I am new to the forum and have a crank related oiling question for anyone willing to chime in. I'm getting into my 3rd custom single cylinder roadrace motorcycle design and this one will have a custom crankcase/transmission assembly mated to a Ducati Panigale 1299 cylinder head, piston, and wet liner. I've done head/crankcase transplants before with good power and so-so reliability results so hope this build of a dedicated bottom end will increase the reliability aspect, and of course allow some more power to be squeezed out.

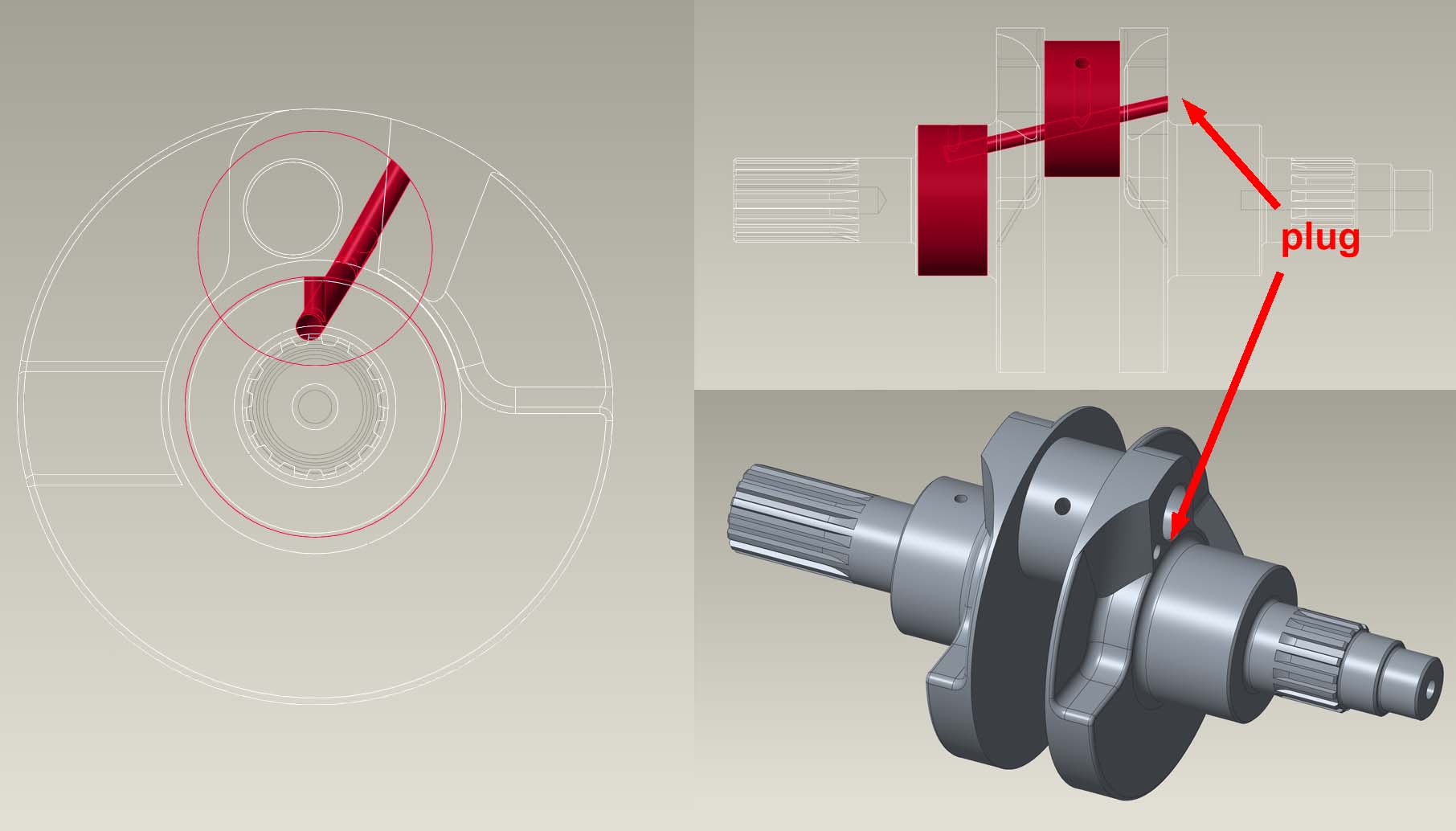

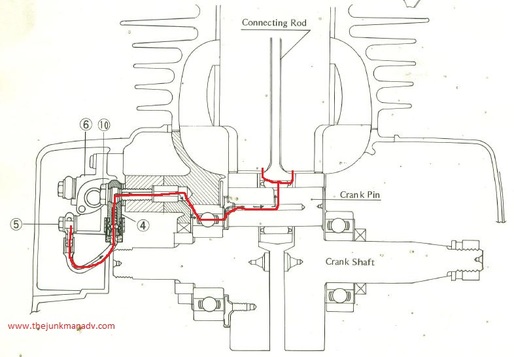

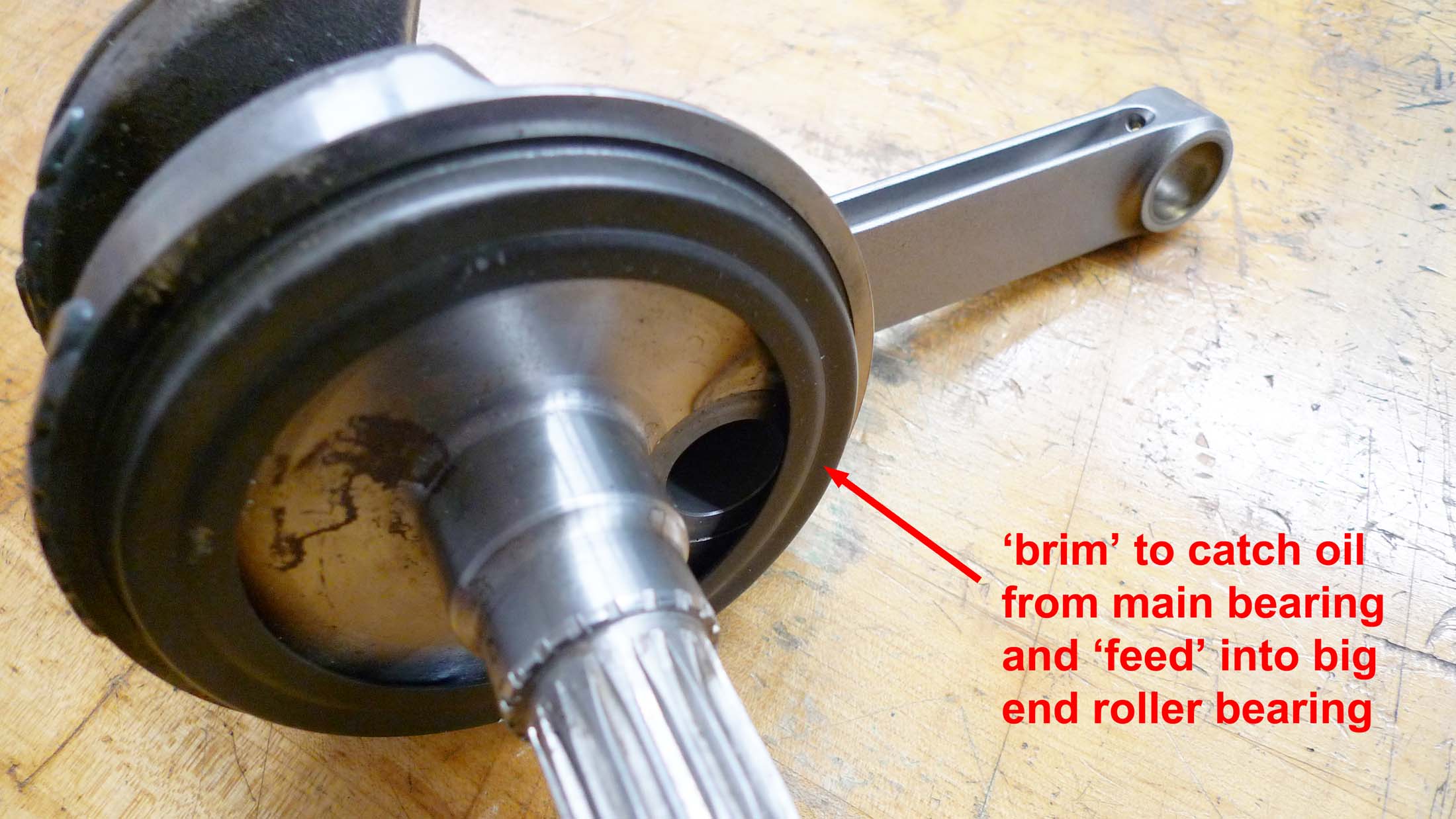

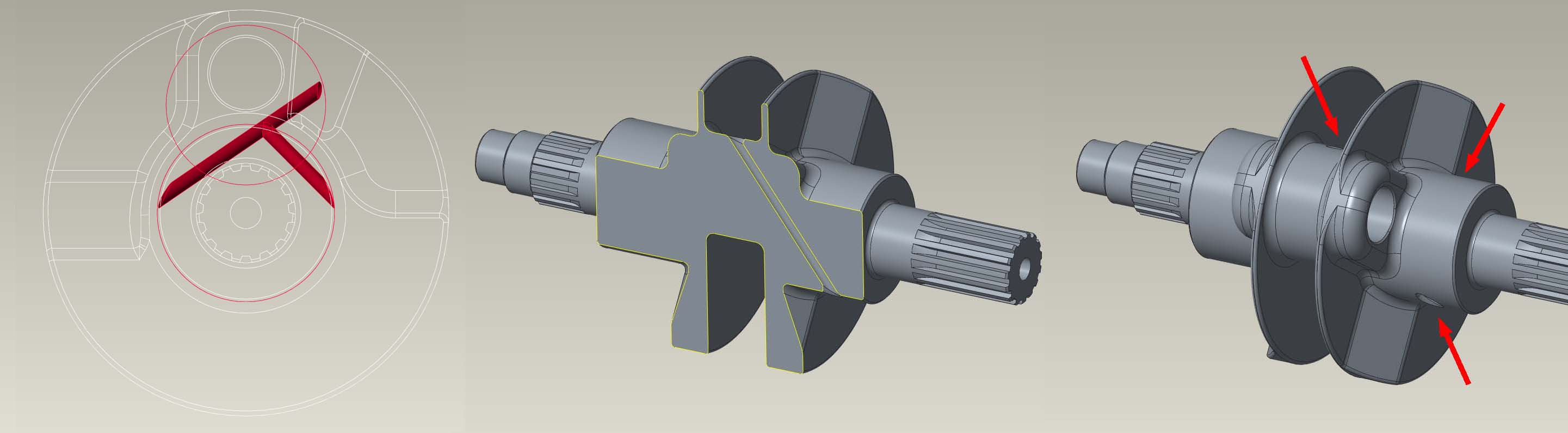

Most stuff is straightforward but one area I have less experience in is plain bearings/crank oiling. The crank will have plain rod and main bearings. I want to keep the overall engine narrow, the crank short, and the oiling system simple. To this end I want to use a mains-to-rod oiling system instead of feeding the rods through the crank nose as Ducati has done for a long time. This eliminates the need for an oil line through the side case and into the end of the crank and tidies up design, but I don't want to do it at the cost of oiling issues. Both mains would be fed directly from oil passages in the block. I would feed oil from the non-primary drive side using a grooved main bearing and a 'straight shot' oil hole to feed the single rod to an exit location forward of TDC/TDC. The oil hole can be skewed so that it's effective radius from the crank axis does not decrease that much to minimize its fight against centrifugal forces. I can have two feeds at 180 on the crank main bearing surface to ensure continuous flow. The engine turns 12krpm max.

Do you think this would provide sufficient oil to the rod? The section shown is through the oil hole axis and the front view shows the hole trajectories relative to the two bearing journal surfaces. I also use a large through hole at the big end for stress reduction instead of the Klose relief.

Thanks for any input.