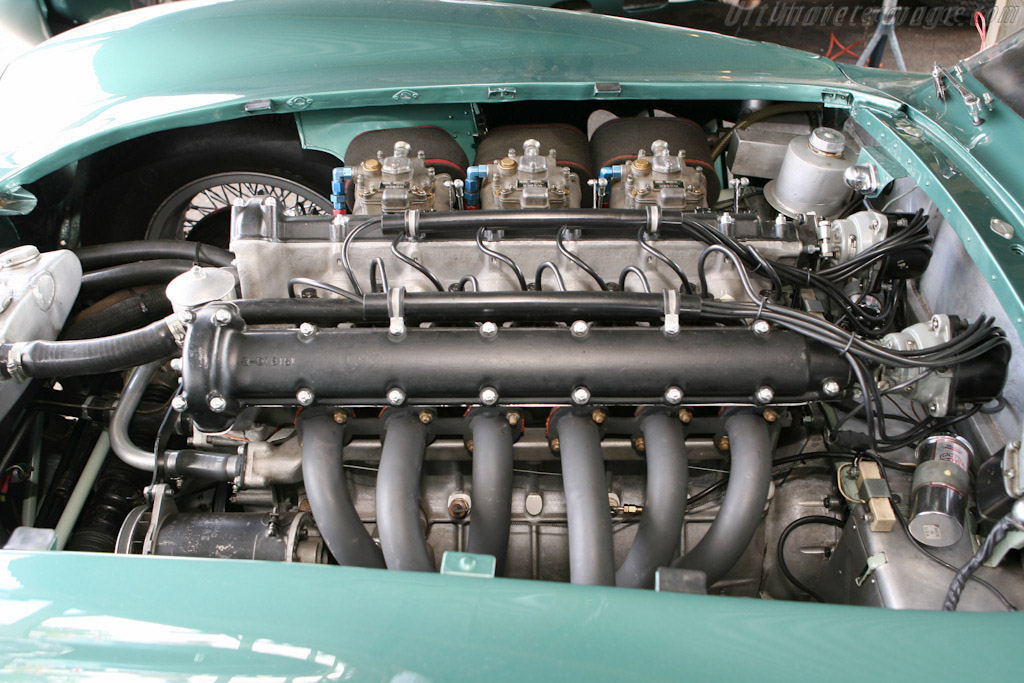

Composed of high-topped, deep-walled crankcase in RR53 aluminum alloy into which individual cast-iron cylinders were deeply spigoted, a water jacket and a shallow cylinder head in RR50 alloy with separate camboxes and exposed valve springs, the whole held together by 10 long high-tensile-steel tie bolts from the head to the main bearing caps.

Nestling inside the tie-bolts and topped and bottomed by rubber sealing rings, the cast RR50 aluminum water jacket steadied and sealed the whole assembly. A structural role was played by the cylinders, which fitted into a radiused countersink in the head. Skirts of the crankcase extended bellow the crankshaft center line. A deep finned sump capped the bottom.

BP oil was used. An EN19 forged 5 main bearing crankshaft was used. EN24 nickel-steel forged con-rods had I-section shanks, were machined all-over and polished. RR59 aluminum alloy piston with full skirt were forged by Hepworth and Grandage, had 2 Dykes compression rings and 1 oil control ring. Cooling oil jets were used to cool the underside of the piston crown.

A compact cylinder head with hot water extracted from it by a manifold between the cams. A water pump mounted low at front of crankcase driven by an extension of the oil pressure pump input shaft. Symmetrically inclined valves at an included angle of 60 degrees and seating on bronze-alloy inserts. Exhaust valve guides were finned and in direct contact with water.

All gears drive to cams were housed in a magnesium casting bolted to block and head. All spur gears ran with ball bearing with 1 idler rotating a single BTH magneto. 2 KLG plugs per cylinder were used. A 3 pinion scavenge pump was used. Each cam rotated in its own case.

Cylindrical hollow tappets sliding in bronze guides. 2 hairpin springs per valve placed out in open air. Bosch fuel injection pump with injector in inlet port just upstream of valve seat injecting at 650psi. Amal carburetor bodies and their control system served as slide throttles.

Specifications:

Cylinders l4.

Bore 96mm.

Stroke 86mm.

Stroke/bore ratio 0.90:1.

Capacity 2490cc.

Compression ratio 12.5:1.

Con-rod length 163.5mm.

Rod/crank radius ratio 3.8:1.

Main bearing journal 70mm.

Rod journal 51mm.

Inlet valve 53mm.

Exhaust valve 45mm.

Inlet opens 70 degrees BTDC.

Inlet closes 90 degrees ABDC.

Exhaust opens 75 degrees BBDC.

Exhaust closes 49 degrees ATDC.

Valves overlap 119 degrees.

Inlet pressure 1Atm.

Engine weight 163kg.

Peak power 285BHP@7200RPM.

Piston speed corrected 21.5m/s.

114.5BHP per litre.

0.57kg per BHP.

- Login or Register

No account yet? Sign up