Bill, I hope to get the silicone port model captured via 3d scanning so that will be interesting too.Billzilla wrote:That will be most interesting, thanks.Brian.G wrote:I will provide all of the above next week, no problem.

Brian,

Bill, I hope to get the silicone port model captured via 3d scanning so that will be interesting too.Billzilla wrote:That will be most interesting, thanks.Brian.G wrote:I will provide all of the above next week, no problem.

Thats fair enough, I was just pointing out that sand casting, or gravity die with sand cores does not create poor parts - you have to take other elements on board too such as metallurgy, fill method, metal handling pre pour and also heat treatment.strad wrote:Brian..I know for a fact the Renault used to have to toss heads after a race, and it was because the stress and vibration would fill them with spider web cracks. It was also a time when MOST of the engine was disposable.. Engines didn't have to last like now.

You could do, but If I was doing a cover such as this I'd probably cnc machine from billet since its a 'fairly' simple part with not much internal ways bar the tapered coolant tube. I see a fair few of the newer F1 covers are machined this way, and not cast. A good example below of a billet cover, taken again, in Maranello.Brian.G wrote:If you're planning to make a more than a few, how about shell-casting those cam-covers?xpensive wrote:Its hard to tell on the gear cover, it looks like a billet machine item, but the cam cover is defiantly sand cast yes.Brian.G wrote:

http://www.google.com/search?q=renault+ ... 680%3B1095

...

Ill guesstimate say 200euro for the billet, and about 15hrs machine time pending spindle speed, not counting stress relief after roughing,Brian,

I guess, if you're insensitive to cost, I cannot imagine what those Ferrari covers would cost to machine, holy cow.

Most water-cooled aluminum heads are still sand cast. But modern sand casting techniques are capable of producing much higher quality castings than was possible just 10 or 15 years ago. The biggest changes are the availability of accurate digital analysis tools for evaluating the solidification of castings and the flow characteristics of liquid metal in the molds.Brian.G wrote:Thats fair enough, I was just pointing out that sand casting, or gravity die with sand cores does not create poor parts - you have to take other elements on board too such as metallurgy, fill method, metal handling pre pour and also heat treatment....I would imagine even the modern heads are made using sand, either as the main moulds, or the cores. The only difference being the way the mould filled, and whats done while its cooling(Centrifugal holding jigs, in mould heat pipes etc)....Brian,

Yes - totally agree, an example of the casting below in link for those who have not seen it,riff_raff wrote:Most water-cooled aluminum heads are still sand cast. But modern sand casting techniques are capable of producing much higher quality castings than was possible just 10 or 15 years ago. The biggest changes are the availability of accurate digital analysis tools for evaluating the solidification of castings and the flow characteristics of liquid metal in the molds.Brian.G wrote:Thats fair enough, I was just pointing out that sand casting, or gravity die with sand cores does not create poor parts - you have to take other elements on board too such as metallurgy, fill method, metal handling pre pour and also heat treatment....I would imagine even the modern heads are made using sand, either as the main moulds, or the cores. The only difference being the way the mould filled, and whats done while its cooling(Centrifugal holding jigs, in mould heat pipes etc)....Brian,

Another major improvement is the use of digital inspection equipment (CMM's) to ensure accurate positioning of mold pieces such as cores. This allows tighter control of features like cast wall thickness, which in turn results in more consistent fatigue life of castings.

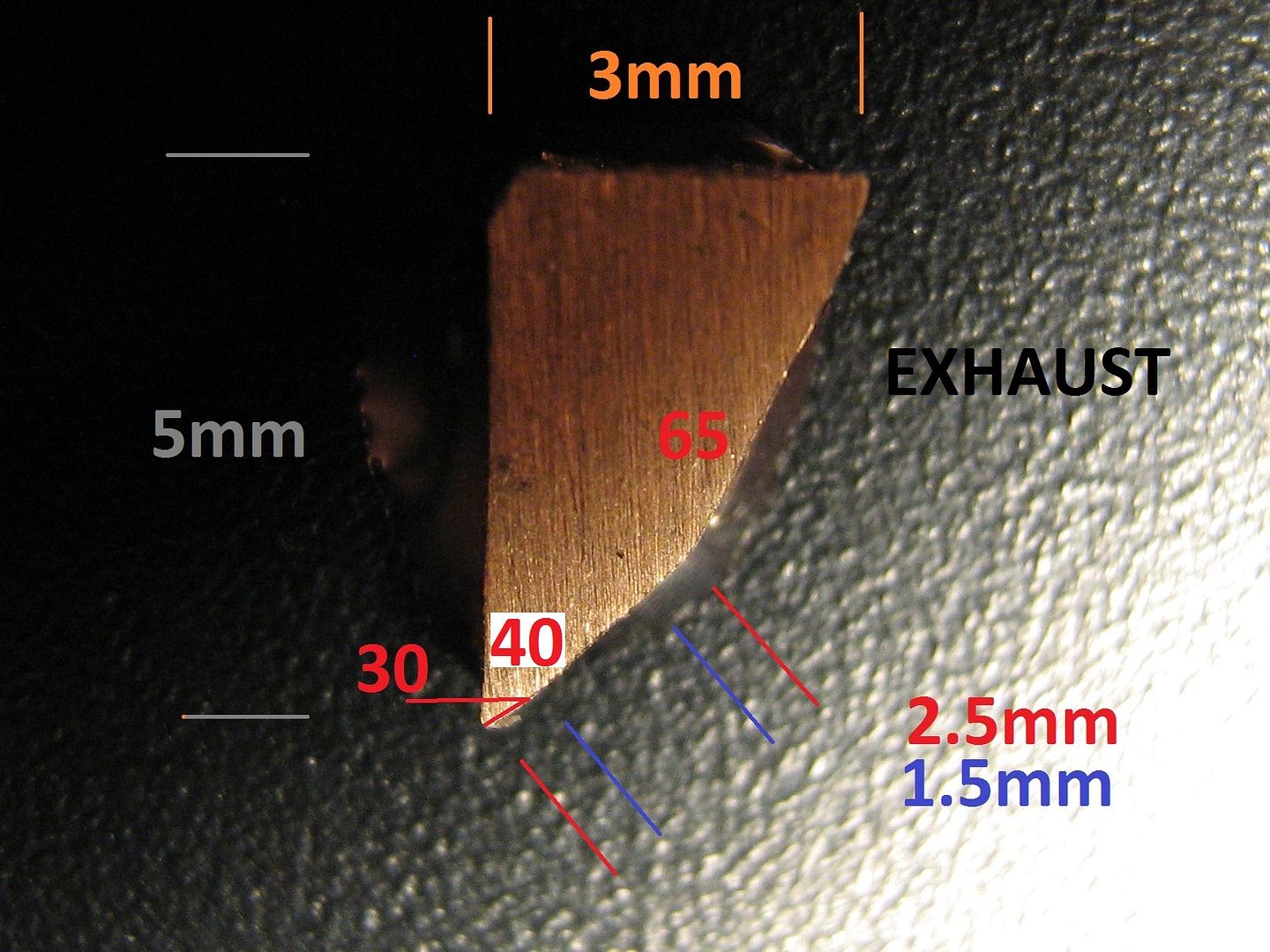

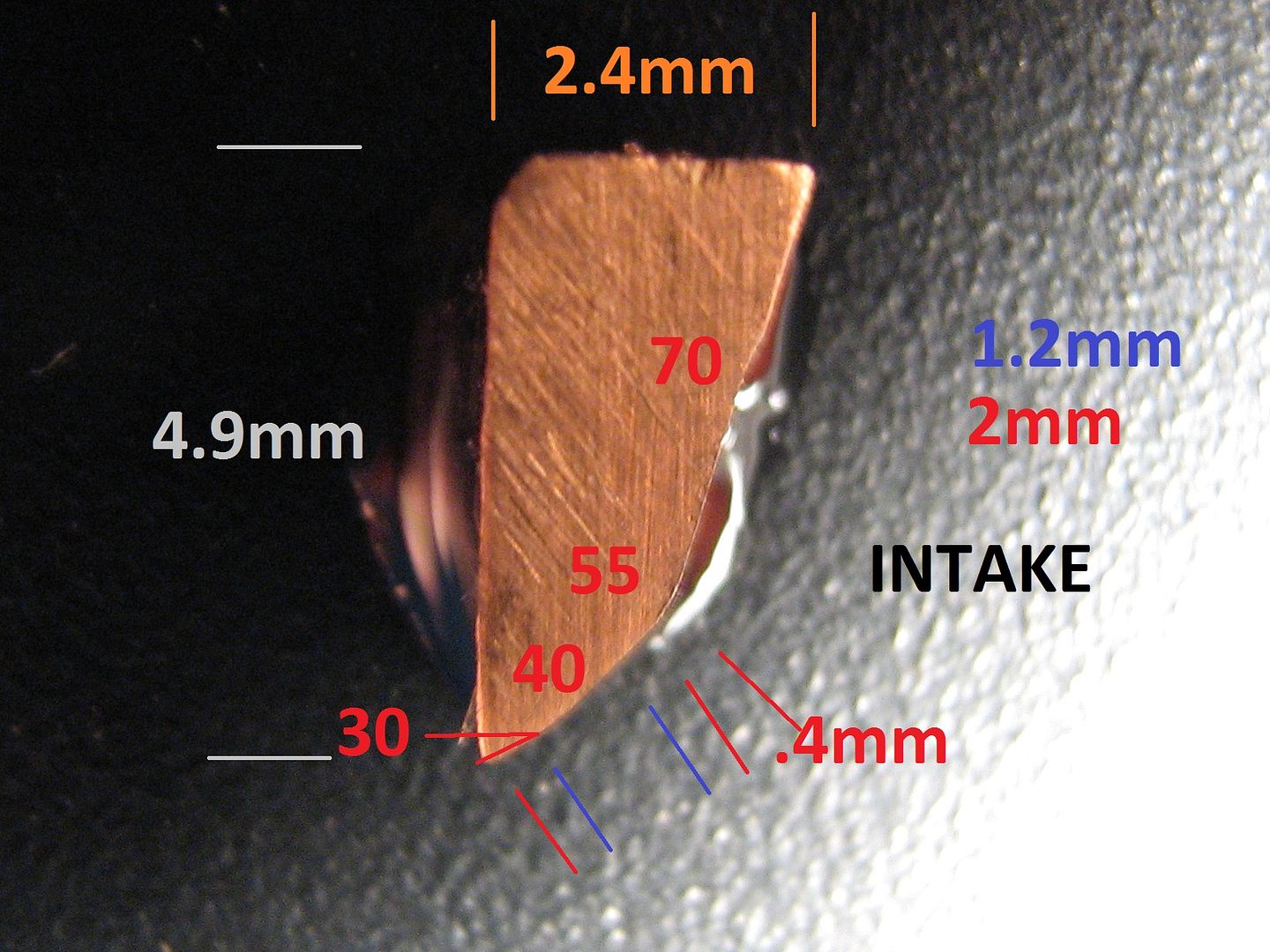

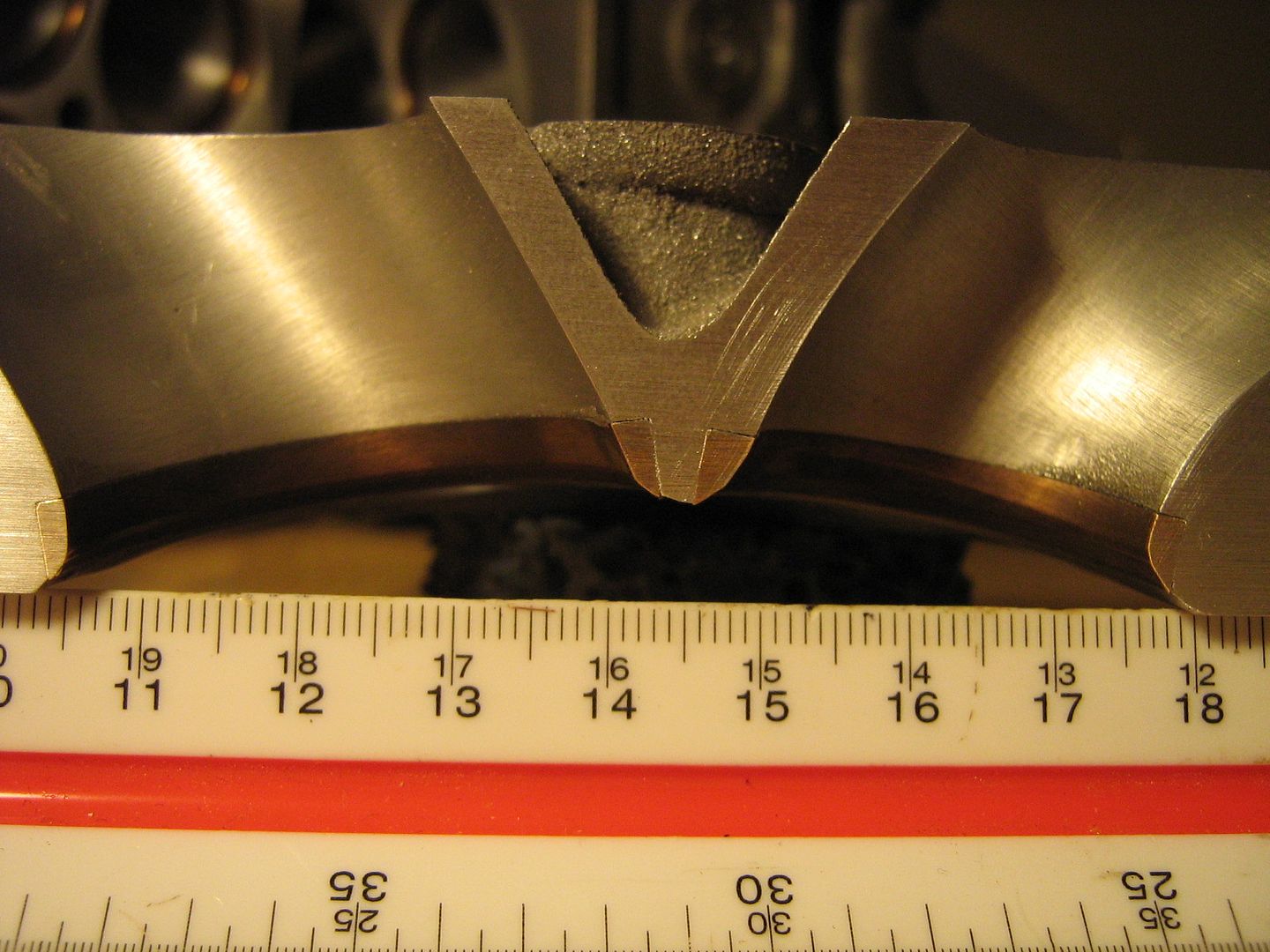

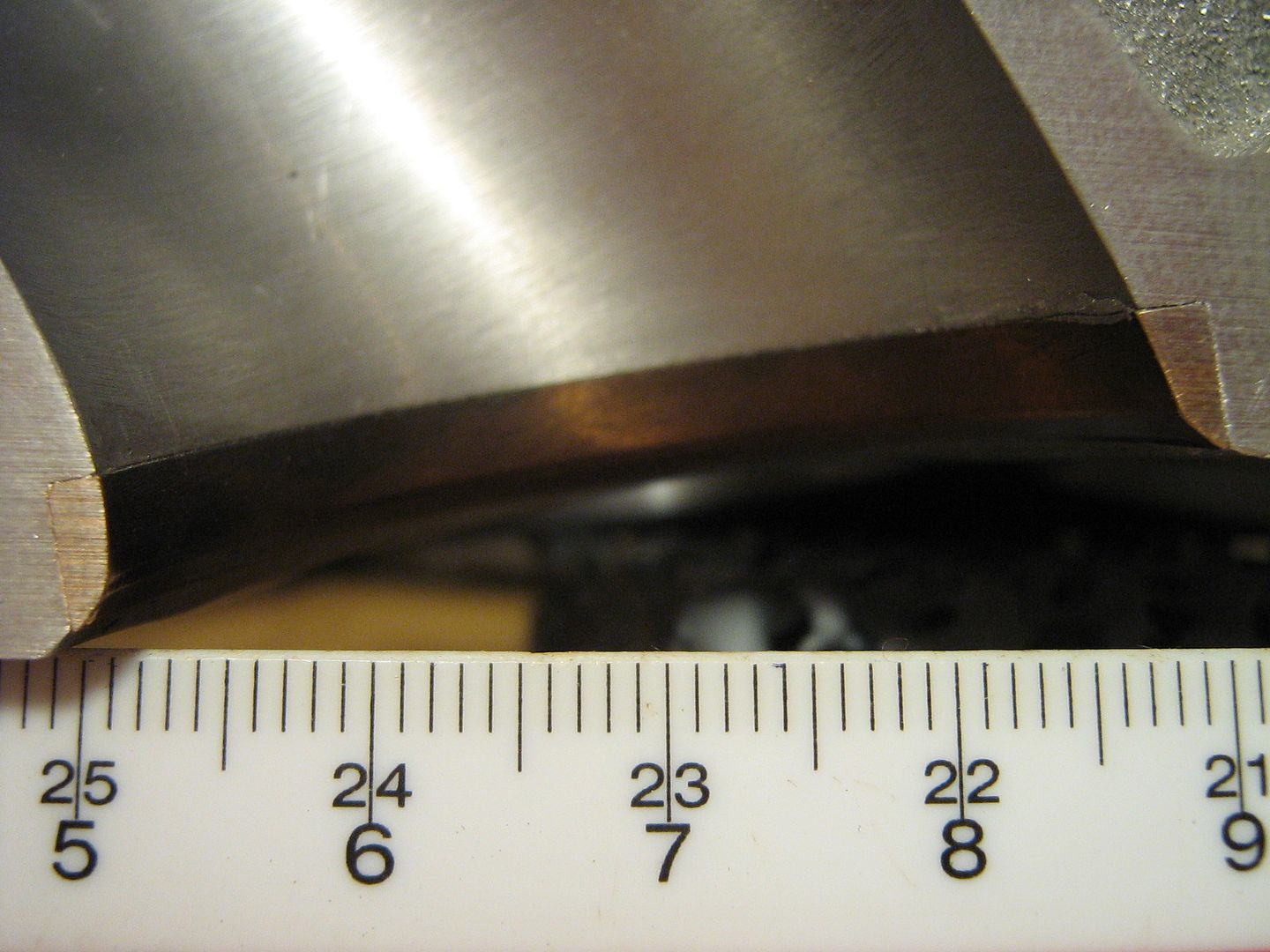

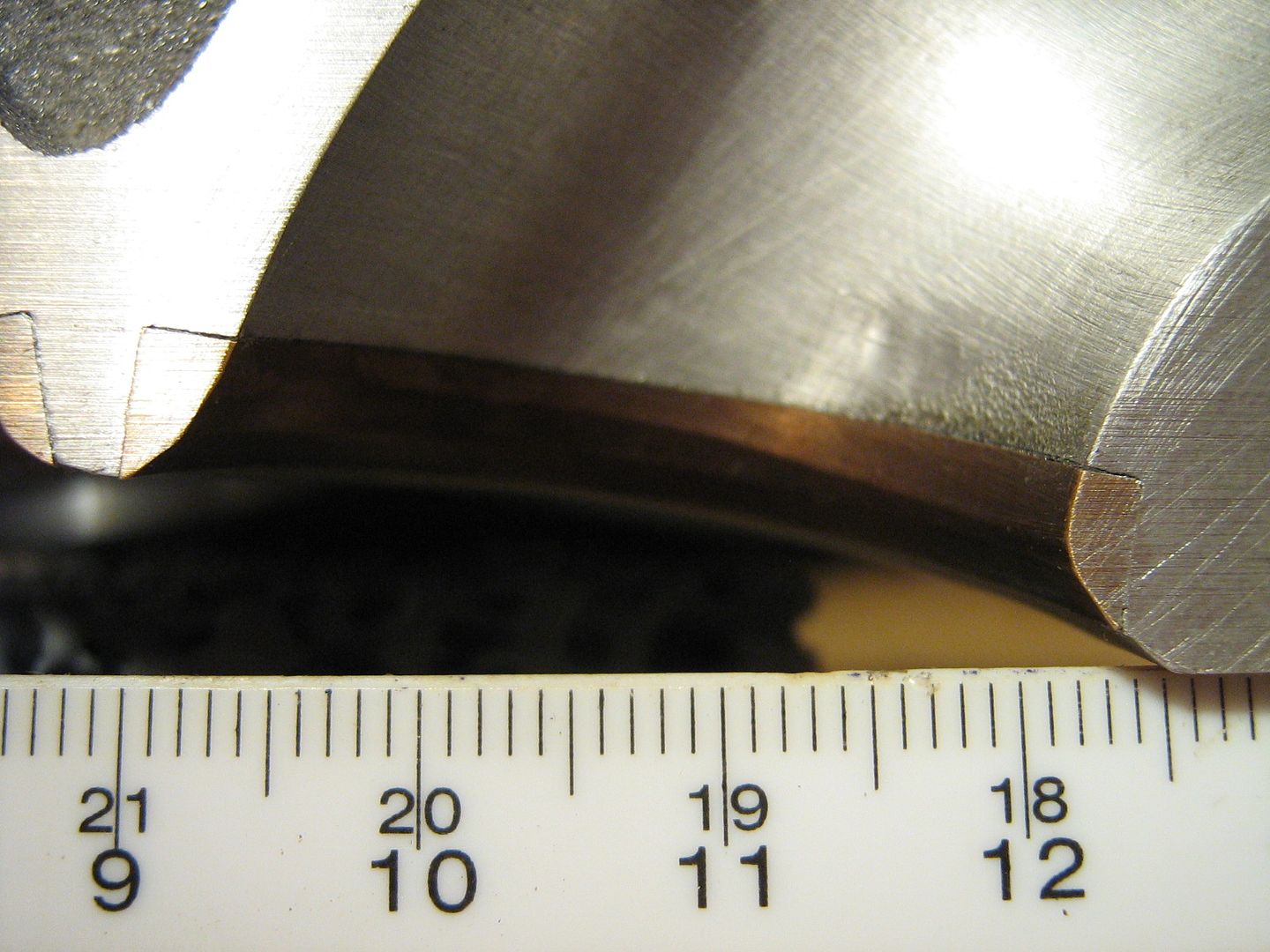

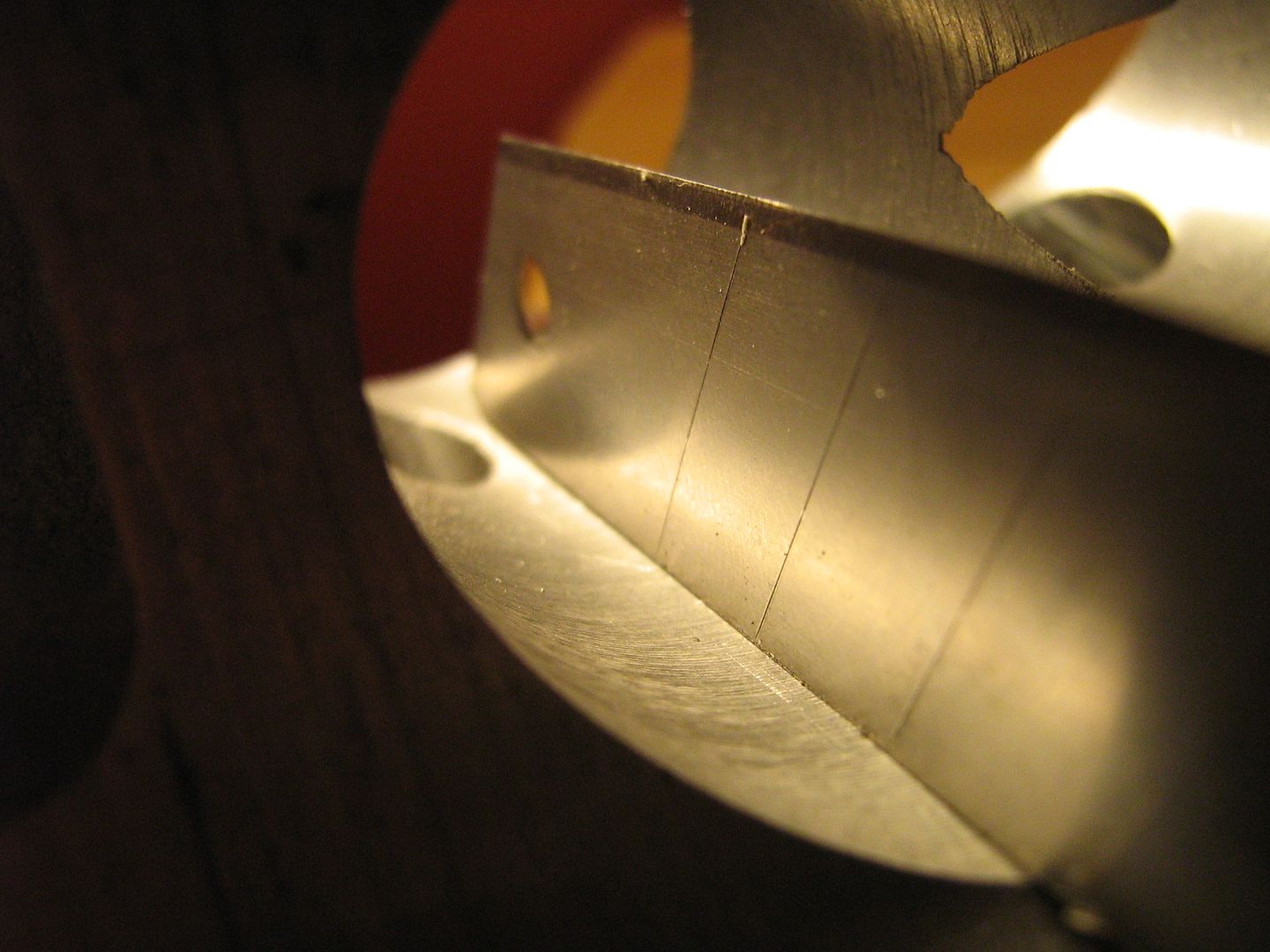

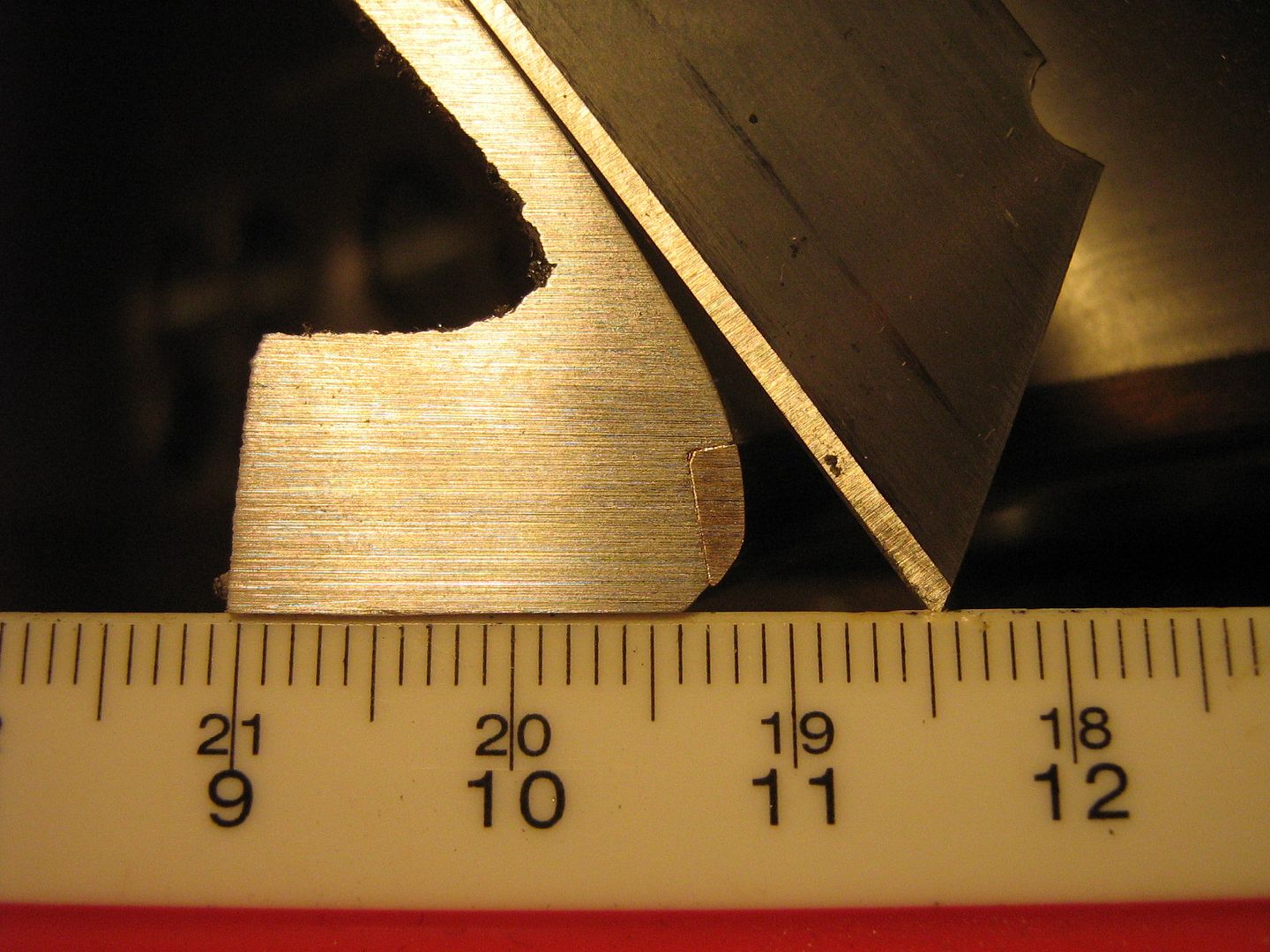

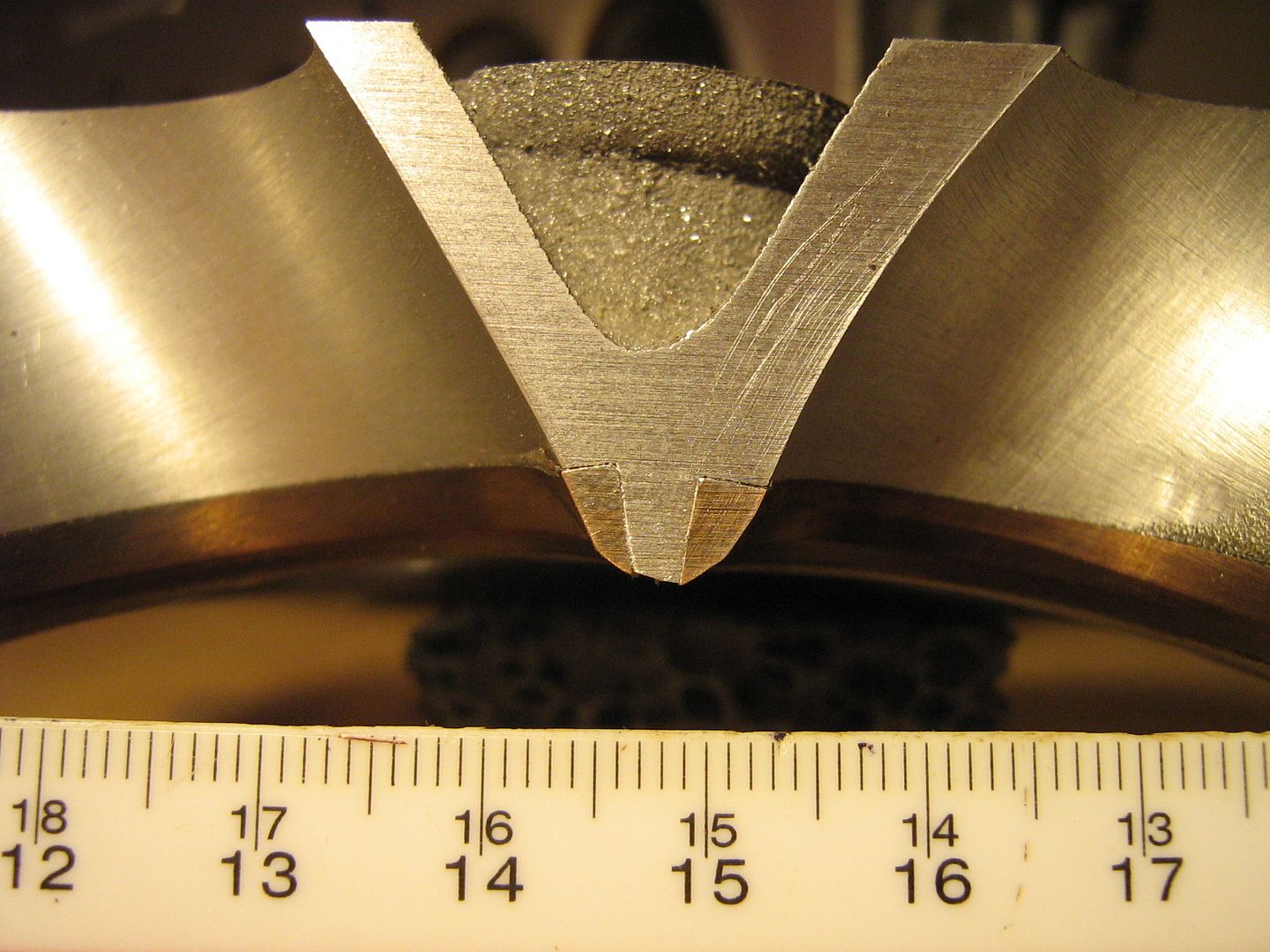

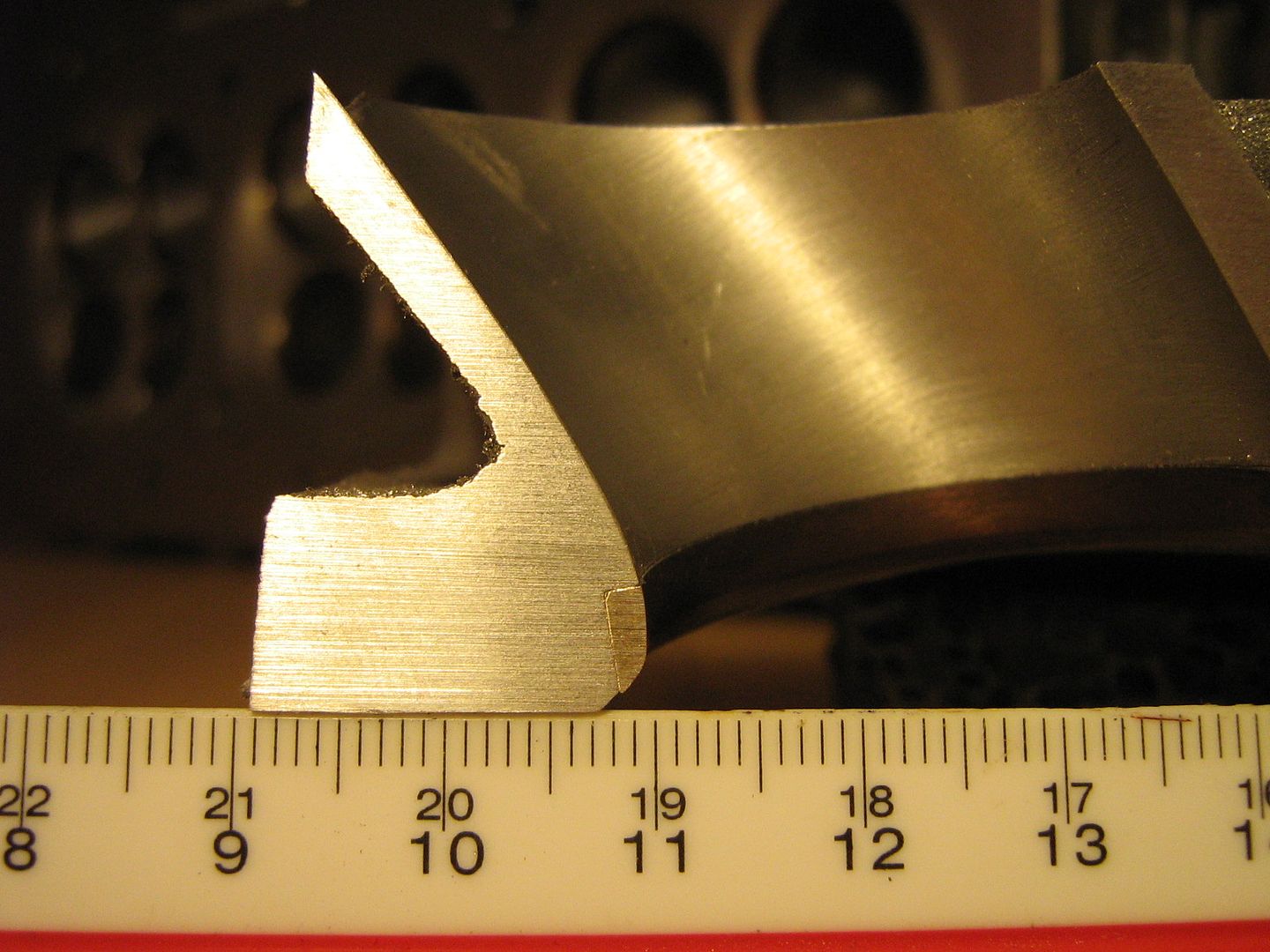

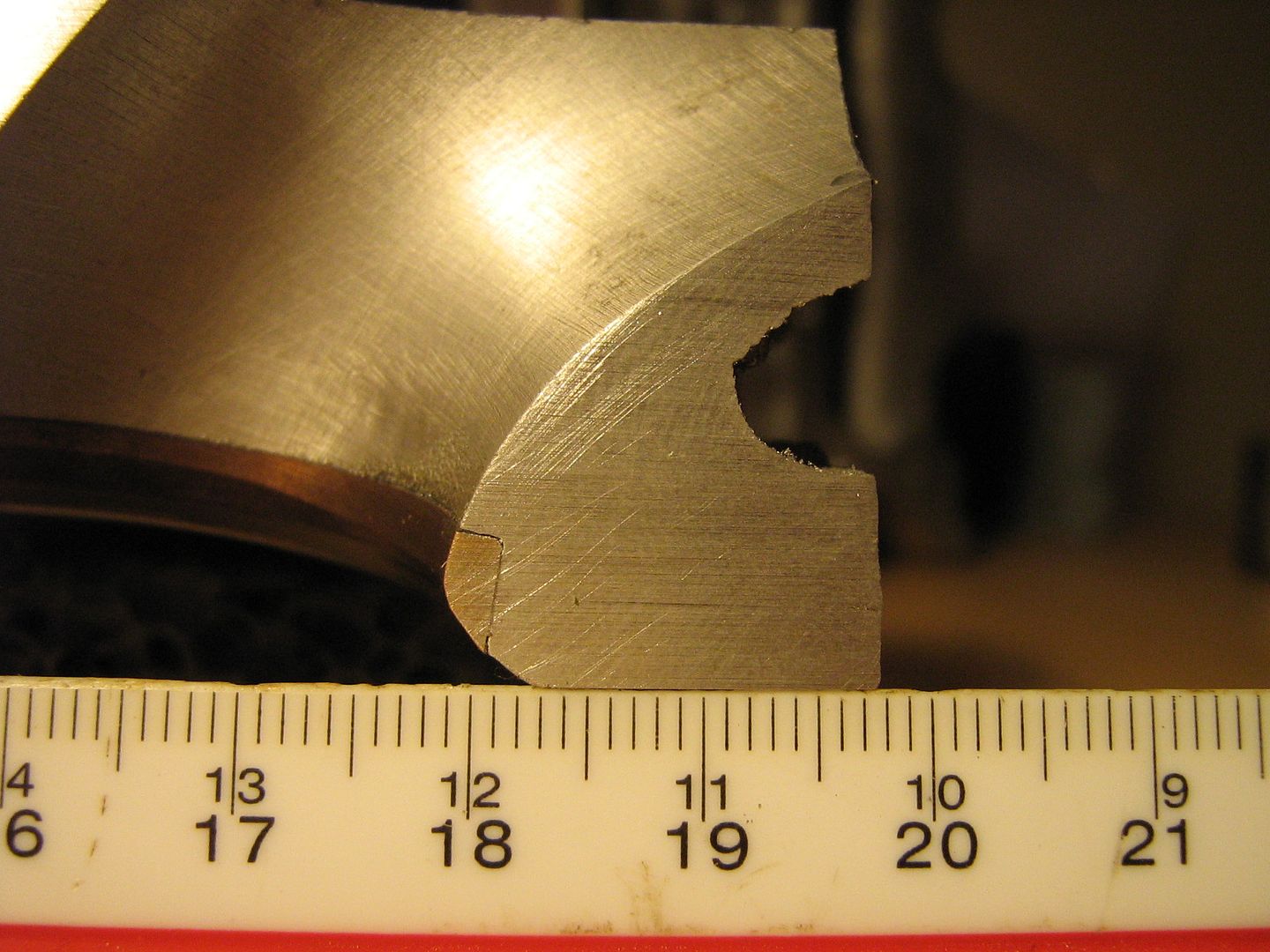

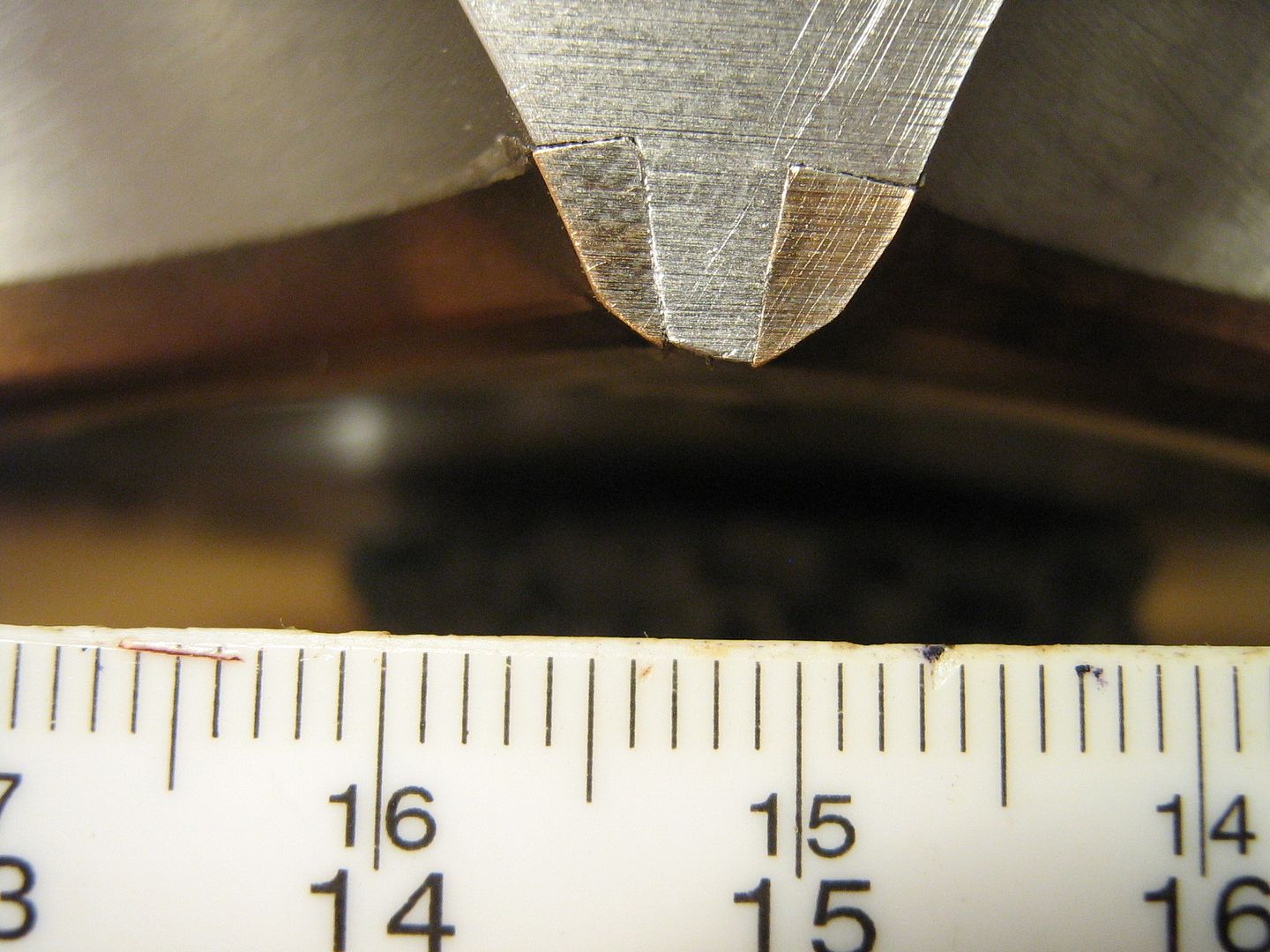

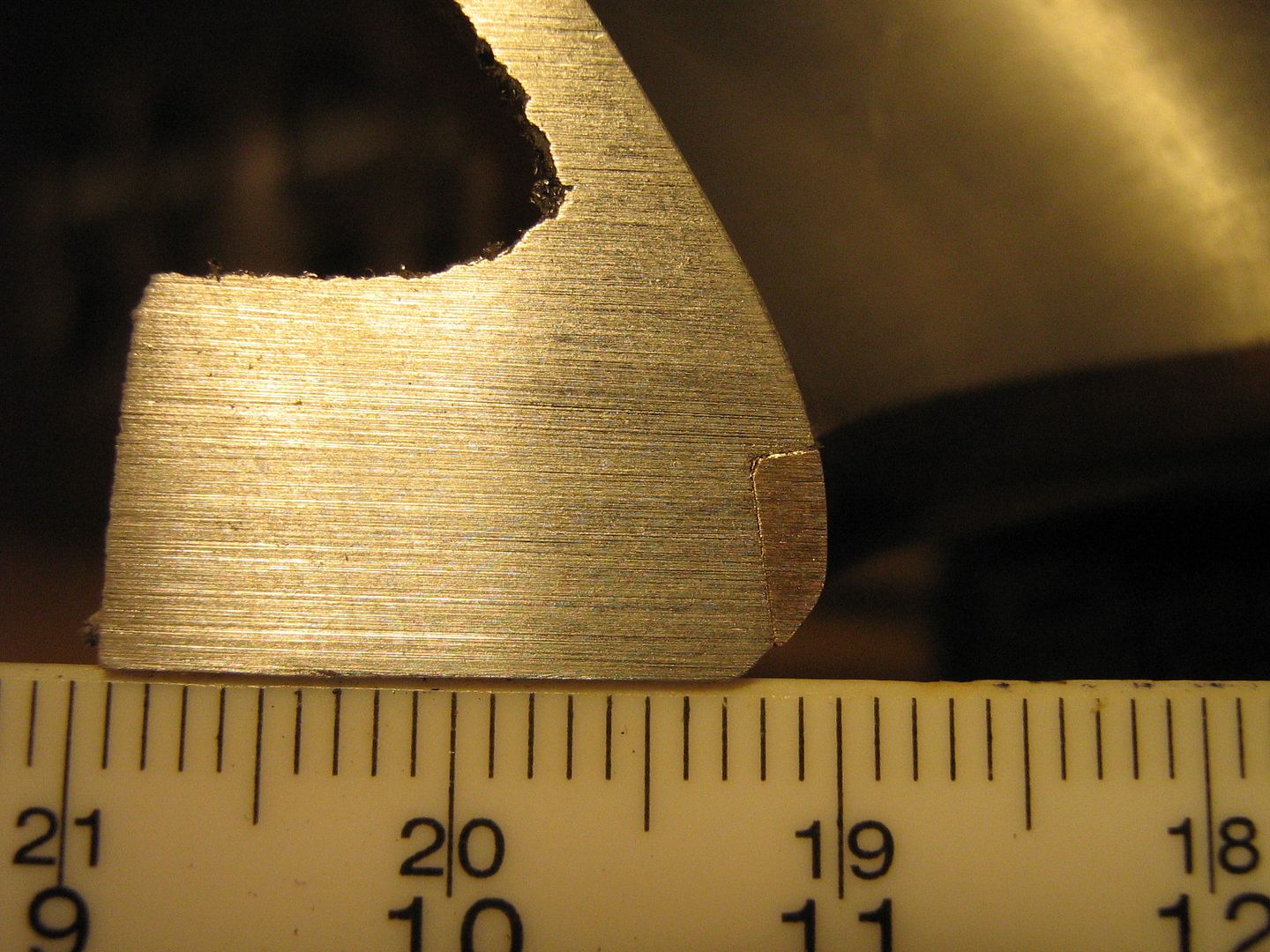

Looking at the photos of the cylinder head sections posted, the one thing that immediately caught my eye was the fairly heavy thickness of the deck wall, and how there was no apparent effort made to create a gradual transition to the thin wall section of the lower ports.

Riff raff - totally agree with all the above, the gating and riser locations also major players. I must flat mill a section, and polish it to see if there is any porosity but Im not seeing any as is. Valve stem bosses/locations are also other areas where tear can happen since they are a large mass compared to the surrounding port walls/etc but are easy enough areas to chill having said that.riff_raff wrote:Brian.G-

I've talked with the guys at ProMetal about making some pre-production EV31A magnesium gearbox sand castings. The process used to produce the molds is pretty neat, but otherwise it's basically sand casting. It's much faster and costs less than making patterns for small quantities, but it is definitely not "cheap".

When it comes to getting the best fatigue properties from a sand casting, it's all about paying attention to tiny details in the design of the casting and the tooling. I pointed out the obvious example of the abrupt transition in section thickness at the deck/port wall junction. Areas like this are susceptible to hot tears, sponge porosity, etc. that have a significantly adverse effect on fatigue properties. The problem can be partially addressed with careful use of chills, gating, etc, but the best approach is to change the casting design itself to eliminate/minimize these conditions. I looked closely at the photos for any indications of porosity or shrinkage related flaws, but it was difficult to determine if there were any due to the surface smearing created when the casting was cut apart.

Regardless, thanks for the photos. They were very interesting.

You are welcome.emc2 wrote:Brian you are the men, greatly appreciated info. =D> =D> =D>