And do we know if any teams use them ?... It would seem that having the ring tight to the bore on the power stroke , but looser on the other strokes would save a lot of friction.

Rob

We used this idea way back on dragster engines.riff_raff wrote:The piston compression ring gas porting shown in your pictures is that used on long stroke drag race engines that have far higher linear acceleration rates than the current 12krpm short stroke F1 engines. It is used to prevent ring flutter, but does not reduce friction losses from the compression rings.

I read about gas ported pistons on this Reher Morrison Racing Engines page..riff_raff wrote:The piston compression ring gas porting shown in your pictures is that used on long stroke drag race engines that have far higher linear acceleration rates than the current 12krpm short stroke F1 engines. It is used to prevent ring flutter, but does not reduce friction losses from the compression rings.

One reason to machine a larger bore clearance on race engines gg.gruntguru wrote:All piston designs rely on gas pressure behind the top ring to hold it against the bore. Gas ports only become necessary if piston acceleration near TDC holds the top ring too tightly against the top land - blocking the access of combustion gas to the back of the ring.

Have you any more details as to why Brian?Brian Coat wrote:I believe this type of *vertical* gas port is used on Pro Stock and NASCAR Pistons but not TF/FC/TA/TAFC.

These are unblown gas/petrol engines with big bores (typically ca. 110 mm IIRC).

Dykes rings are similar to gas porting in the sense that they can still make use of gas pressure when piston acceleration is holding the ring tight against the top land.Brian Coat wrote:I think the really powerful engines in drag racing go for dykes rings - friction and wear not are the over riding concern in those classes - they just need to SEAL in those vast pressures (top fuel BMEP is over 100 Bar!!)

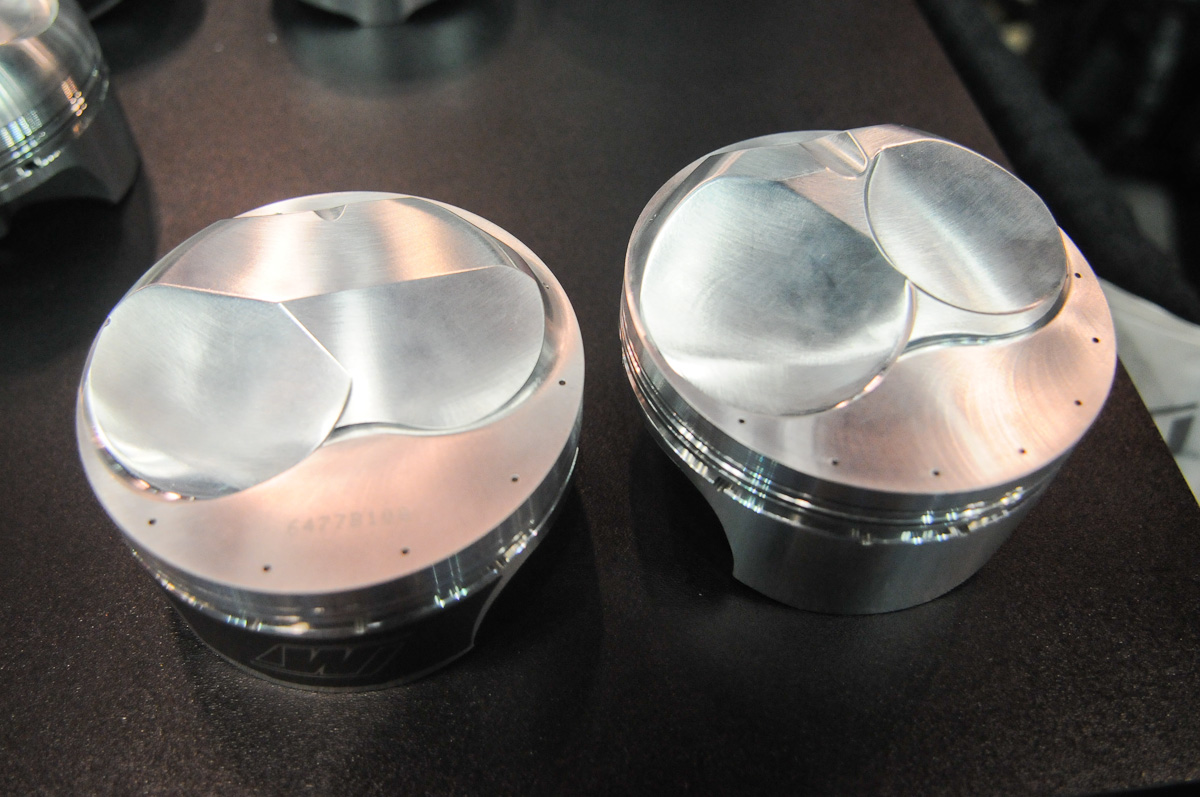

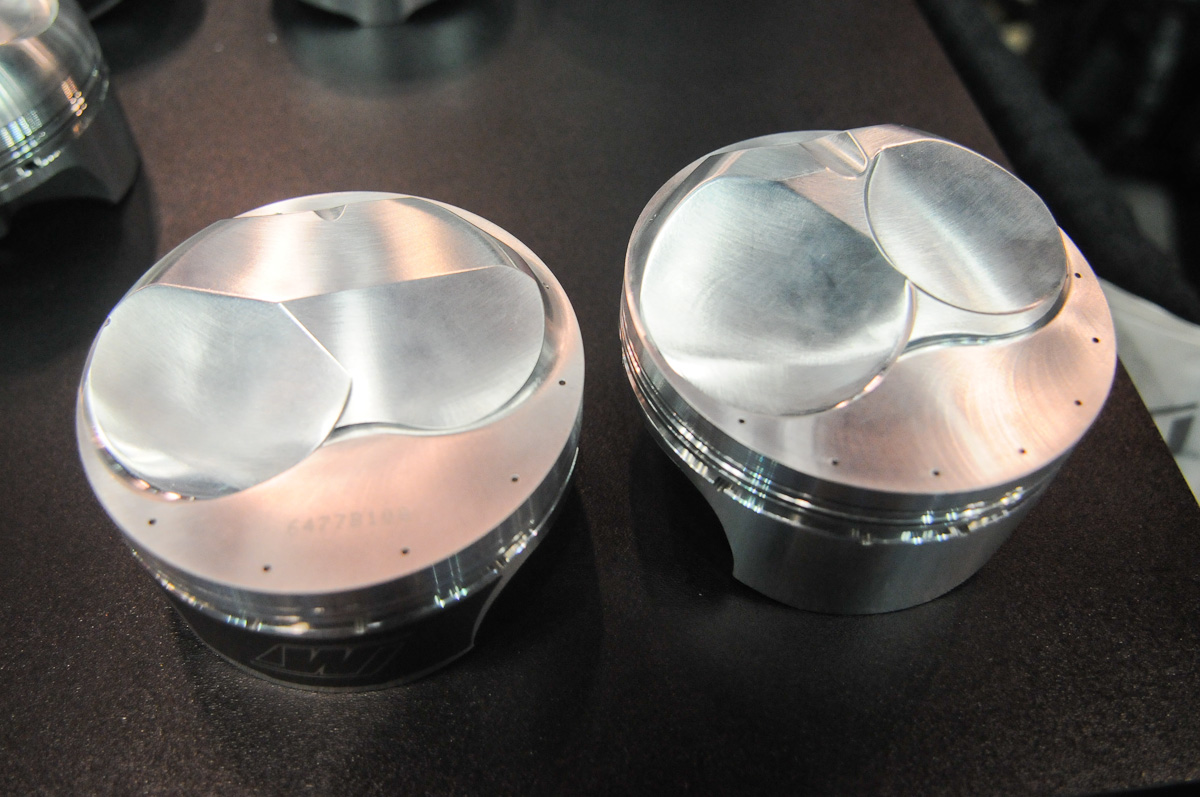

Actually, piston rings rely on installed preload to ensure the optimum amount of radial contact pressure for most of an engine cycle. The aspect ratio of a piston ring cross section (width/height) is also important, as this will affect the performance of the ring in terms of friction and dynamic flutter. As the image below illustrates, the reason compression ring gas porting becomes necessary is when the normal combustion gas flow path thru the annular gap between the piston top land and bore surface is too restrictive to allow sufficient gas pressure levels in the groove space above/behind the ring to ensure adequate sealing and prevent dynamic flutter. The gas ports used on drag race pistons simply provide a more direct/efficient flow path for the combustion gas to the groove space above/behind the compression ring.gruntguru wrote:All piston designs rely on gas pressure behind the top ring to hold it against the bore. Gas ports only become necessary if piston acceleration near TDC holds the top ring too tightly against the top land - blocking the access of combustion gas to the back of the ring.