Sorry took me a while to get back to this one...

pgfpro wrote:I was shock to hear that the Indy Turbo cars had some lag and the drivers were adjusting their driving skills to/for the change.

The BW EFR turbos are a break through in technology and I would of thought their would have been no lag at all.

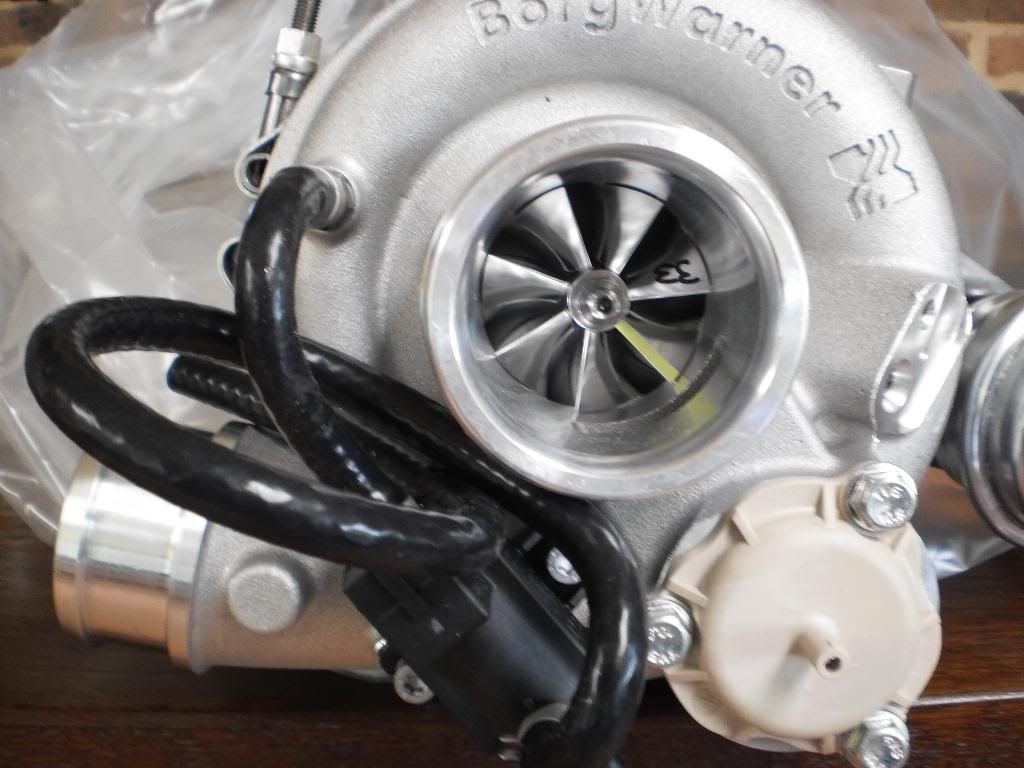

As said I am currently running EFR turbo's, now five of them being the 6258, 6758, 7064, 7163 and a 8374. Whilst they are amazing and light years ahead of competitors, the turbine/compressor shaft will always have mass and as such require a certain amount of energy to get to operating. In the EFR's that threshold is just much lower than it was previously. Where the EFR's shine is you can run a physically smaller and also much lighter unit to reduce the operating threshold to a very low RPM number while also being able to flow greater volume of air. As an example the 6258 spools quicker and earlier than a Garrett GT2860RS, has better transient response but will also flow greater volumes over a larger Garrett GT2871R.

pgfpro wrote:Being a turbo guy myself I always wonder if the lag people think of today's is just the massive vertical torque increase when the turbo kicks in.

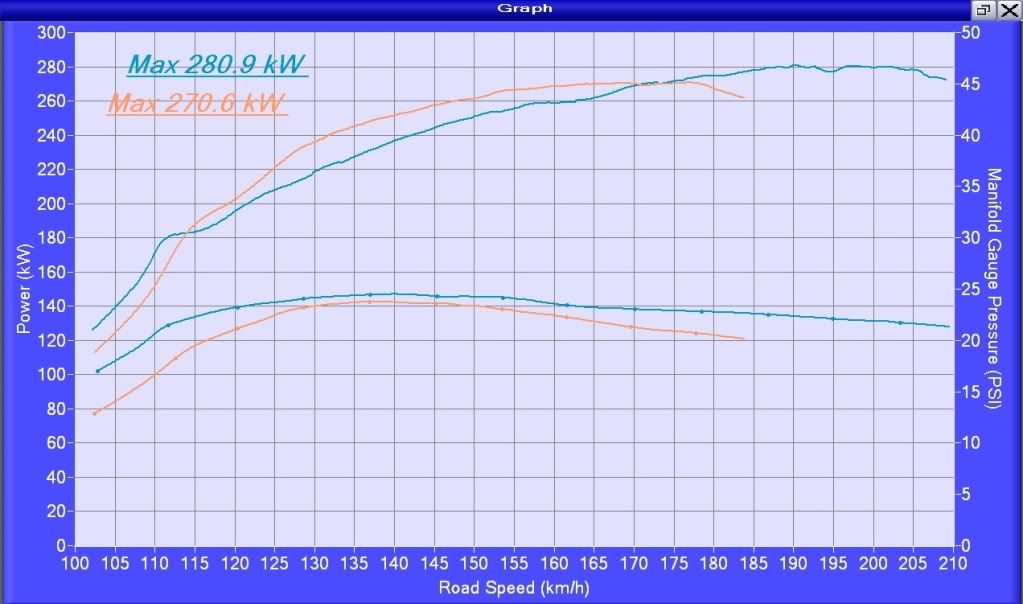

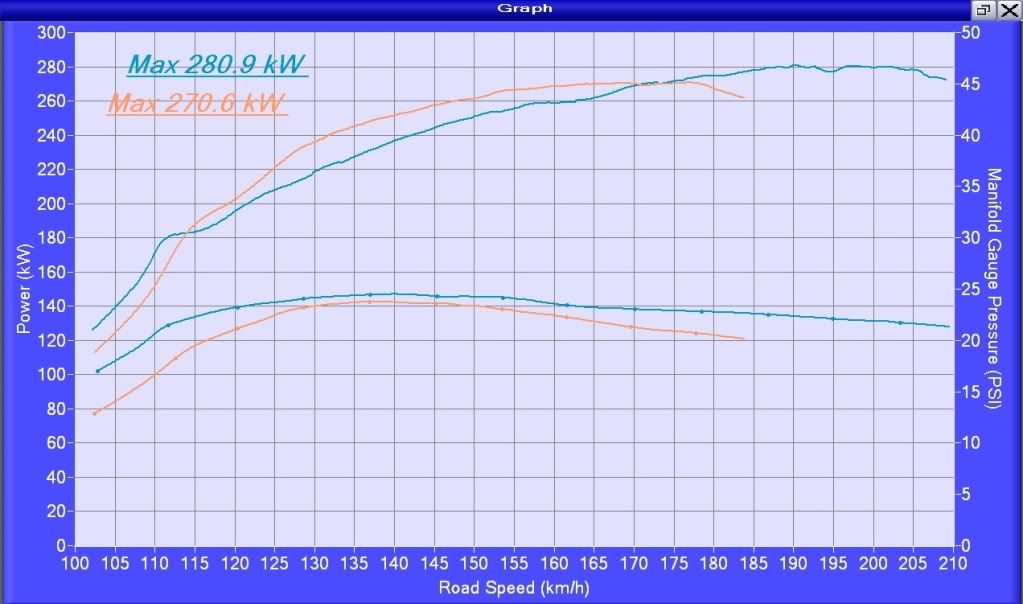

My EFR's have always provided very linear response. No "vertical torque increases". Below is a dyno graph of a 6258 on a 2.0Lt 4 cylinder runnign E85 only with different wategate spring pressures. The softer spring was blowing open so we moved to a stiffer spring.

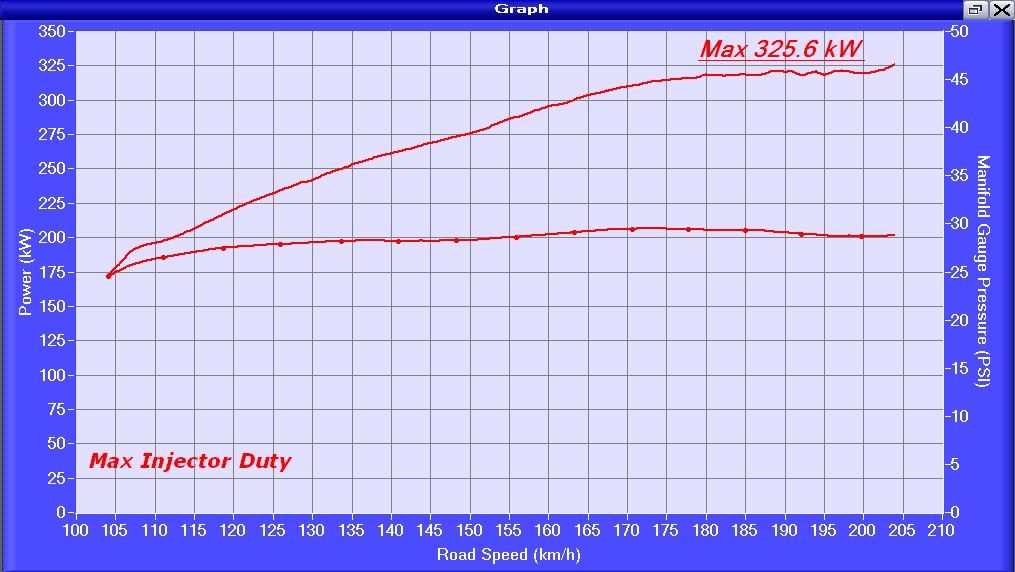

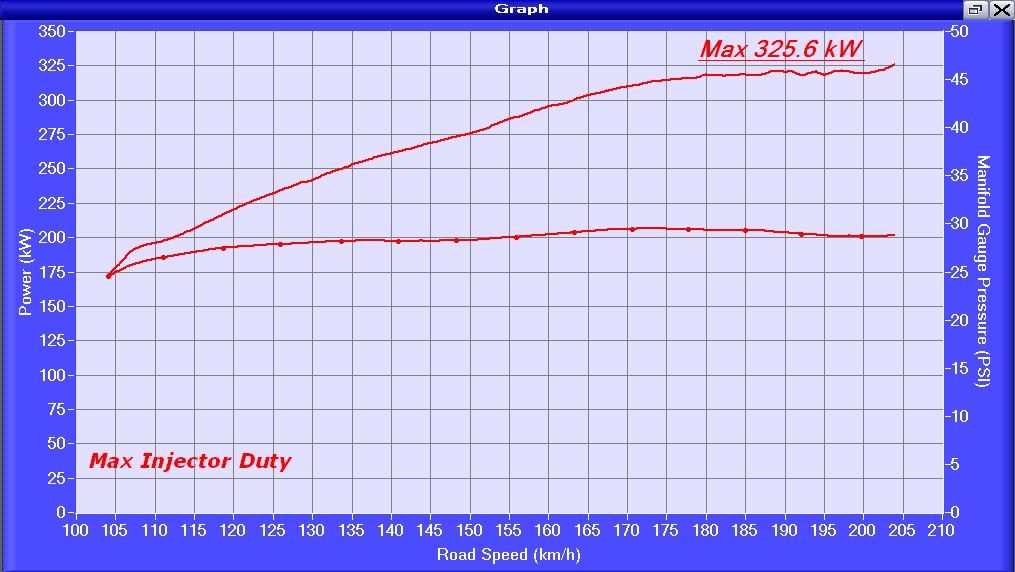

Again, no vertical torque rise. This is the 7163 on the same car. We ran out of injector (1100cc were too small) at 325kw at the front wheels so an estimated 375/380kw or 500hp at the flywheel from a dyno roll down. We are now running larger 2200cc injectors and 3 pumps.

You really only get that sort of all or nothing torque from drag car/dyno queen engines which are all top end power or poor turbo choice for a circuit car. Give me "area under the curve" any day over a big head line number.

pgfpro wrote: I have install a few turbo kits on stock Honda engines and the customer will say wow I thought there wasn't going to be any lag. But what their feeling is just the change of the torque curve that has almost doubled.

So when they blow a charge pipe coupler they realize how much more power and torque has been made from the turbo system and really there isn't any lag it was just slow before.

So with this all said I think the new F1 system will help with the hard hit from from the turbo and the MGU will be able to control this and make the car more drivable.

So considering the the old F1 and soon to come F1 turbos:

The old F1 turbo's were very crude in aerodynamic design, metallurgy and control systems. As a consequence they were typically very "peaky". Early wastegate controls were not from all reports reliable or very tunable. Compressor and turbine aero was poor by todays standards as well. This and the materials used which were typically heavier made the boost threshold and transient response typically poor when all combined.

Modern F1 turbo's will have much more advanced aero designs, metallury and faster more reliable control systems. Couple this with electrical assistance and it may see almost seamless boost delivery across the RPM range as there will be almost no operating range the turbo will not be able to operate in being driven by either the electrical unit or the exhaust gases.

Never approach a Bull from the front, a Horse from the back, or an Idiot from any direction

So when they blow a charge pipe coupler they realize how much more power and torque has been made from the turbo system and really there isn't any lag it was just slow before.