Production engine journal bearing shells have been designed with variable clearances for many years. For ease of production, the main and rod bores are made cylindrical. But the bearing shells are made with a variable wall thickness. I believe Clevite was one of the first companies to do this with their "Delta Wall" bearing design.

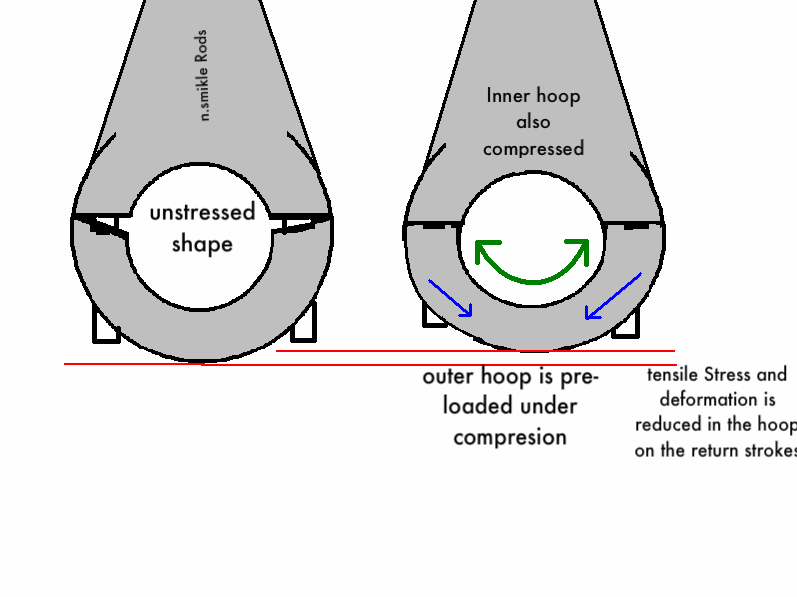

It is not so important to have a perfect circular bearing bore at assembly. What matters is the shape and alignment of the mating bearing and journal surfaces under load. The bearing fluid film only supports loads over a very small area, at very high pressures, on one side of the journal at any given instant. The majority of the remaining bearing circumference is unloaded.

Another important factor is the lambda ratio, which is the ratio between the oil film thickness and relative surface asperity heights. Oil film thickness can be adversely affected by edge load concentrations from misalignments or crank pin bending, inadequate oil viscosity, excessive loads, or excessively rough surfaces.

Finally, having excessively small journal bearing clearances is not a good practice. The oil flows through a journal bearing are based on cooling requirements. The effective flow exit orifice area is determined (in part) by the clearance between the bearing and journal. If the clearance is too small to allow adequate cooling oil flow, the bearing materials will overheat and rapidly fail in fatigue.

Nice set of pictures though. Thanks for posting them.

riff_raff

- Login or Register

No account yet? Sign up