I thought it would be an interesting exercise to attempt to calculate the piston thermal and mechanical loads based on the information available on these engines.

The TJ was Cosworth's last F1 V10 having been introduced in 2003 and replaced in 2006 by the CA V8. Towards the end of its development it reached 19,000 RPM and a peak power of about 920 hp. Engine life was 800-900 km.

The piston is of a fairly standard box bridged construction and made of A2618 which has been used in Cosworth pistons since the DFV. The billet is forged, then machined. The undercrown is shot peened and polished while the crown is simply just polished. The skirts are Xyalan (1000s series) coated. DLC coatings were experimented with but the processes for applying DLC to aluminium were still in their infancy at the time and usually resulted in poor substrate adhesion or reduction in strength due to the high temperatures required.

The exhaust valve pockets break out into the top land, while the intake pockets are fully contained within the crown and form a thin wall at the closest point to the top land. As the TJ did not have compound valve angles the crown dome is fairly clean.

An interesting feature is the small pocket on the under crown that matches the intake squish land.

The pin bore ribs are slightly angled, presumably to direct the load towards the T rib. This sometimes has the disadvantage of reducing the ring belt support, particularly for larger bore pistons. By contrast, the 98 mm diameter CA piston had straight pin bore ribs aligned with the T ribs.

The ribs blend nicely into the crown with approx. 4 mm rad fillets.

The top ring land is relatively high. There are no gas slots - the gasses energizing the top ring have to travel through the clearance between the ring and the groove. Below the top ring there is a standard vee shaped accumulator groove. The oil control ring groove contains 8 oil drain holes.

The piston skirt has an ample relief at the bottom - this is evident in the wear pattern since the xylan coating is almost untouched.

The rod thrust faces have shallow angled grooves machined to provide lubrication. These grooves break out into small axial relieves in the pin bore.

The piston pin runs straight into the aluminium bore.

Each pin bore half has edge relieves at both sides. Again this is evident from the dark contact marks which are offset away from the edges.

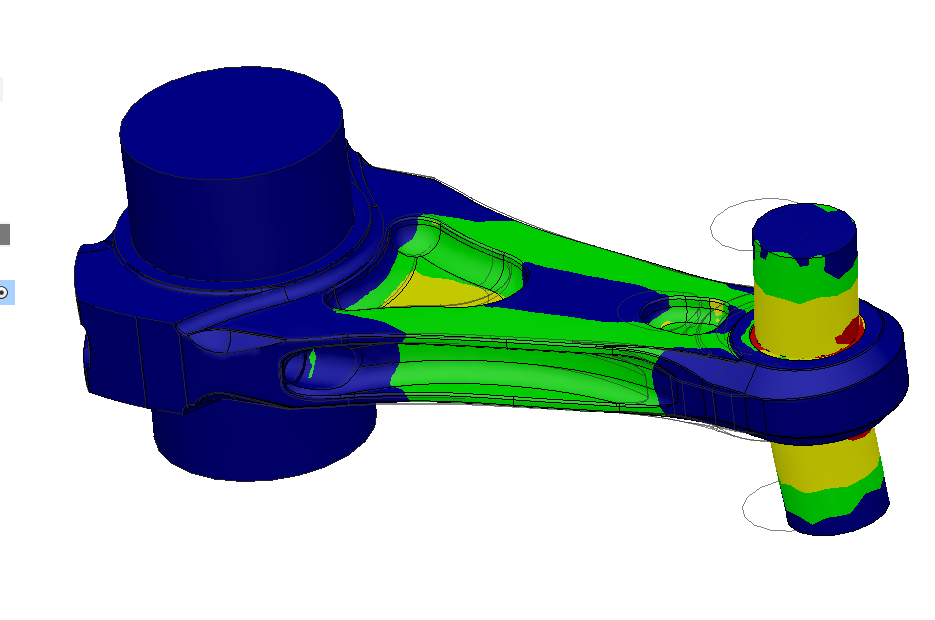

To be able to analyze the piston I created a rough but hopefully representative CAD model.

There is a slim chance I might be able to CMM it at work next year but for now it will have to do.

Some general dimensions in mm:

Next on the list was to create an engine cycle simulation model to estimate the cylinder pressure, gas temperature and crown heat transfer coefficient. This was achieved by building a single cylinder model in a free version of Lotus Engine Simulation available online.

The objective was to tweak the model in order to achieve a peak cylinder pressure of around 100 bar as this was the maximum suggested by Honda at peak torque during the V8/V10 eras. The simulation used an unmodified Vibe curve for heat release and Annand's correlations for HTC prediction.

The cycle average temperature and HTC were used to define the boundary conditions in a thermal FEA.

For cooling, the piston spray velocity was calculated by solving Bernoulli across the nozzle (assuming 0 velocity within the oil gallery) for 8.5 bar oil pressure. The nozzle velocity obtained was 45.8 m/s. This might seem high but Cosworth have stated that the CA piston (42.4 m/s peak velocity) could outrun the spray at peak engine speed since the engine was running 1 bar lower oil pressure.

The calculated spray velocity was used to compute Re for use with a jet HTC correlation (Jigi and Dagn in this case). For piston surfaces not directly sprayed the flat plate correlation was used taking mean piston speed for Re calculation.

As such the thermal boundary conditions are:

These were used in an Ansys FE model to predict temperature distribution. Since I ran most of the simulations at home on the work laptop I had to keep the size of the models very small. As such I was forced to use a piston quarter model, even though the piston is not exactly symmetric about the pin axis.

Temperature distribution in °C is predicted to be:

The cylinder pressure trace was used to calculate piston loads at 19000 RPM over an engine cycle. The maximum vertical, minimum vertical and maximum lateral (thrust) loads were extracted from the loading history and used for FEA and fatigue analysis.

The piston load history is shown below:

At peak cylinder pressure a part of the load is relieved by the piston inertia acting in the opposite direction. This is commonly referred to as inertia relief. At this particular point, reducing either the piston mass or the engine speed would results in an increase in piston load. It is again known that when FIA imposed engine speed restrictions during the V8 era some manufacturers (Cosworth included) had to redesign their piston for this particular reason.

Notice that the 100 bar cylinder pressure given by Honda was given at peak torque, while I have used it at peak power. For a proper piston analysis all relevant engine speeds with the correct pressure trace should be represented.

As a consequence, the piston loading for these calculations will be over-estimated. This will be obvious when looking at the fatigue results later.

As a reference for how much the cylinder pressure can be expected to decrease between peak torque and peak power engine speeds I've estimated that the CA piston only saw 70 bar pressure based on piston loads published by Cosworth in RET.

Some FE results of pin bore contact pressure are shown below.

Contact pressure distribution during peak cylinder pressure at 19000RPM (just after TDC, power stroke):

Contact pressure distribution during maximum vertical load at 19000RPM (TDC, exhaust stroke):

Maximum tensile stress:

Maximum compressive stress:

Maximum compressive stress at peak piston thrust:

The stress history was brought into nCode DesignLife for fatigue calculations.

Assuming that the engine operates at an average speed of 15000 rpm for 900 km the required life of the piston is 1e7 cycles. In the plot below black denotes failure at fewer than 1e7 cycles.

In reality the engine would operate at full load/ full speed for maybe half of its life. The fatigue prediction is overly conservative since I do not know the actual duty cycle and I have over-estimated the firing loads. It is interesting that all traditional piston failure areas are highlighted: the pin bore, the bore strap, valve pockets and the blends between ribs and crown.

I have left out a a fair bit of data in order to make this more accessible but I am open to go into more detail if requested.

Time permitting I will have a stab at doing something similar with the rod from Brian.