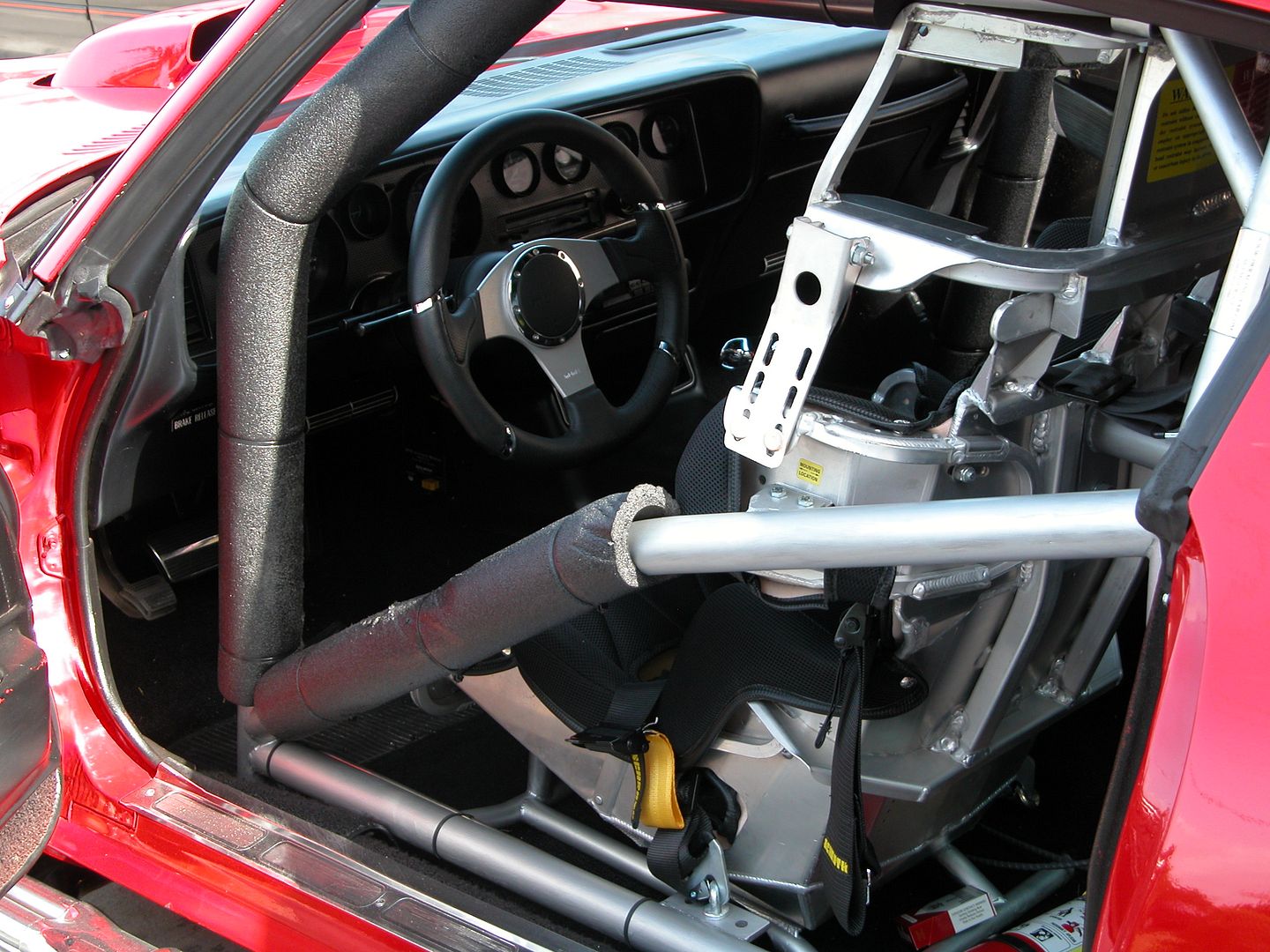

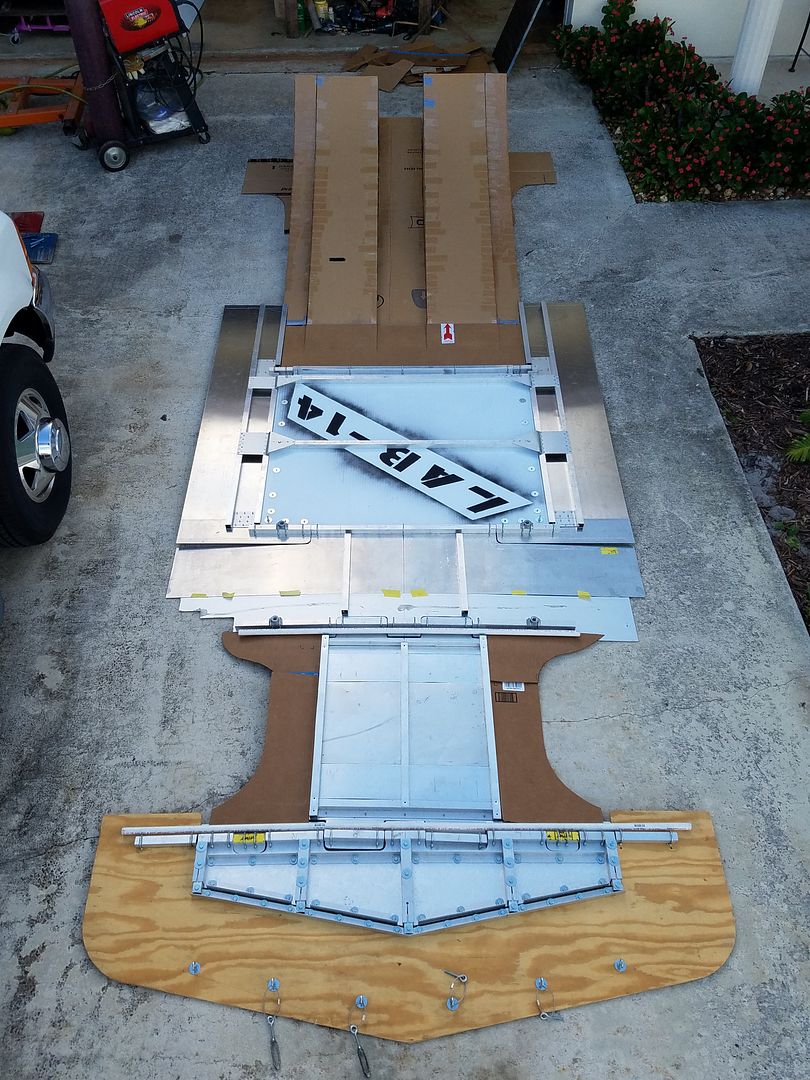

I've been working on an under tray for one of my own cars and figured I'd share it here since there seems to be quite a few people here with an interest in race car aerodynamics. For me this is a learning experiment, not trying to "win" anything. The car gets used for road tracks, mile land speed race events, drag race test and tunes, and driven on the street. Road courses are my favorite activity and the tray system design I'm currently building will hopefully decrease lift/increase down force. You could think of my car as something like a (really old) time attack car or hill climber but with no rules to adhere to.

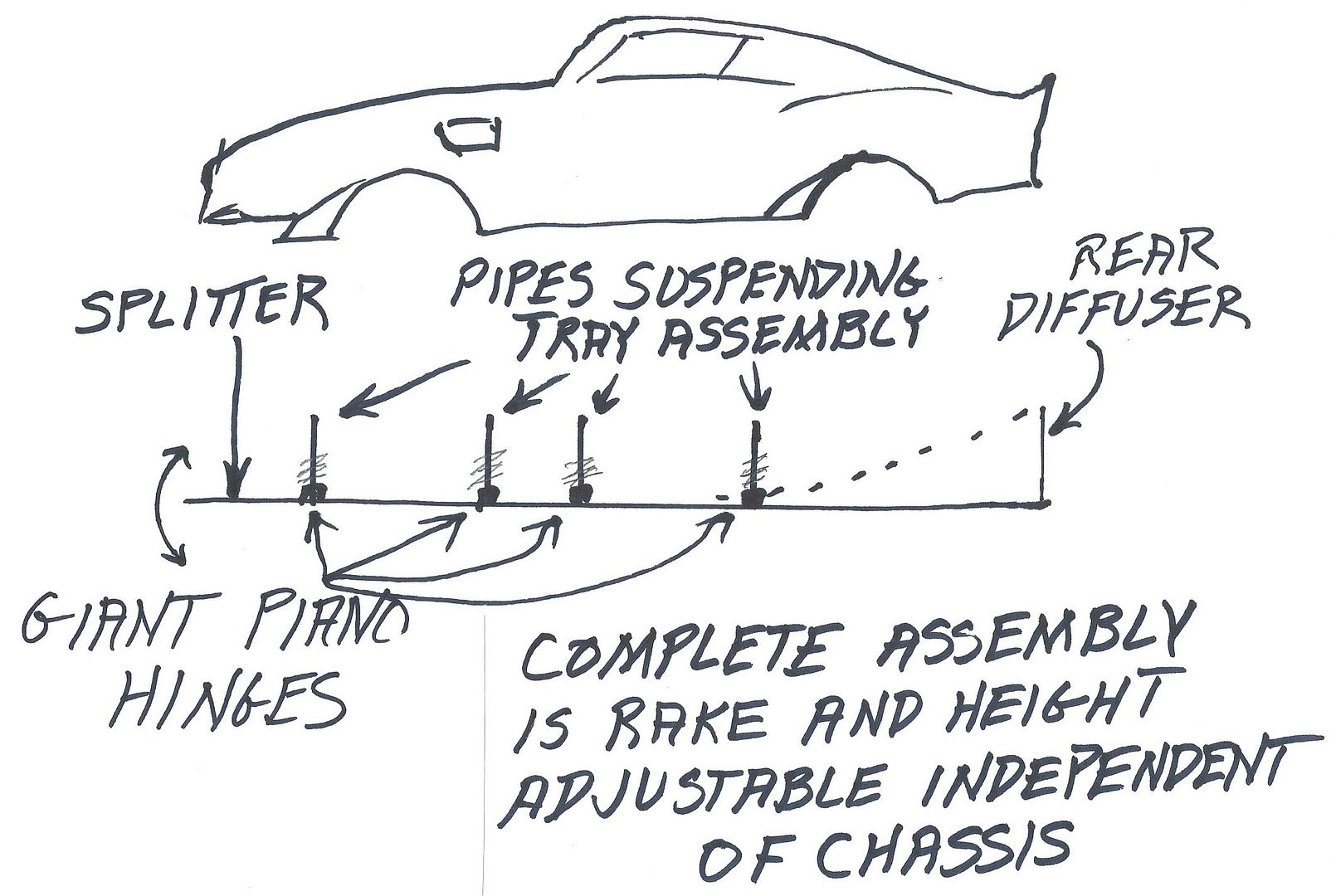

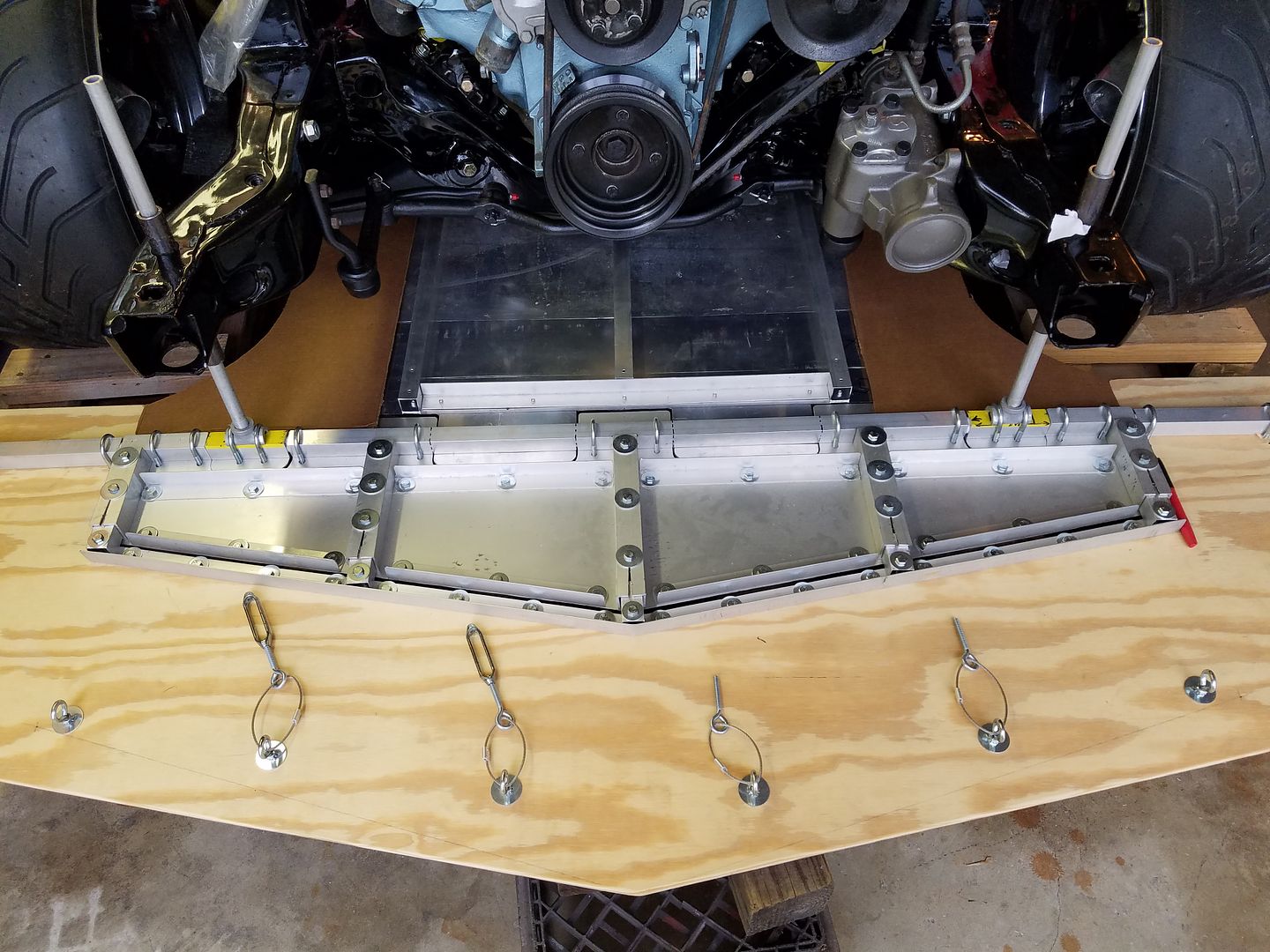

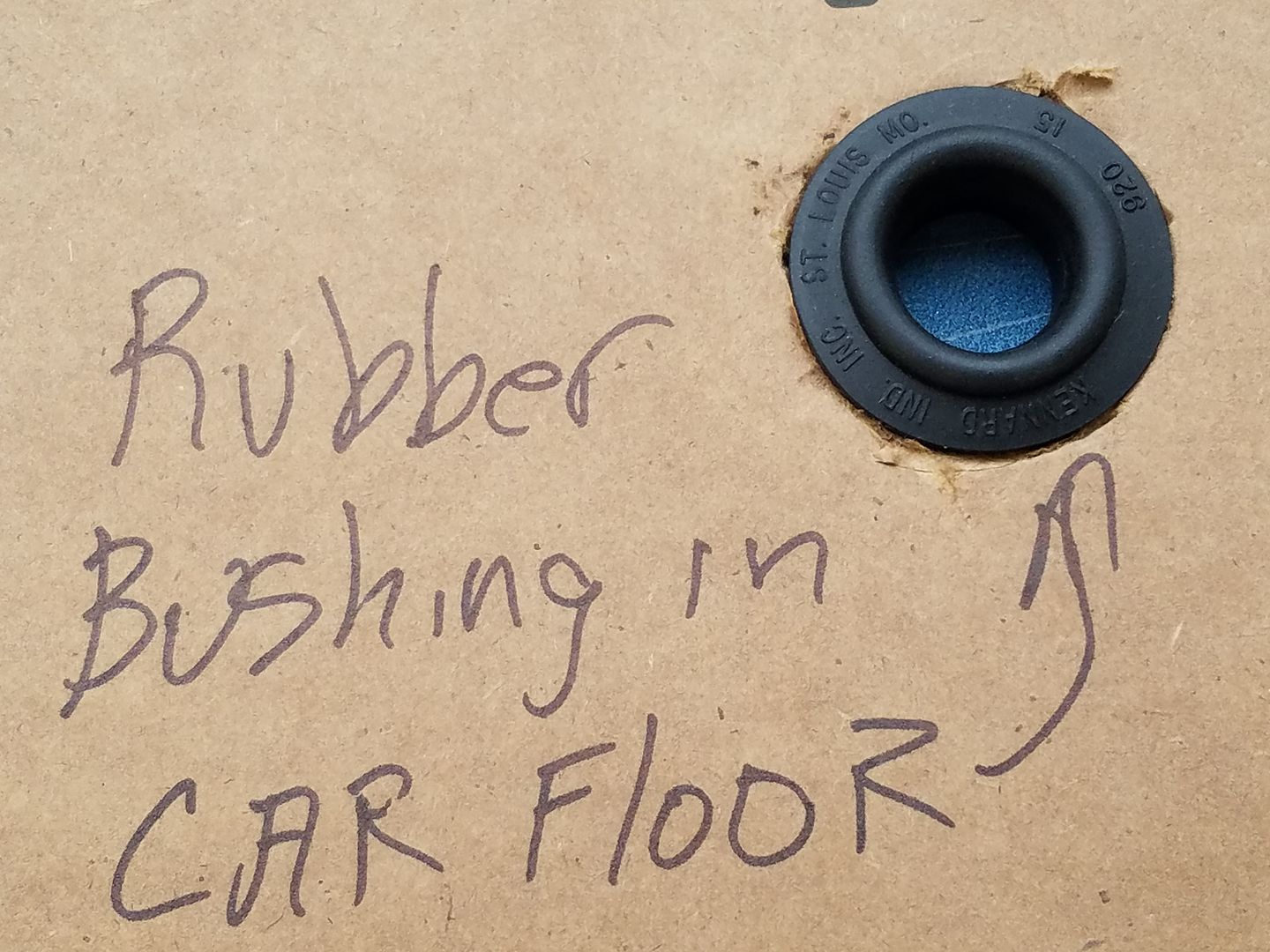

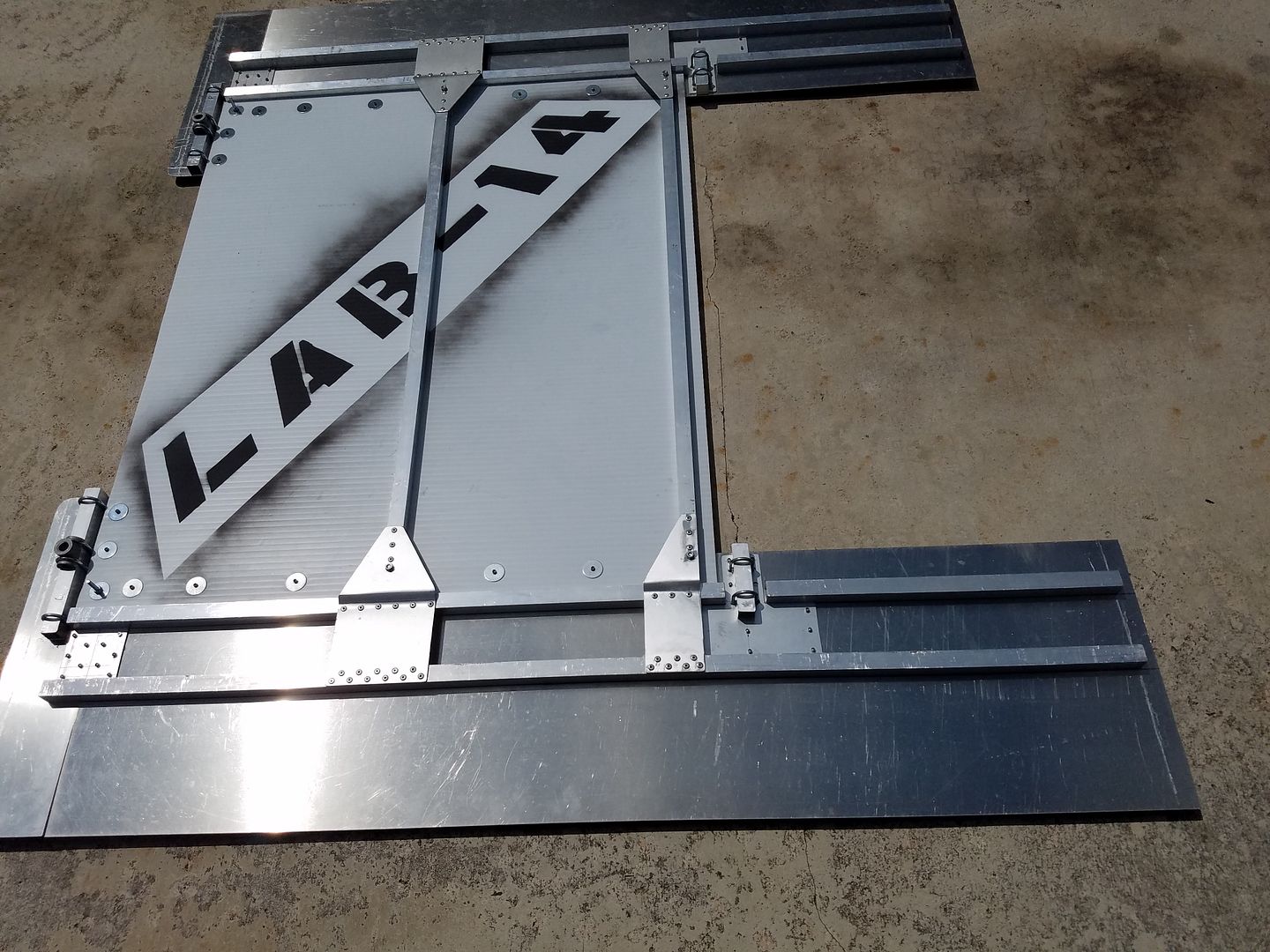

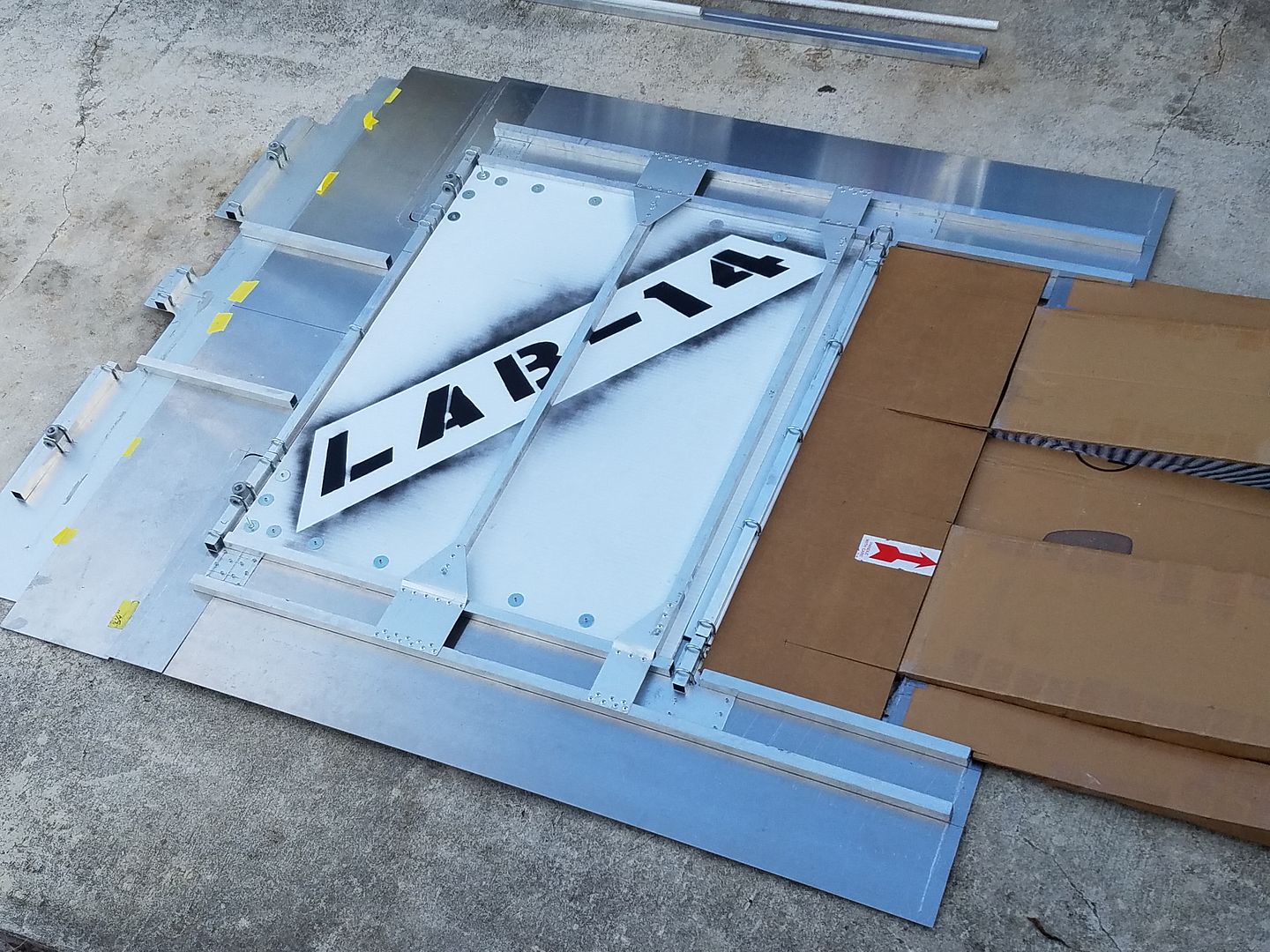

There's a couple twists to what I'm doing that are different than the typical race car set up. The splitter is hinged to be able to be used as an expanding or contracting diffuser, the whole tray system is suspended from the car, and the space between the tray and car body is open on the sides with an additional opening in the center of the rear diffuser.

While there's a lot of folks here with the knowledge and skills to model, mesh, etc. and then run CFD programs to determine a more optimal design, I can't. However in less time than it would take me to learn one step of that process I can fabricate a crude under tray system to test. And since I'm not trying to win anything but could learn a lot I decided to just jump in and build my vision.

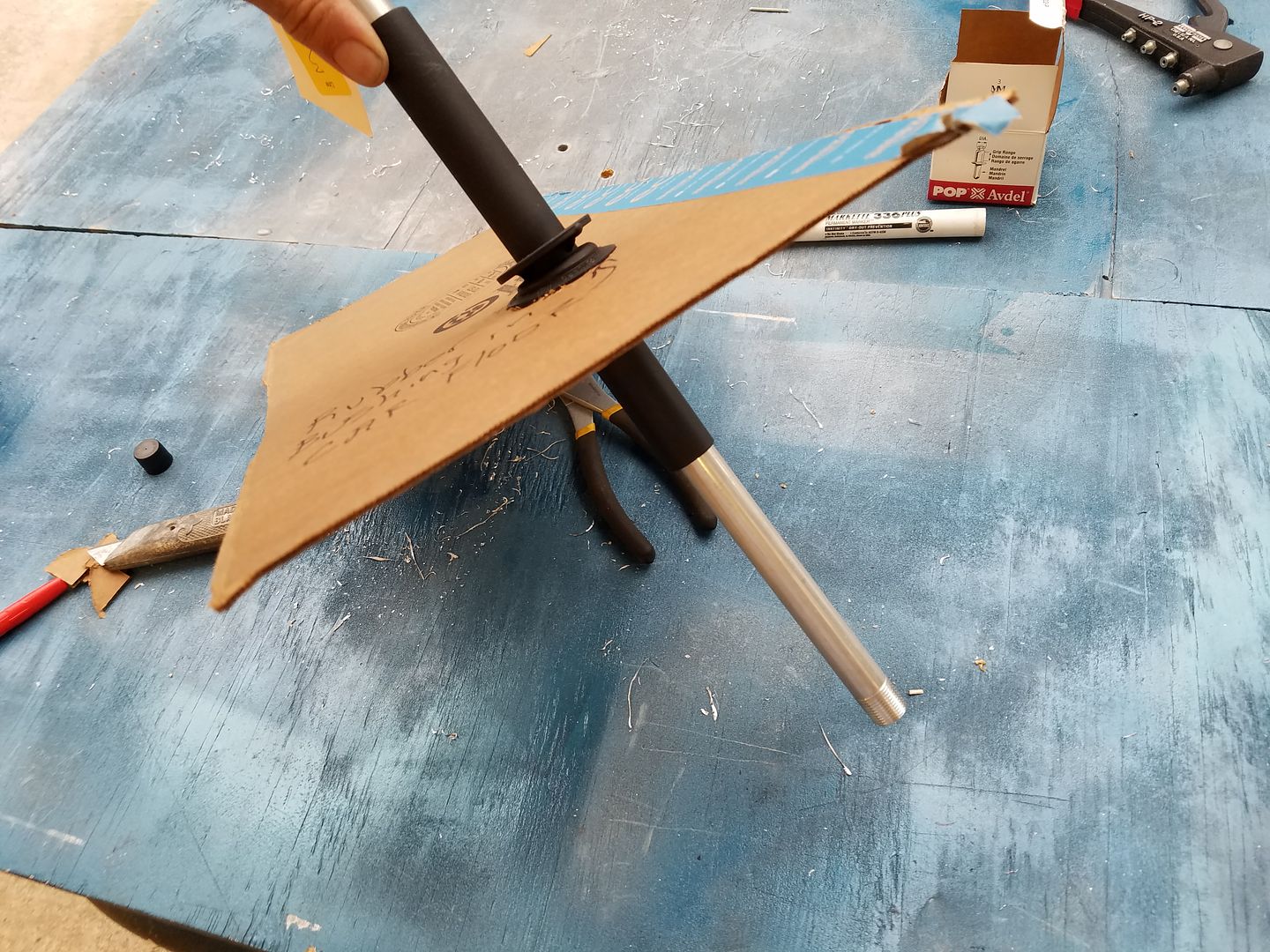

So I'll end this first post with a couple pics of the car I'm building the contraption for and a quick sketch of the concept. I'm getting old, downsizing, and sold my drafting table etc. several years ago so I can't even post a Newey type drawing.