2011 could be called the year 0 for the Formula 1. It had been years that the championship of the world had so many regulatory changes .. One of the most interesting changes at the technical level is the KERS (already used in the F1 world championship in 2009).

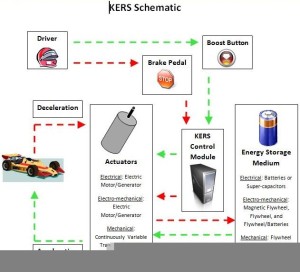

KERS (Kinetic Energy Recovery System, or "kinetic energy recovery system), is a device that allows, if necessary, an increase of 60 kW of power, equal to 80 hp for 6.7 seconds. The FIA has introduced this system / mechanism (not required) to facilitate overtaking and then increase the show ..

All teams except Williams, have opted for the KERS electric Grove, for the electro - mechanical. Both systems can store power for a maximum of 400 kJ per lap. The stored energy for both systems, even when braking takes place, is even to be more precise, since the stage of gas release.

When talking about KERS is best not to speak of "energy recovery" but simply "processing energy"

Now look, specifically, the operation of electric KERS.

KERS Electric aims to produce electricity by a motorcycle - electric generator (MGU Motor Generator Unit). This device can be connected directly to the transmission shaft parallel to the exchange or through a cascade of gear reducers. The latter solution is very complex because all the teams that use the electric KERS have turned to the positioning of the MGU in front of the traditional combustion engine. The conversion of kinetic energy into electricity occurs when the driver operates the brake pedal to certain pressures, previously calibrated and operated by the ECU.

When the car stops (or release the gas), in fact, the moto-alternator, through a system of hydraulic clutches, it should be taken in the crankshaft. Under normal conditions, the motion - alternator have to be disconnected, otherwise there would be a loss of power, as well as producing harmful friction.

During braking, so the dynamo acts as MGU (such as the alternator of the car as standard). The energy produced is stored in lithium batteries, the combination of which is defined HVB (Hight Voltage Battery Pack).

When the pilot will require the extra power, just press a button on the steering wheel. In this phase, the MGU is no longer acting as alternatives but as a driver - electric, going back into socket on the crankshaft or transmission and returning the energy stored earlier. In this phase, electrical energy is converted into mechanical energy.

The pilot will use the extra power, at once per revolution (80 Cv continued for 6.67 s), or modulate it and divided several times as it sees fit. The "boost" is also operated during the start, but not immediately turning off the red light. In fact, the system can load and release energy at speeds above 100 km / h.

KERS Electric, according to unofficial sources, works at 400 V and 700 - 800 A and weighs all-around 25 -30 kg This weight, it will add weight to the minimum required by regulation (605 kg). Therefore, technicians, must ensure, before the stay KERS to lighten the car and explore a new weight distribution.

The idea of KERS is certainly interesting, but not in the 2009 season was a huge success. The strong regulatory limits have the potential to partially castrated, facilitating the task of those teams that have focused sull'esasperazione aerodynamics, ricunciando immediately to the development of KERS, since the use was optional in 2009. It is no coincidence that Brawn and Red Bull Racing, who have fought for the world title, has never used energy recovery, while Ferrari, McLaren, Renault and BMW have invested significant funds. From the first track tests reveal any problems of reliability and security that had led the Toyota not to venture on this terrain, since the Nissan was that the market was leading the series hybrid cars and did not want a problem F.1 could reflect negatively on sales. In the first test of a BMW mechanic was struck by a burst of eddy currents. and so, mechanics, technicians and road marshals were equipped with special insulating gloves to avoid the violent eddy currents. The trouble with security, in fact, had been cleverly solved, but the nearly 40 kg at the beginning that the system weighed heavily conditioned performance, which were not offset dall'overboost power available in a limited time too.

E 'right to ask questions and go on KERS understand what were the problems to be solved.

The system, as mentioned earlier, was composed of three elements: the motor-generator that functioned as an alternator and electric motor, lithium batteries and electronic control unit. The motor generator unit (MGU), during deceleration, worked as a generator, producing electricity that was stored in batteries, waiting for the driver to download the extra power during acceleration. In this case, the MGU, powered by batteries, operated by an electric motor, in sync with the combustion, contributing to the car's performance. There was also a special unit that handles all these steps.

Williams, however, had experienced an electro-mechanical system instead of the motor generator. The Williams system, the lighter of the electrical system, instead of the lithium battery has a carbon-fiber flywheel which rotates in a crankcase vacuum to reduce friction. The fly, which works usually coupled to an electric motor, is expected to reach speeds well in excess of 40.000/50.000 rpm, or even close to 100 rpm. In this system, the stored energy during deceleration is stored in the form of kinetic energy. In practice, this device, on the principle of the old machines toy "friction" (those that are charged by spinning the wheel and then release them and make them run on the floor of the house) inside which there was flying (rather heavy), which Once activated, released its kinetic energy to the transmission shaft connected to the wheels.

The engineers had decided to install it between the engine and the body, in a critical area of the car, surrounded by the fuel tank. KERS weighed around 35-40 kg, a mass that was not added to the minimum weight of F1 (this weight but was added by the Technical Regulations of 2011). The technicians who worked on it, you have less ballast to help find the perfect car balance with a proper weight distribution. The plant not only had the handicap of weight, but also that of the volume: the mass of the KERS car has heavily influenced the design of the car. Ferrari's engineers are able to put all the STTA system in a suitcase the size of a 48 hours, and time are STTA made important steps in the miniaturization of parts. The first MGU weighed about 6 / 7 Kg: permanent magnet synchronous motor turning speed operation of the V8 petrol: 18,000 rpm. Doubling the speed to 36,000 rpm, the mass had fallen by one third, making it necessary, however, in coupling a clutch between the two power units (electric and gasoline).

Ferrari and McLaren have benefited from the KERS at the start: these cars have often won the position at the start thanks all'overboost (worked over 100 km / h).

The difficulties that had emerged during the season was the charging of lithium batteries and their cooling: in fact, to ensure proper cooling, it had come to a real cooling system. GP in the hottest of the difficulty was to recover all the energy needed to have a sufficient boost, as it varied greatly depending on the shape of the track and the number of detached. The rule, in fact, limited the use of acceleration energy of 400 kJ, but did not prevent a greater storage batterie.Siccome in the performance of the system did not exceed 50% for 400Kj used, it was necessary to dispose of more than 800. Each time they failed to reach the threshold, the more power for 6.6 s, there was 80 hp, but less and less. The Ferrari seems to have never suffered from this problem but the McLaren is, just because the batteries were working in a narrow temperature range. If the battery was too cold not broke, but had too high an internal resistance, so it was not efficient, but it was too hot lost in performance lap after lap. The ideal was to make it work in a range between 75 and 85 degrees, while the electric motor and the electronic control unit could easily withstand the temperatures of the engine, close to 120 ° C. In mass production there were no batteries to meet the demands of F1 and years of research in the Circus will certainly contribute to the development of new batteries for the market. And the KERS could become a useful tool not only to increase performance but also in reducing fuel consumption.