Well, for a start, the student made the following statement:

At the time of the project (end of 2009) the new FIA's regulations for the upcoming racing season (2010) was not yet all disclosed and revealed (e.g. many technical drawing where missing on the regulation itself) so I had to work really hard also in the Regulation understanding & interpretation process)

The geometry as not been optimized due to a lack of time (as it can be seen in the 2d graphics results the flap stalls)..a better design should be evaluated.

So, he didn't know the regs properly and he admits that the geometry needs further work.

Looking at the chosen design:

I would suggest that there is an indication of an outward flow endplate there. I also note how the aerofoil separation distances are far from representative of a real front wing. Also, as noted elsewhere in the thread, the lack of a rotating wheel behind the wing removes a major factor in the flow of air around the wing.

This piece of work definitely can not be used as a way of justifying a non-outward flow endplate. It's just too basic a piece of work (with all due respect to the student who has otherwise obviously worked hard on his thesis and I applaud him for that).

Back to the original issue - the current wide front wing suffers from the front tyre interupting the free flow from approx. 30-40% of the active downforce producing surface of the wing. Thus any wing / wheel interaction will endeavour to do 3 things:

1. reduce the lift experienced by the tyre as this is working against the downforce and reduces the net grip available

2. reduce the drag caused by the tyre

3. increase the extraction of air from below the front wing (sometimes called scavenging the flow).

The flow coming off the front wing can go three ways: outside the tyre, over the tyre, inside the tyre.

We have seen, in the paper quoted by bhallg2k, that flow over the front tyre increases front tyre lift and drag. This is obviously not a good choice.

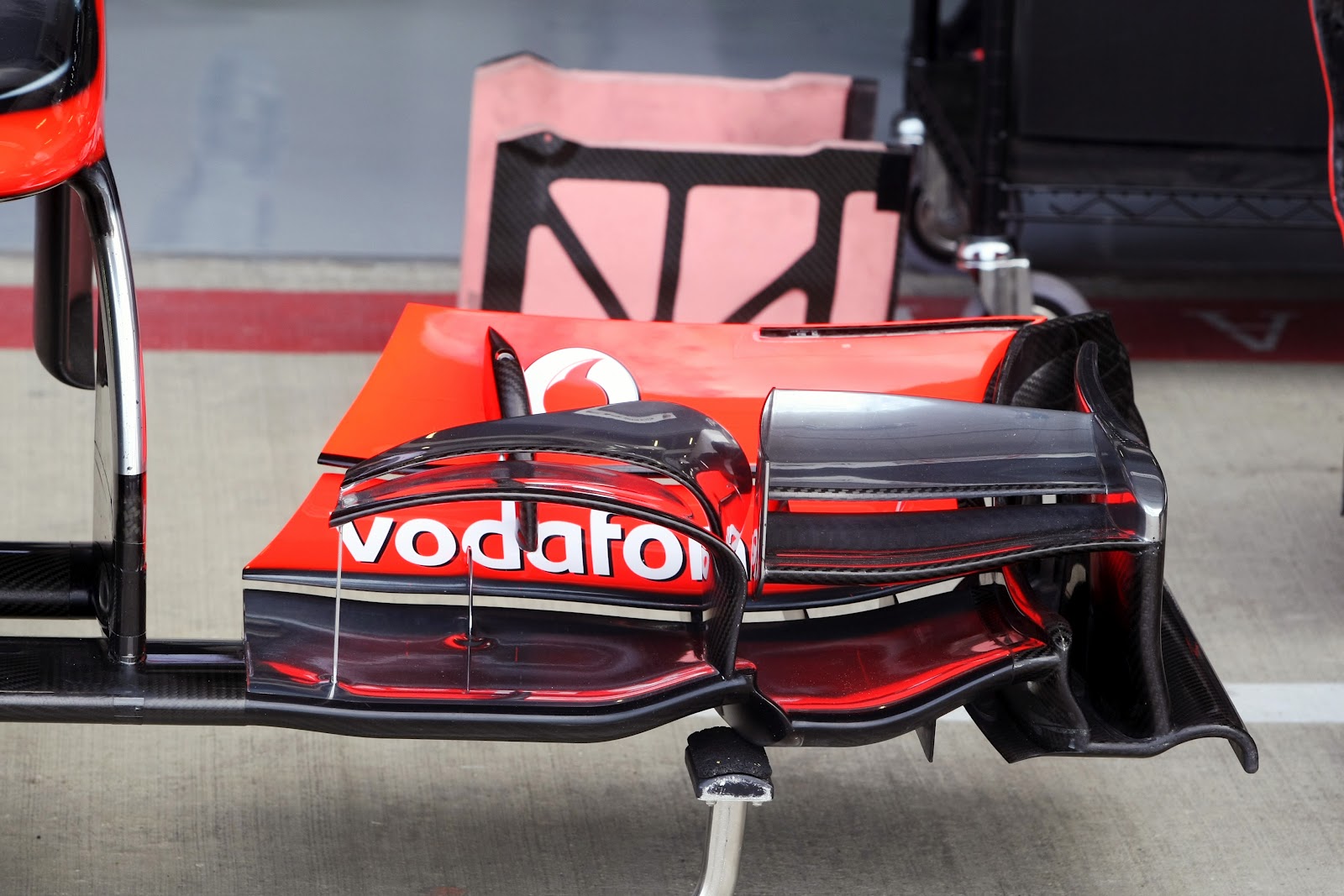

Directing the flow inwards is shown to be beneficial in the paper but it must be remembered that the paper talks about the 2009 front wing (i.e. the short span wing). That wing placed the endplate approx. in front of the inner shoulder of the front tyre. It makes sense in that situation to direct the flow / vortices inwards of the tyre because otherwise you have to get sufficient energy in to the flow to turn it through approx. 80deg and get it across the moving face of the tyre. Look at the McLaren front wing of the period to see how they obviously designed the endplate to direct air inwards.

The -23 is on the right. See how they sacrificed ultimate wing area to allow an inward turning endplate (which gave a large footplate too which is also probably beneficial to the overall efficency of the front wing).

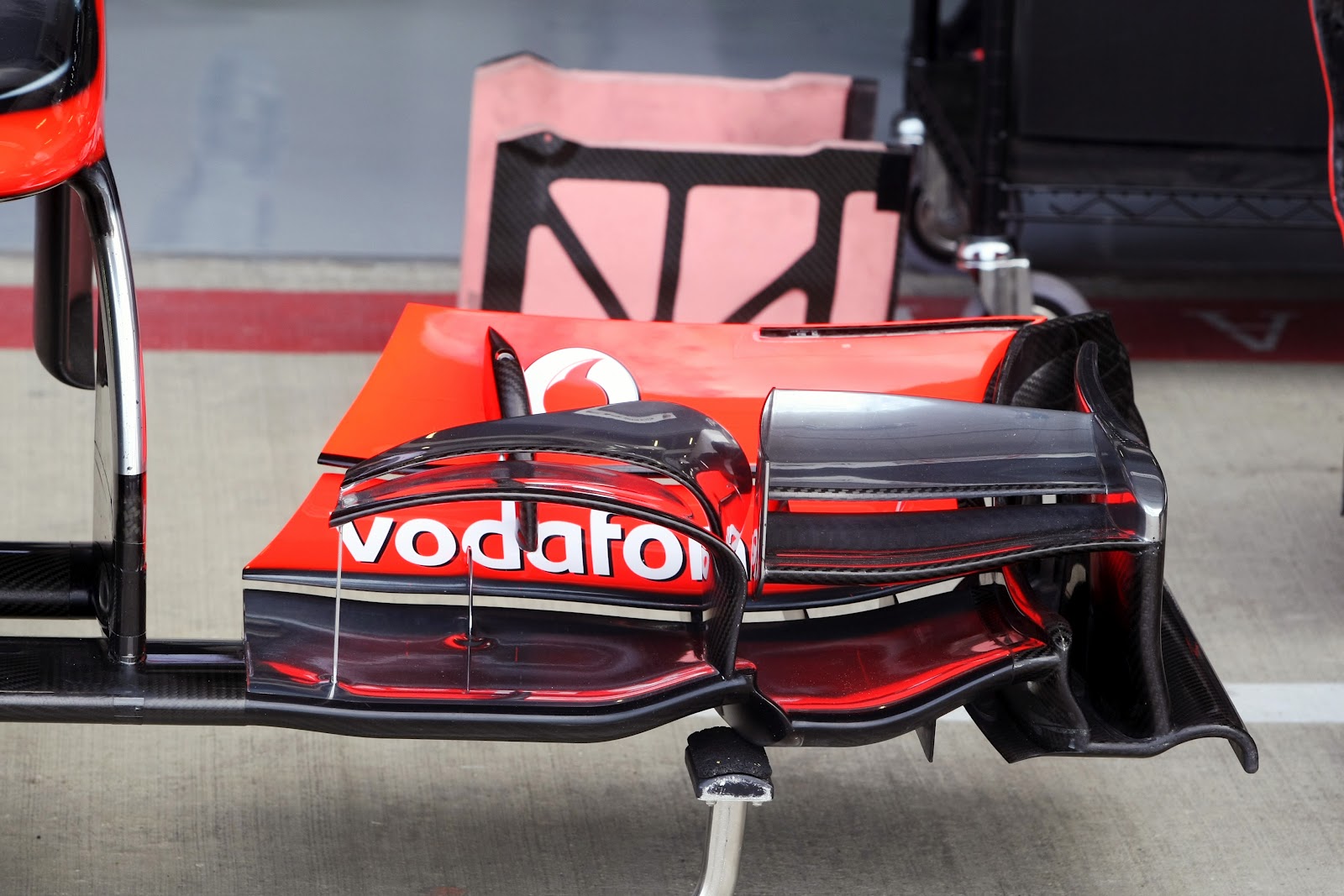

So we are left with the option of turning the flow outwards around the tyre. Look at the current endplates and you see that they are designed to turn the flow outwards:

Indeed, looking at the current McLaren wing, it appears to me that the cascade wings on top of the front wing are, in part at least, designed to help the outward flow. Look at the inboard of the two cascades and you can see that the long radius bend has a long, heavily cambered, chord that appears to be trying to direct air outwards. The apparent close coupling of this section and the outer cascade suggests that the outer one is being used to help drive the turning effect of the inner cascade. The endplate itself is split in two with the main, inner section having a marked outwards bend to it. This will direct air outwards (as well as increasing the expansion of the volume below the outer most part of the front wing). Note also how the endplate has been brought inwards to give a large footplate again - this is obviously an important part of making the wing work effectively.

I think there can be little doubt that the current methodology is to turn the flow outwards around the front tyre.

If you are more fortunate than others, build a larger table not a taller fence.