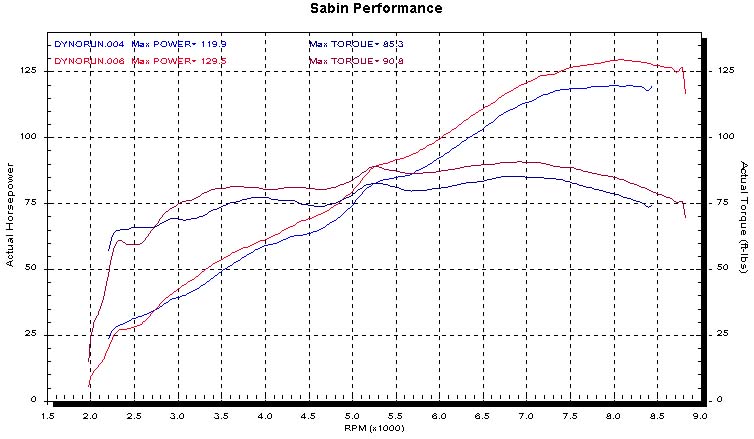

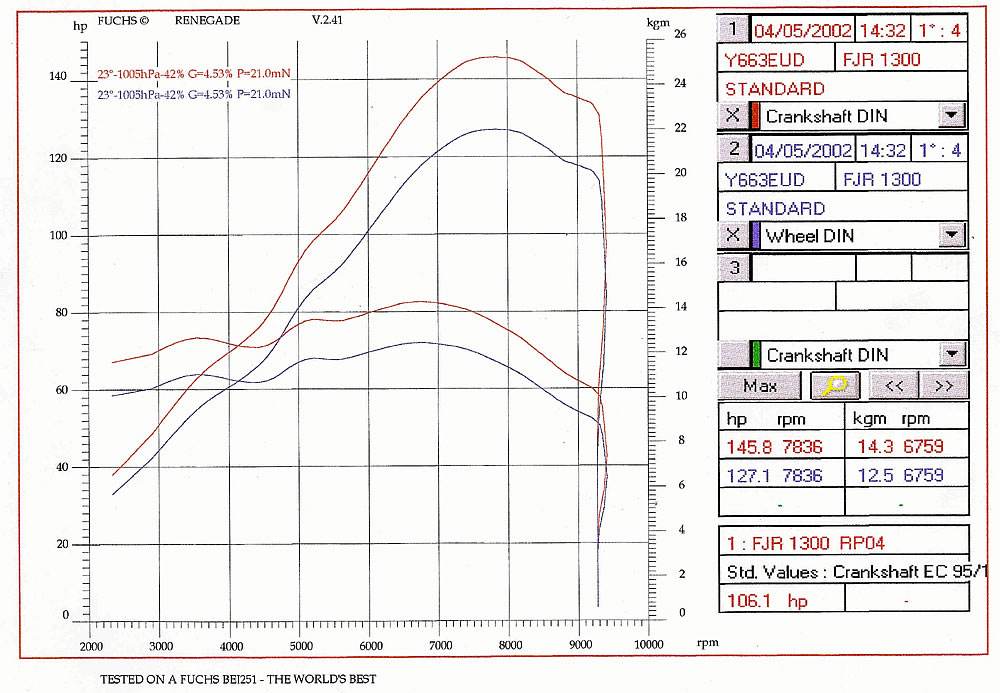

Mainly he shows hp comparisons but there are a couple of plots with torque and hp (the second and fourth ones). Doesn't make sense for the lines to cross at 7k.J.A.W. wrote: ↑14 May 2017, 13:45

P, the basic convention is to show the TQ/HP cross at the maths constant of 5252 ( where possible, most diesels wont).

But it does not alter the findings, since he is running a machine on a dyno, not a model simulation on a computer,

& his charts show the hp figures comparing curves before & after modification, rather than TQ/HP..

Three into one is more effective than people may realise, but expansions are king - if the space can be found and the narrower operating range is acceptable. Getting short headers on a triple is challenging (and OBs sacrifice any lost charge on an end cylinder in any bank for compactness) but fours permit longer headers - and shorter ex' port timing. Blair reckoned some triples had to run longer ex' duration than required for blowdown just to suit the manifolding.J.A.W. wrote: ↑14 May 2017, 13:45Yes, I have tried various pipes, inc 3-into-1, a set-up which works best when the header section is as short as practicable..

..see the Hirth triple for an exemplary unit.. & they sound very 'Ferrari V12' like, but lose out on top-end power..

..compared to well-designed 3-into-3 pipes..

The comments re larger carb and standard inlet timing make sense. The kart (Villiers 9E) I had suffered horrendous fuel stand-off off pipe. Letting milder timing create a big vacuum that a bigger carb can then feed makes sense I think. Extreme timing at low rpm just blows it all out. On readmission, it has picked up three times the required fuel!

Faffing about with the Zenoah (admittedly low delivery ratio and conservative timings), it was quite a shock to see just how late before the inlet is opened. No fuel stand off there though.

With your Kawa motor though, isn't it just pumping it back out at lower rpm as opposed to any pulsation effects. (There's no real harsh pressure differential there around TDC to create a pulse. Vacuum pulse on port opening - very different though!)