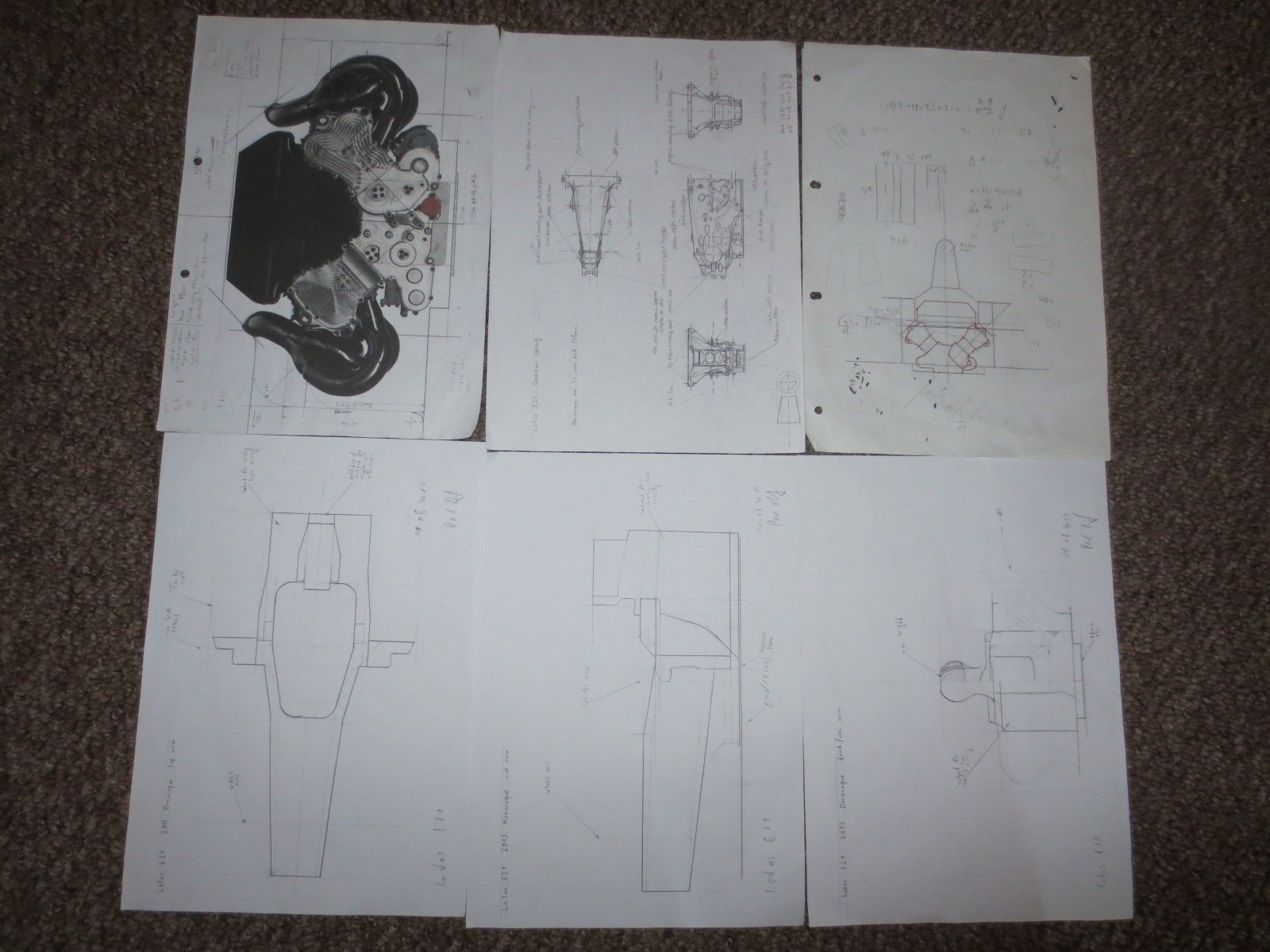

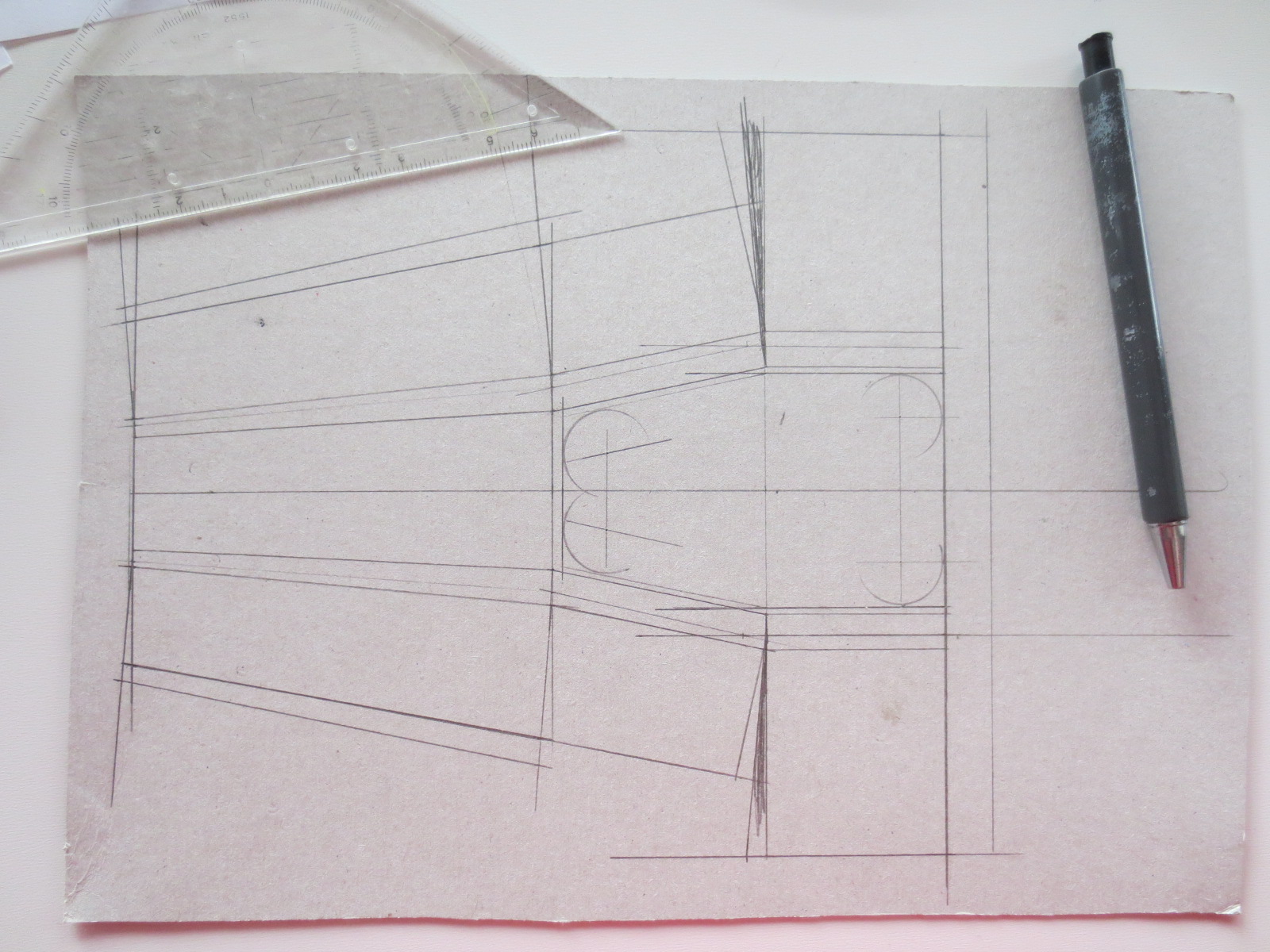

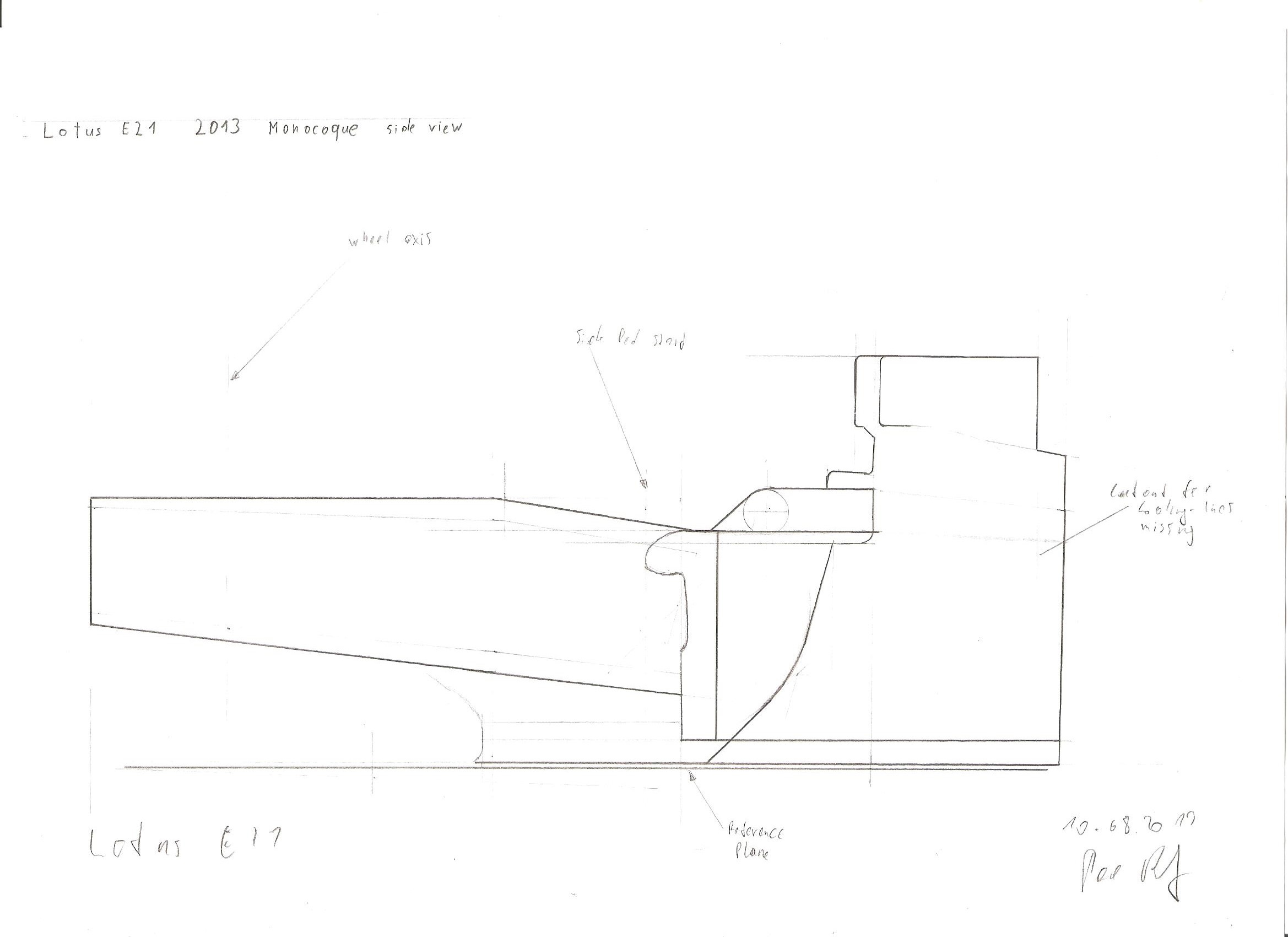

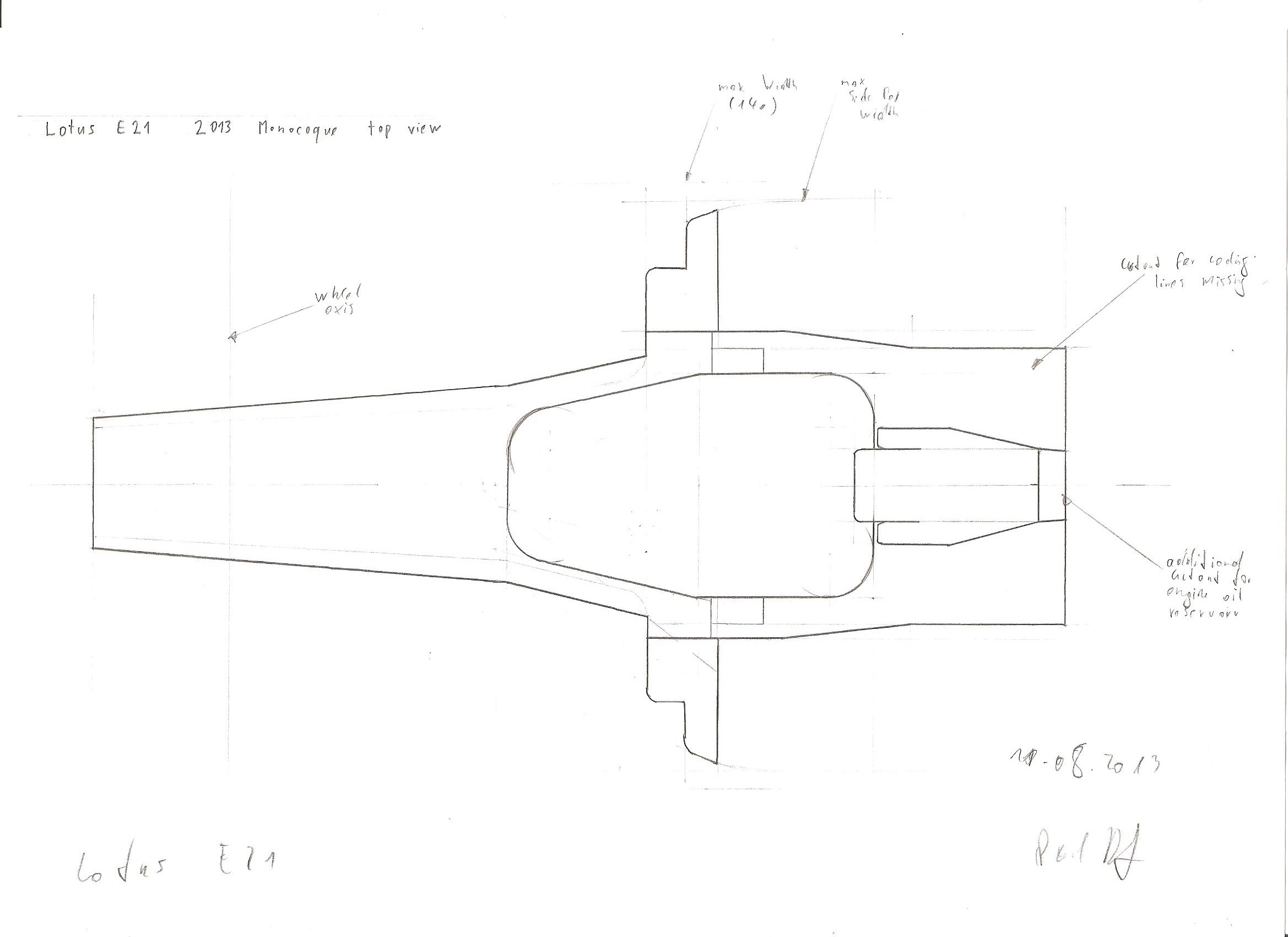

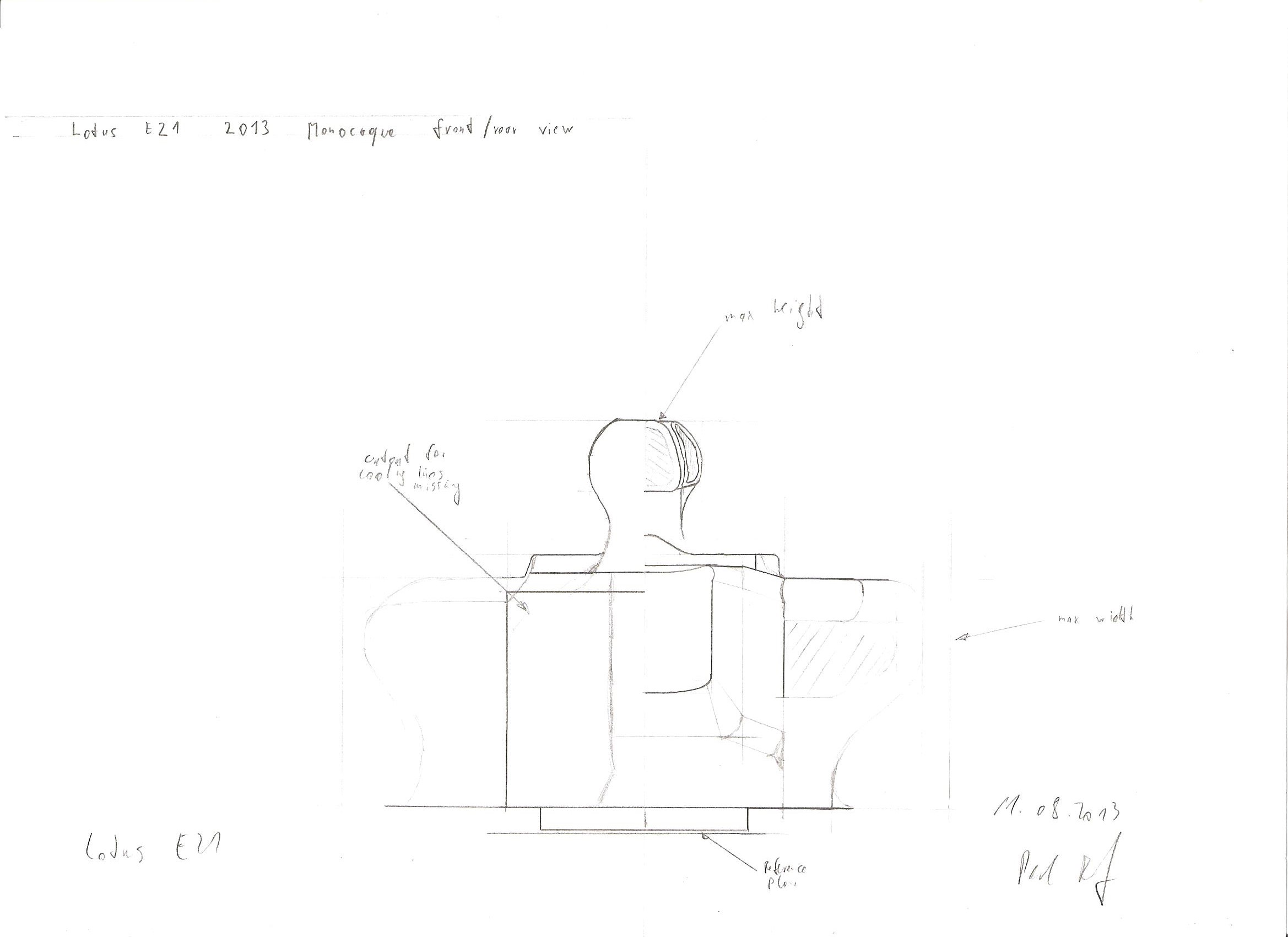

Last night I started with the first basic drawings for the monocoque of my new project, the Lotus E21 of Kimi Räikkönen - btw. my absolute favourite driver.

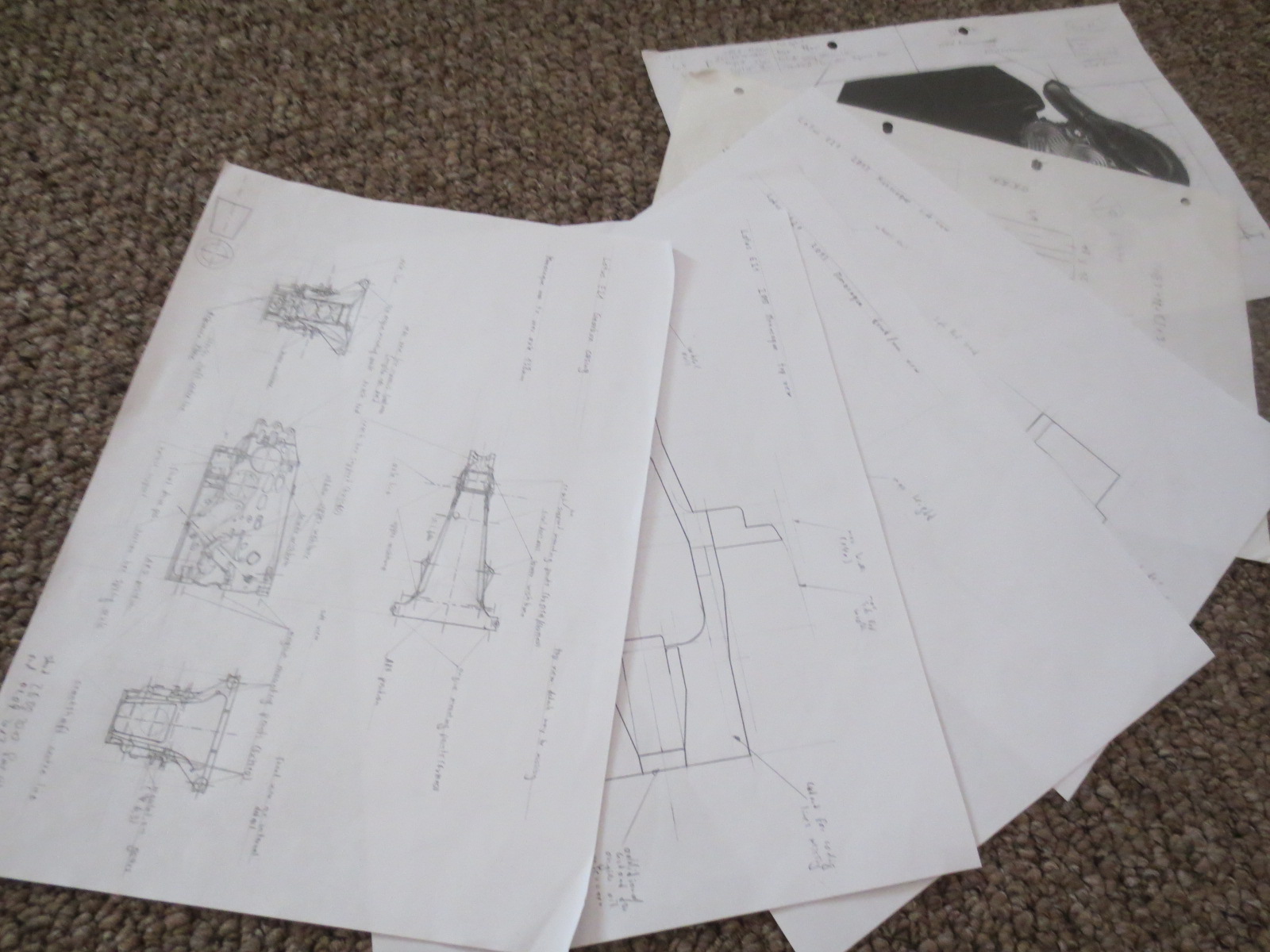

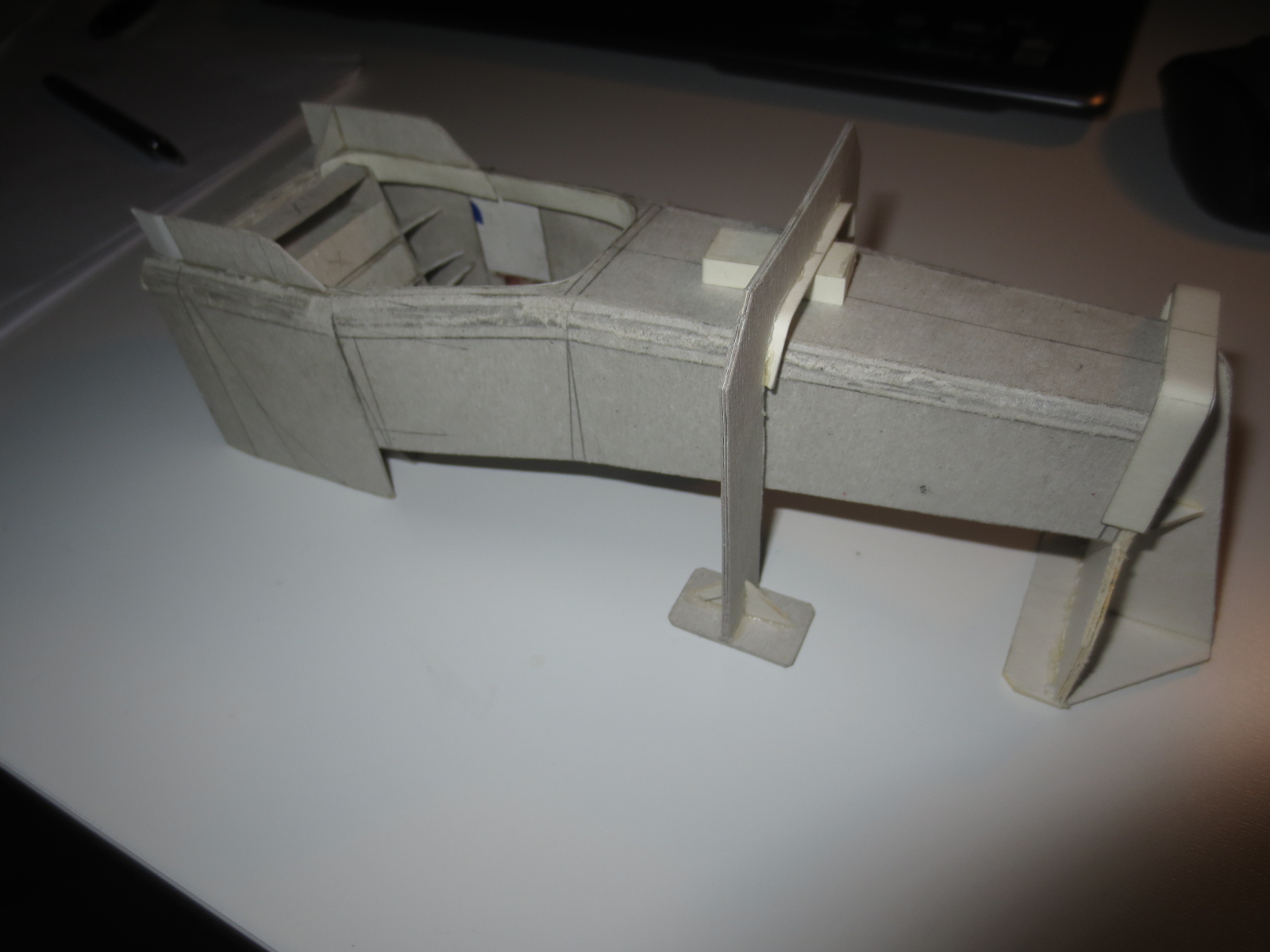

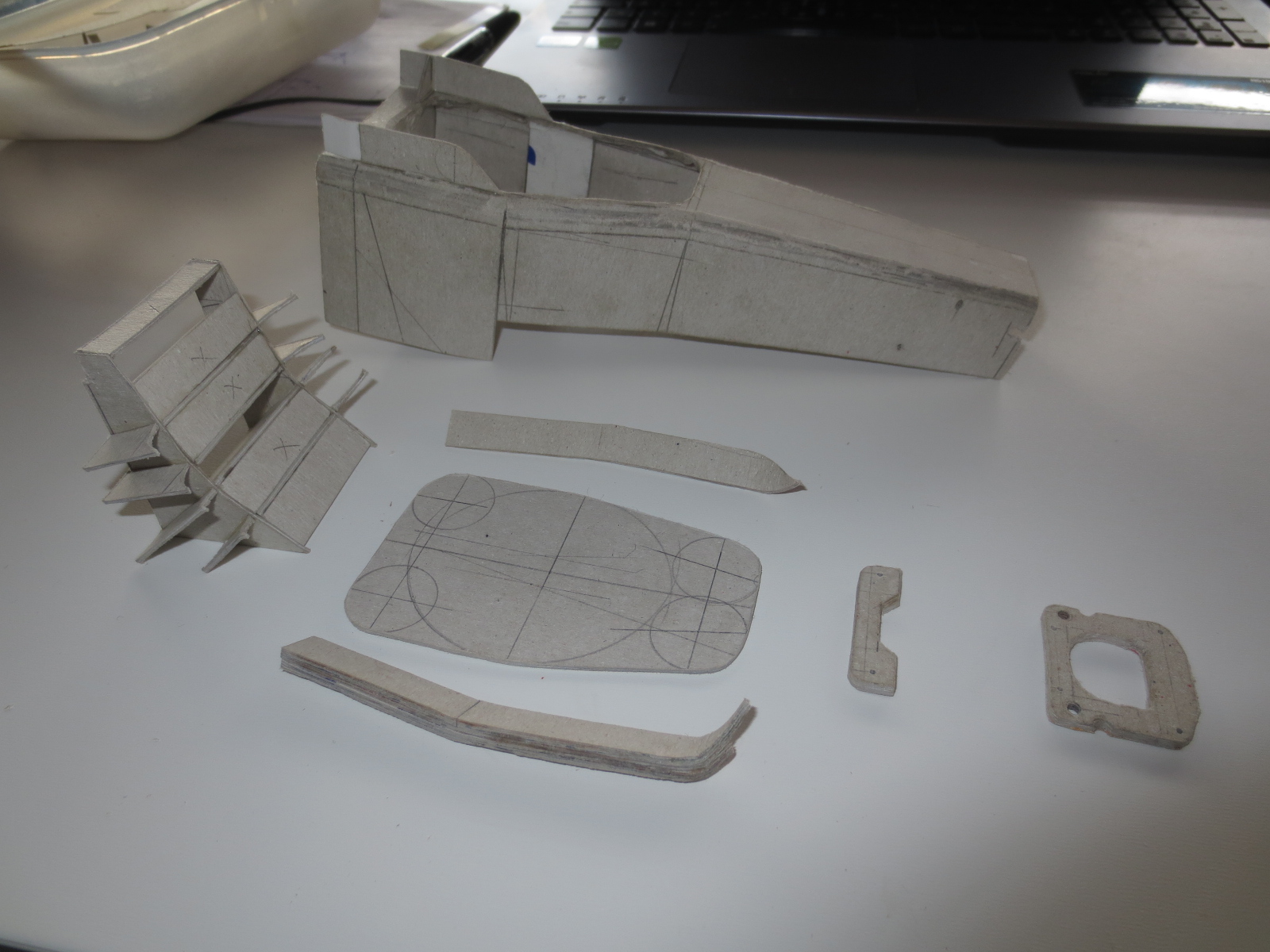

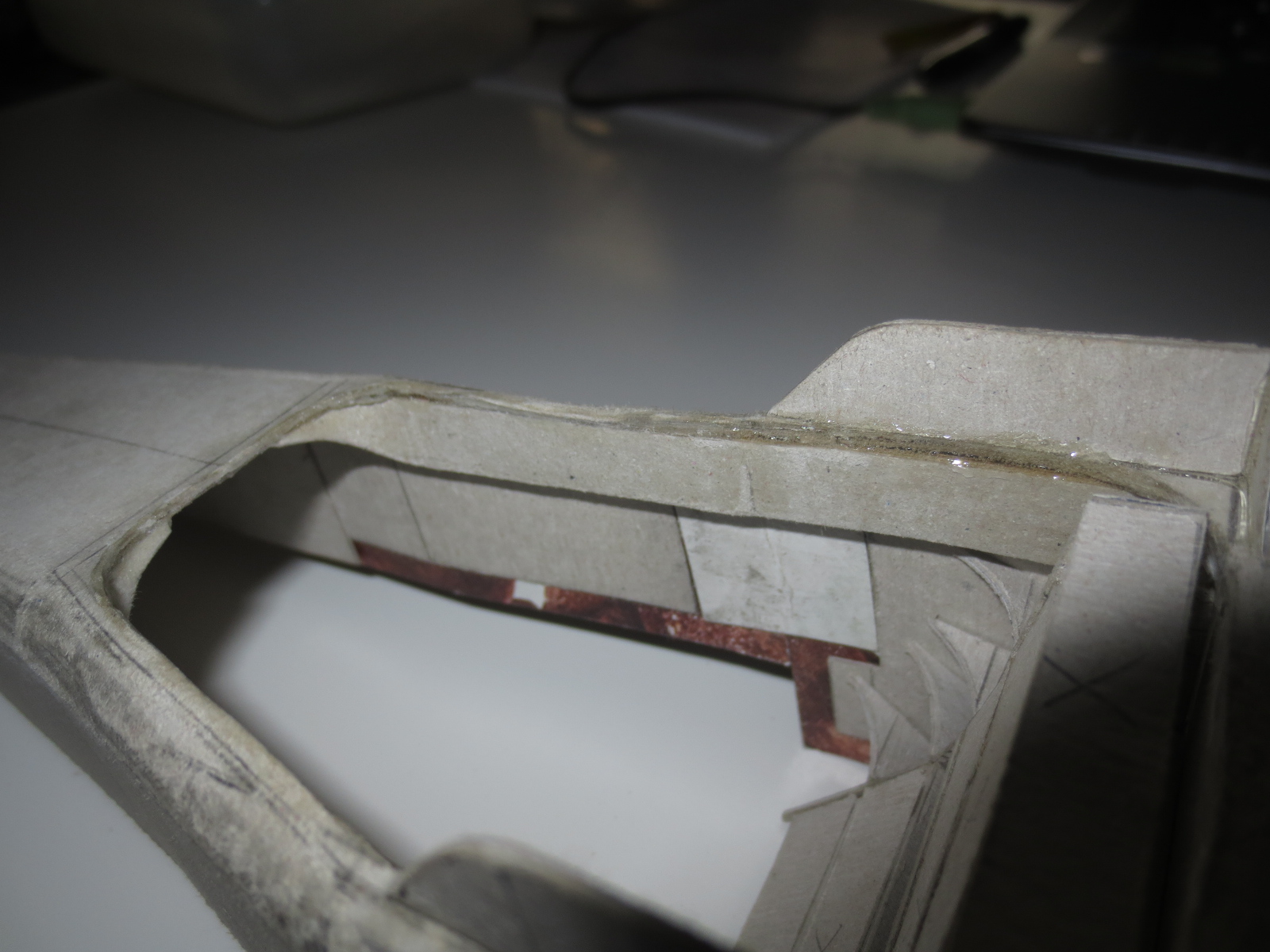

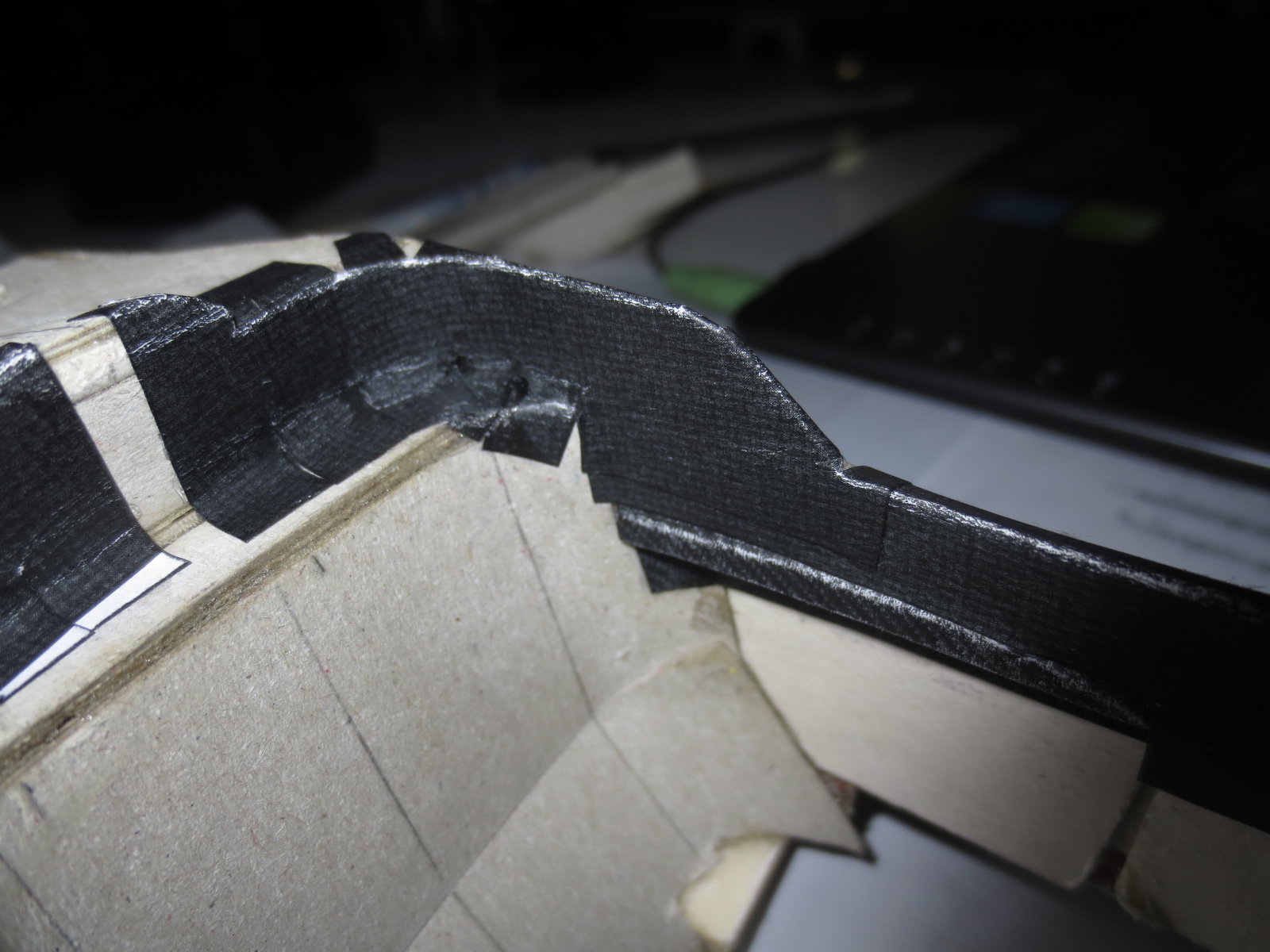

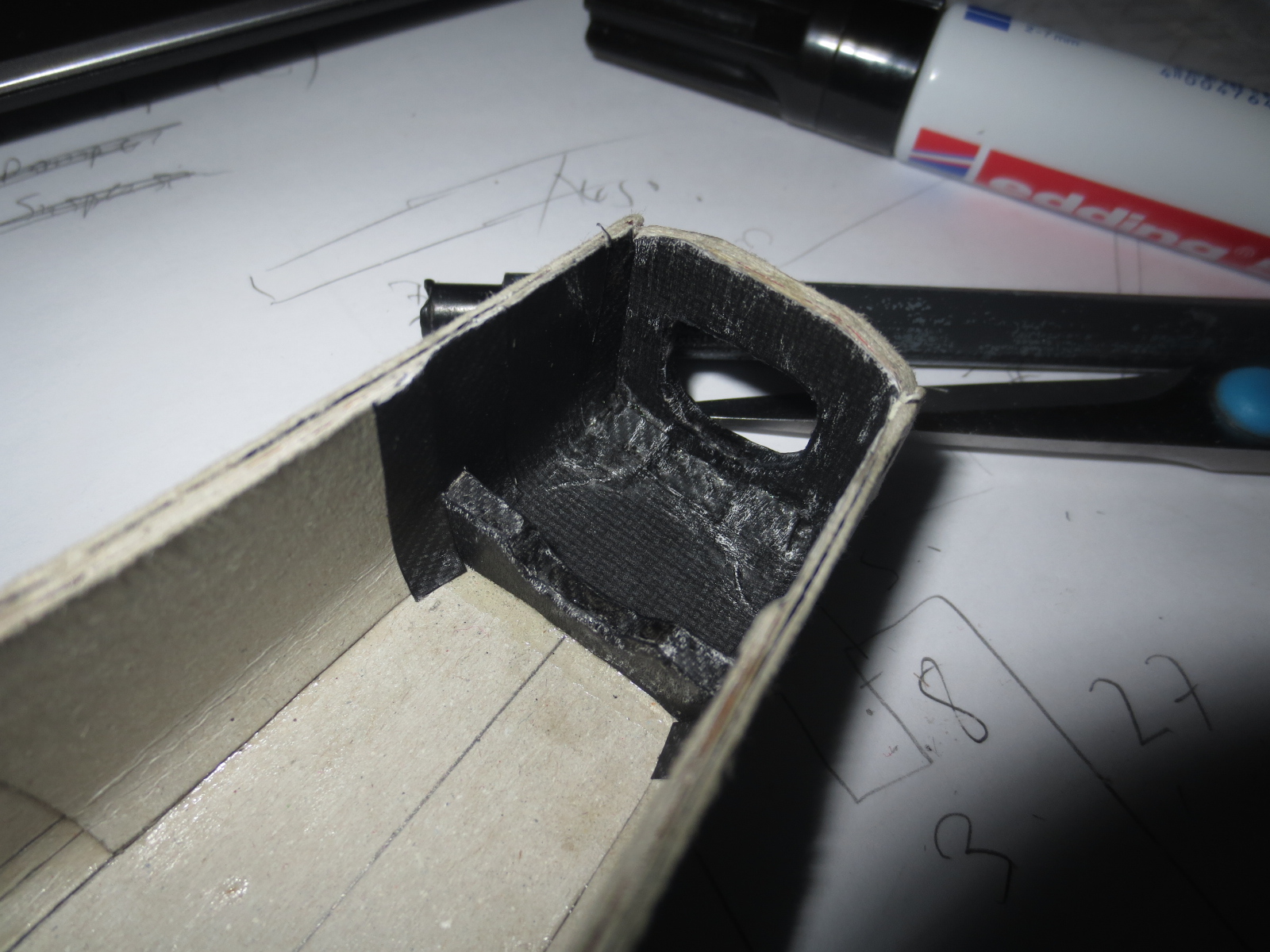

A bit work is left at the rear of the monocoque and at the side pods. At the rear I couldn't reconstruct the correct shape of the cutouts for the cooling lines (water and oil radiator). I hope a few new pics will appear at the GP of Belgium in two weeks where I can spy out the correct shape of this cutout. I've already tried to reconstruct the shape of this cutouts at the predecessors E20 and R30 but didn't find anything helpfull. The correct side pod shape I'll recalculate when I'm starting with the manufacturing of idems.

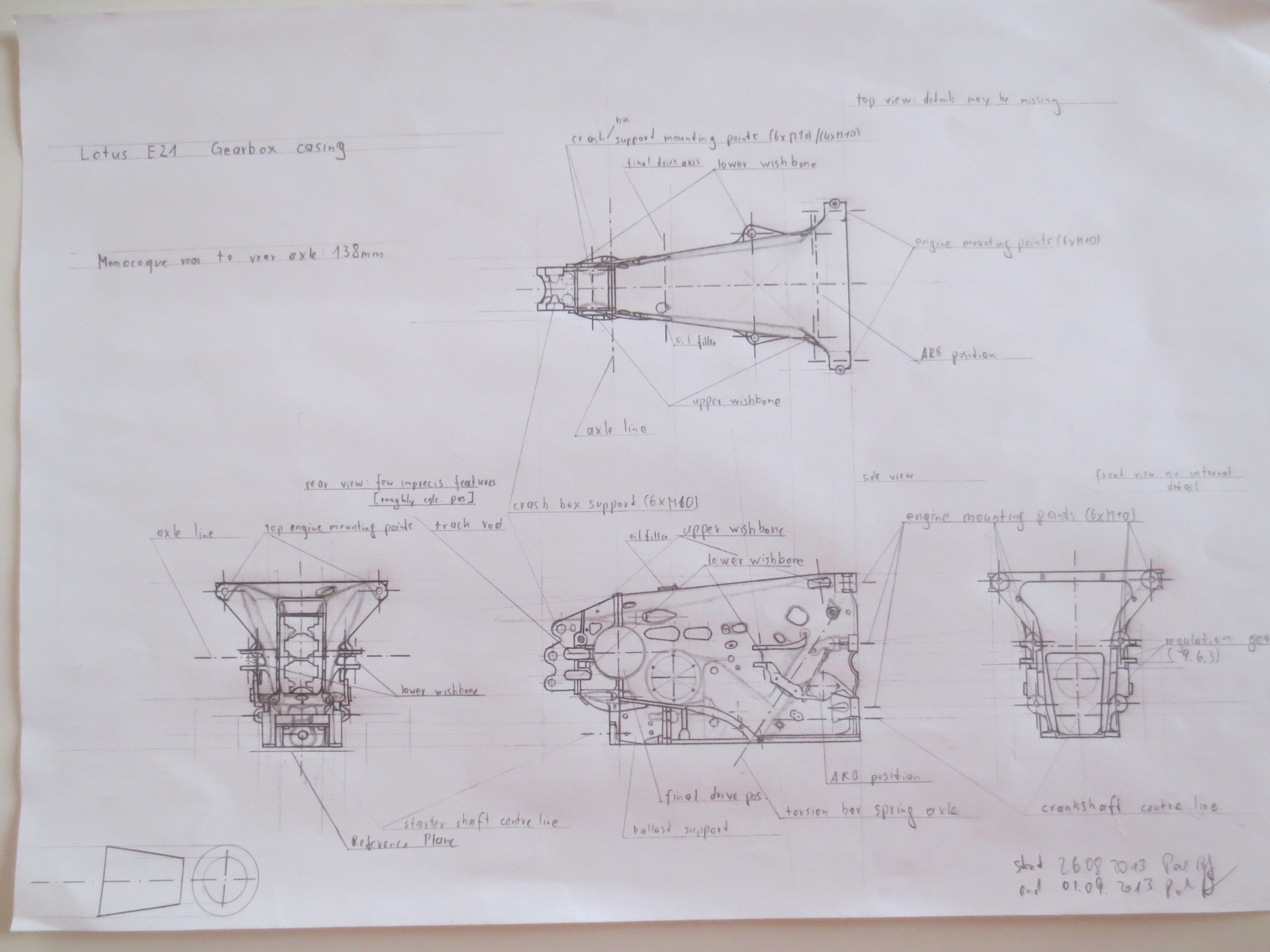

The engine drawings I can take over from the RB7. It's Renault RS27-2011 is quite the same as the E21's RS27-2013. I've to look if I can find some visible changes between this two versions.

Since the start of the season I've collected 397Mb data from this car. About 1012 pics, tech. regs with appendix, some publications, tech. analysis and so on. A few additional data I collected from the predecesser E20 in case of the engine/engine mounting. a short comparison to my last F1 built, the Red Bull RB7: There I had 277Mb data et the end of the building process. So we can await a much more detailed model of the Lotus than it was at the RB.

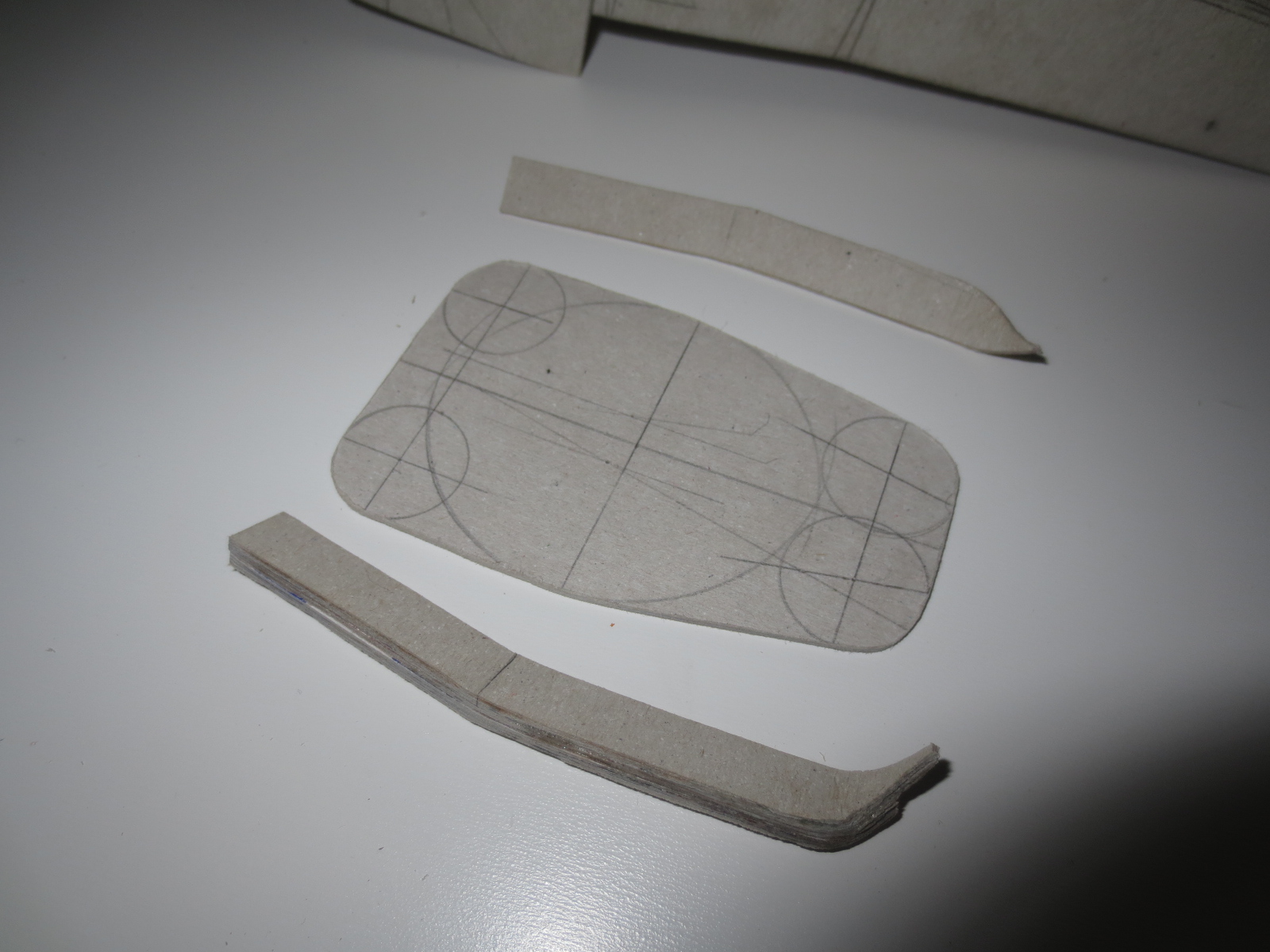

Lotus E21 Monocoque - side view drawing

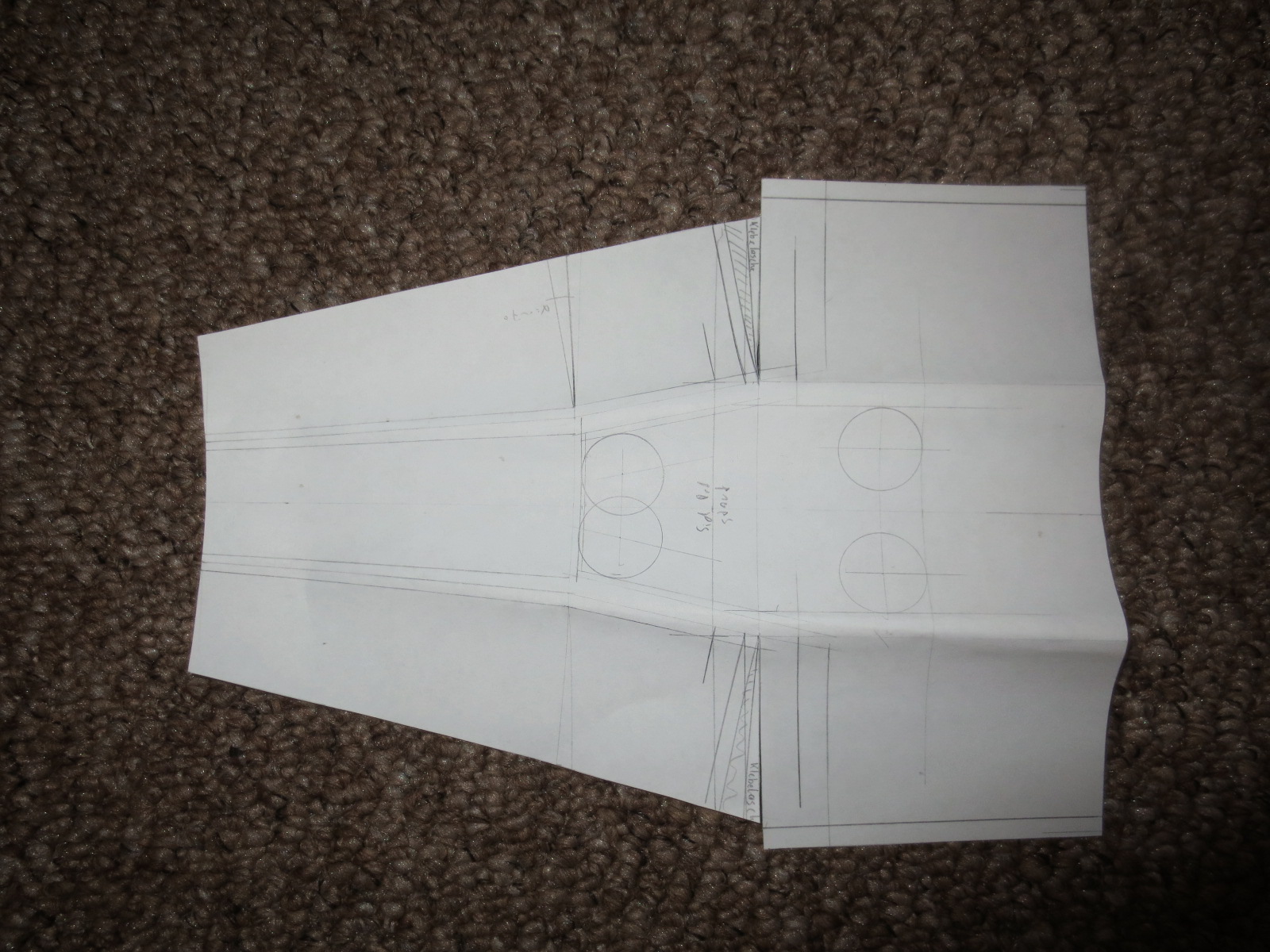

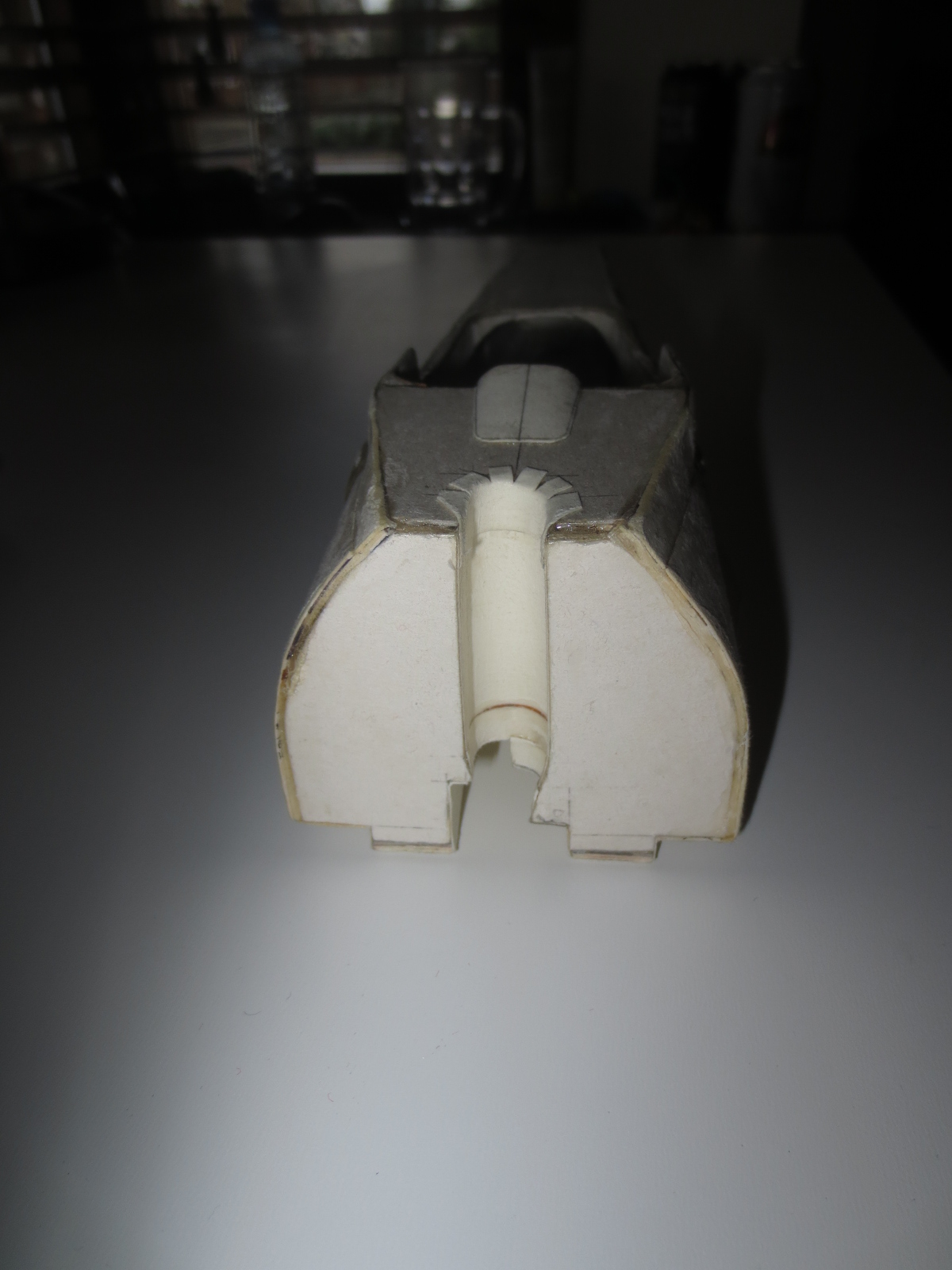

Lotus E21 Monocoque - top view drawing

Lotus E21 Monocoque - front/rear view drawing

That's it of the mo, thx for watching.

Cheers,

Paul