I know this is a W13 thread but they are some of the most interesting articles on floor development thus far and basically confirms Mercedes issue is their 'Aero Concept' which seems to be the underfloor more than the exposed zero sidepod surfaces.

https://www.motorsport.com/f1/news/f1-t ... /10322711/

https://www.formula1.com/en/latest/arti ... JPZqF.html

Based on the level of detail of their floor it seems that Red Bull, more than the others, took into account the exponential nature of pressure/downforce/lift being a function of the Area x Velocity^2 and the variability of all the factors of a car moving at 150+ MPH (change in ride height, bumps, pitch, roll, tire squat, etc.). Their entire floor is designed to soften the transition along that exponential curve. As opposed to Mercedes, with an initial flatter floor and uniform central section that is less accommodating for the sudden rise in pressure/downforce. They were quoted as saying they got too greedy and went for peak downforce but was caught left footed trying to manage it on 18" tires and a loss of their suspension trickery. As the ancient proverb says..... LESS IS MORE.

A few snippets from the F1 article. Keywords throughout the article are transition, variability and uniformity.

As the speed of the car increases it is pulled closer to the ground and the ground effect – which is derived from the air rushing through the small gap of the lowest part of the tunnel to fill the lower-pressure higher area behind – becomes more powerful. As the gap closes to the last few mm, the speed of the airflow – and therefore the amount of downforce – increases exponentially.

The hazard is that it can become so close to the ground that the airflow stalls, triggering porpoising. A higher roof (curved) should make the downforce less height-sensitive, even if its theoretical peak downforce is lower. As the car lowers, this roof would appear to allow for greater expansion of the air and therefore less chance of the gap becoming blocked by excess pressure.

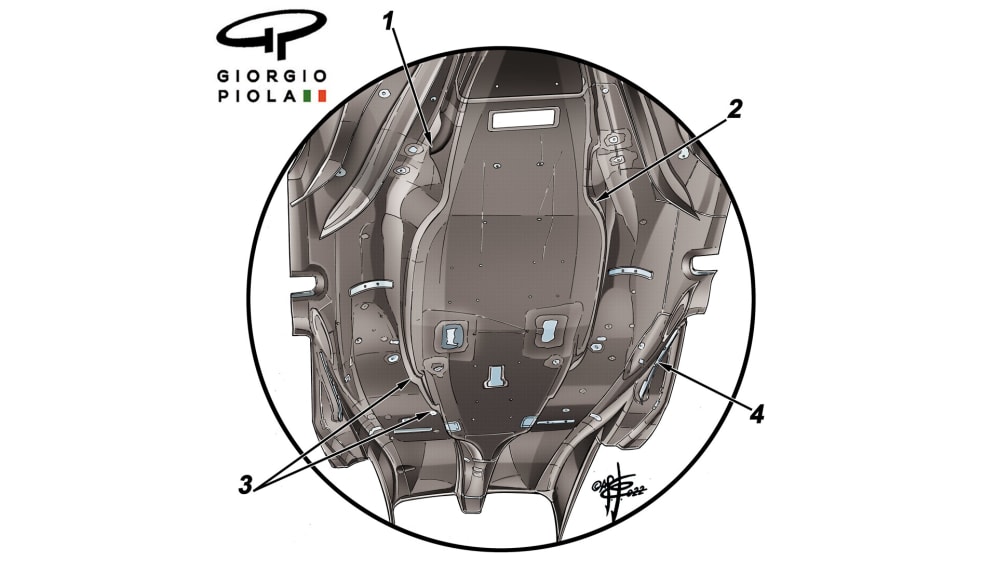

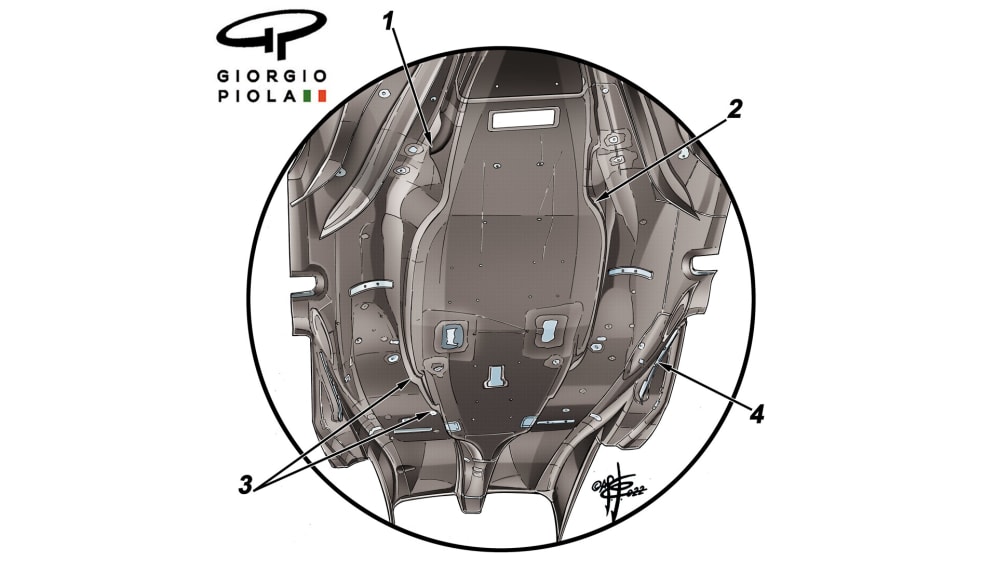

Adrian Newey has pointed out that there are many different airflows beneath the floor and the key is in getting them to work together. The inlet strakes at the front of the floor have variable geometry along their length, probably matched to the shape of the tunnel and therefore helping to equalise the pressure, giving the airflow more energy as it makes its way down the tunnel. A lot of effort looks to have been made to match the lateral and vertical shapes to keep the resultant volume as consistent as possible at different ride heights.

Similarly, the flat central keel is not uniformly pear-shaped as in other cars (see the Ferrari for comparison) and would seem to be shaped in conjunction with the varying height of the tunnel along its length. The tunnel volume available for the air obviously reduces as the ride height lowers. This shaping would make the volume change of the tunnel at various ride heights more uniform along the length. Ferrari's flat central keel is uniformly pear-shaped and less intricate than the Red Bull’s. But even within that general layout, there are several highly distinctive features of the Red Bull floor.

What I am curious about is how much of their "greedy" aero concept is based on the amount of exposed surface area on top with the zero sidepod? Or is it a function of a flatter, less cavernous floor? Can you have that much surface exposure on top combined with a Red Bull type tall and variable tunnel height floor?