It helps becuase it's logical.

Thanks to 747 and dave W for good posts. This is how it's supposed to be done on F1technical.

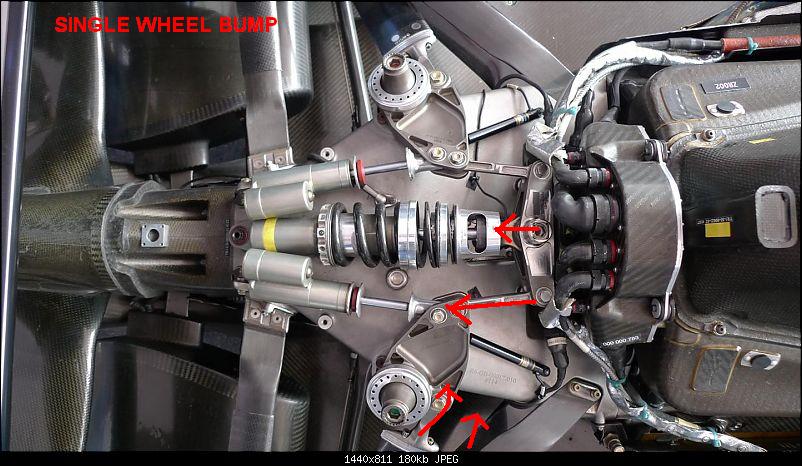

Now, I see where no corner springs will obviously allow the roll stiffness of the axle to be based at zero.

This is all good, but we still have the heave spring in combination with the roll bar. This is not independent tuning, the heave is still effectively behaving like a corner spring. And, i think, it doesn't really change the tuning process, it just eliminates a consideration.

What i think this discussion may lead to is which of the K's , by their nature, would best be taken out for a given situation. Because really and truly instead of eliminating the corner spring, it's stiffness can be as small and close to zero as possible, and the heave or arb can be as stiff or soft, to effect the same stiffness as any other system without one of these elements.

Just to prolonging the convo.

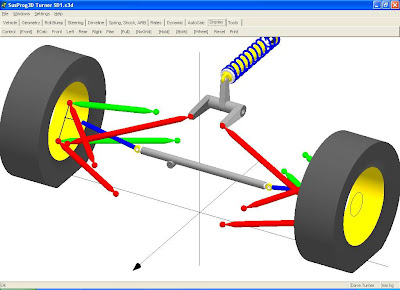

F1 will increase by (Kh + Kb)*Z1, whilst F2 will change by (Kh - Kb)*Z1 - similar in principle to the all springs case, since Kc does not affect the load acting on the connected wheel (for my simple test set-up).

total external Reaction on rear axle in pure heave =

F1 + F2 = (Kh + Kb)*Z1 + (Kh - Kb)*Z1 = 2(Kh)Z1

in pure roll=

F1 + F2 = (Kh + Kb)*Z1 + (Kh - Kb)*(-)Z1 = 2(Kb)Z1

Well clearly for the same displacement direction the ARB wont be activated.

The second equation is interesting becuase depending on the orientation of the car; going over a curb for instance would only involve the ARB. This would be softer than the combination of the 2 Kh and Kb or corner spring. However this only happens with equal and opposite displacement.

The heave spring is only eliminated if it's pushed and pulled with the same force by each side; for a zero compression.

For a mix of roll and heave things get complicated, but the roll bar and heave displacements are inextricably linked.

I see where this is going, and it's quite interesting, but it sounds like a preference thing more than a whole new revolution in suspension linking and design.

It will take some serious analyzing to see the pros and the cons.