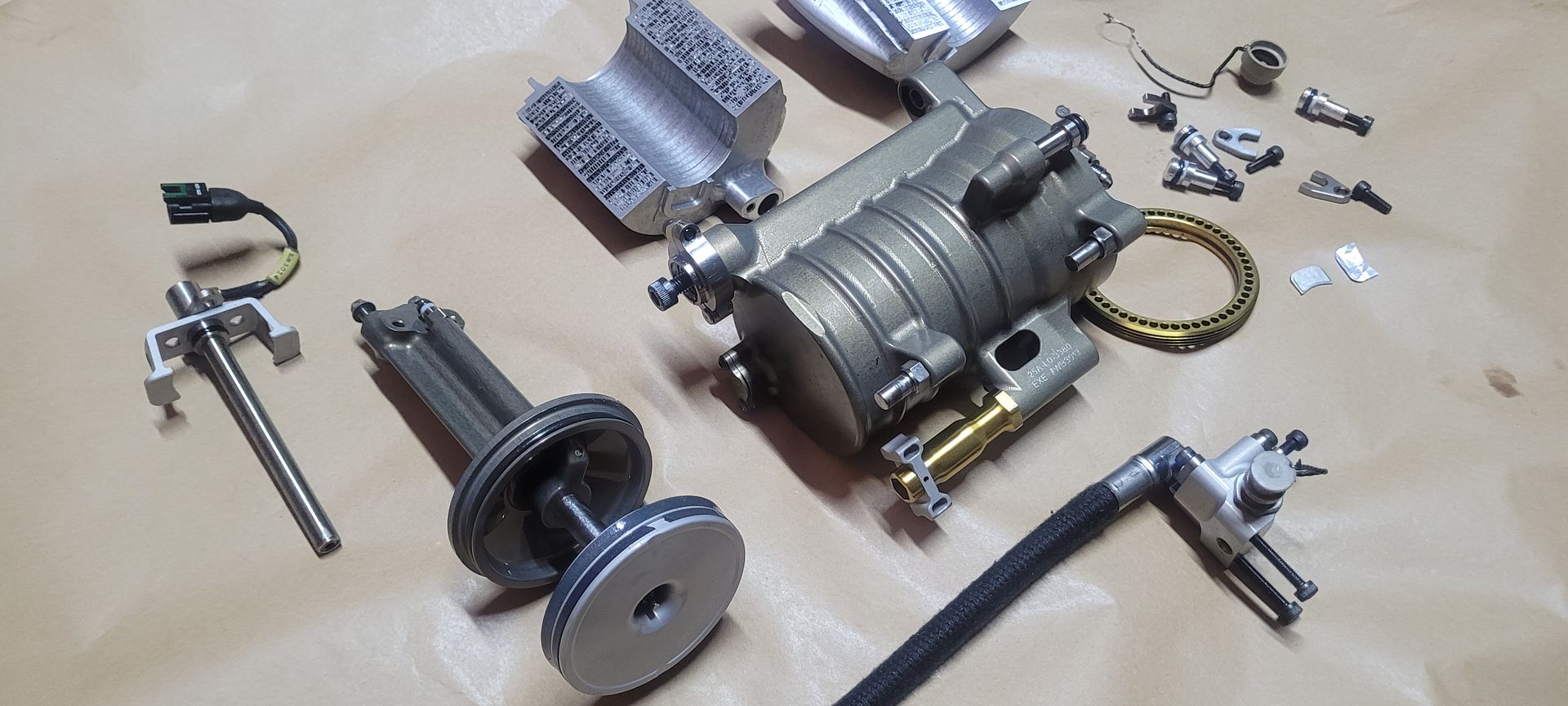

In this thread I will be unlocking a few secrets hidden within this part - The F1 Hydraulic Oil Heat Exchanger and Accumulator, mainly its construction, operation, and some other features.

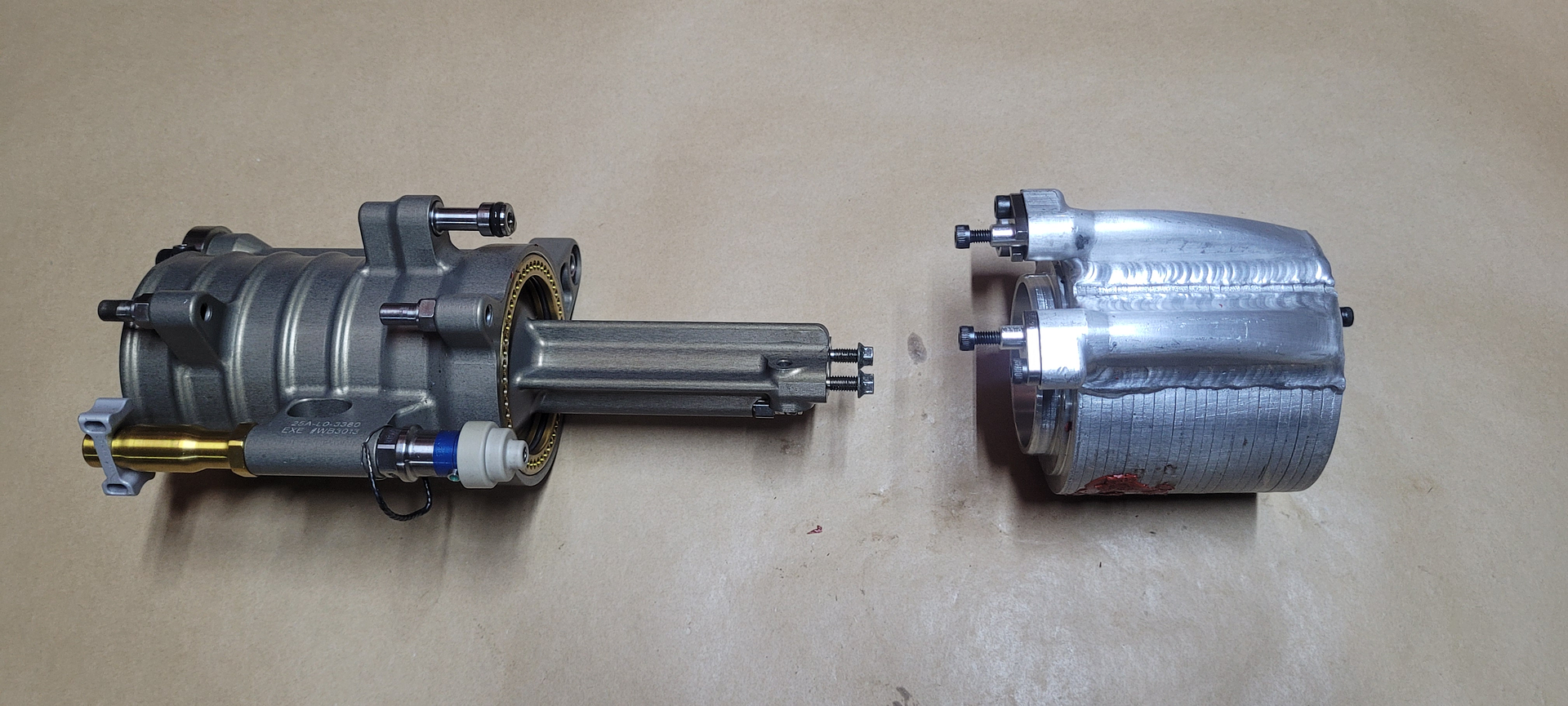

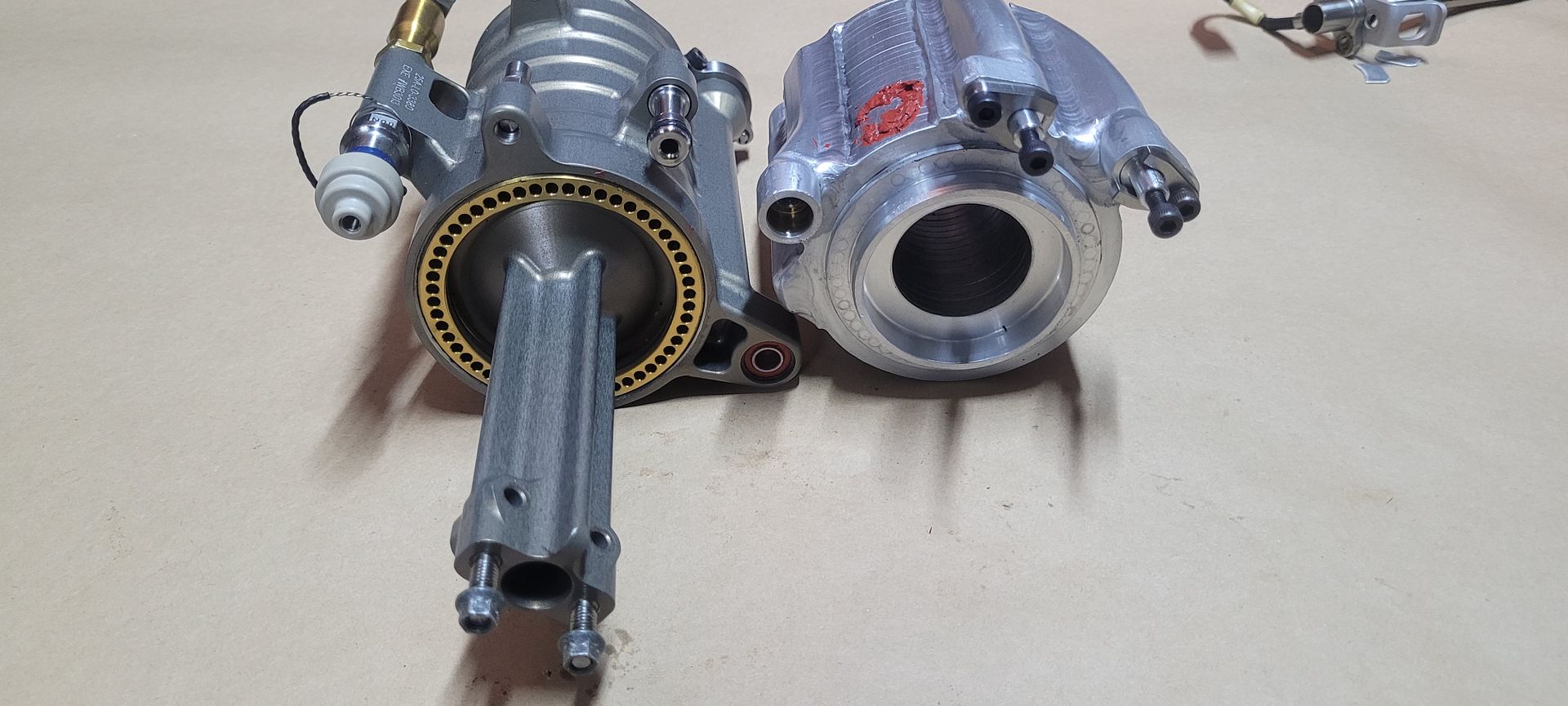

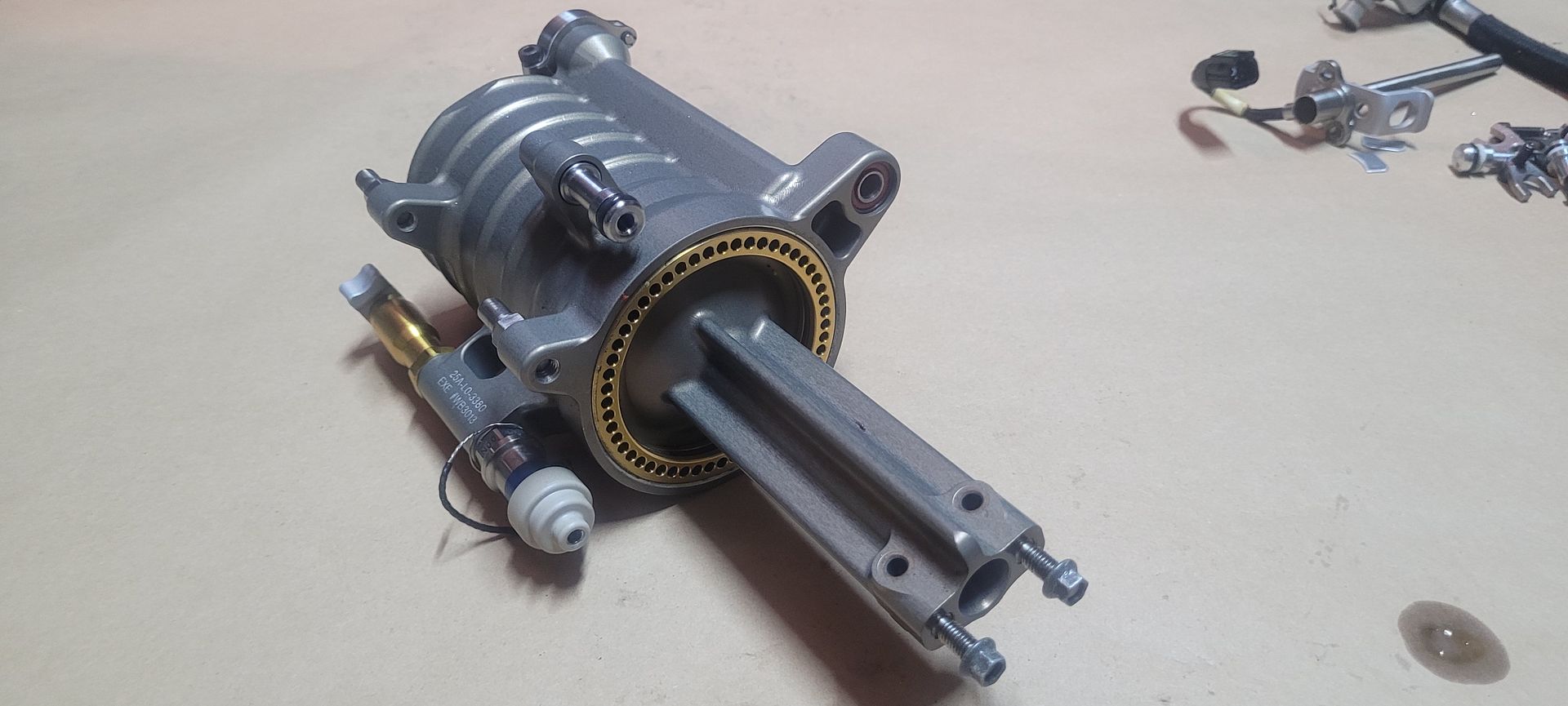

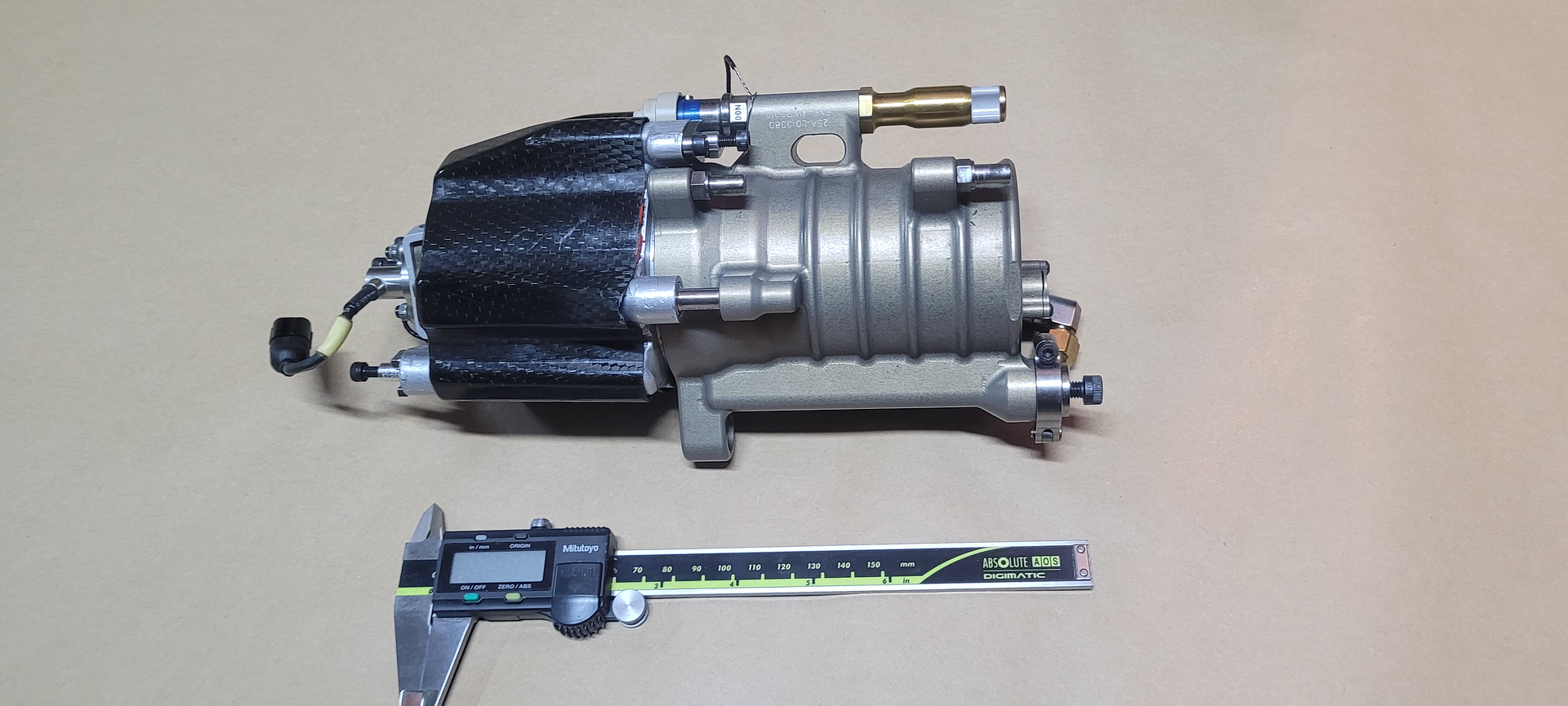

The part in question is from the Williams BMW Fw25 2003. Hard to believe this part is now 20yrs old - it still looks like it was manufactured yesterday. The part was bought blind not fully knowing what it was, the advert had two pictures and it was described as ''Pump''. Initially from the add it roughly resembled a fuel collector combined with the high pressure fuel pump but in the end it turned out it wasn't a pump at all. It is however a hydraulic oil to water heat exchanger with an integrated piston type accumulator.

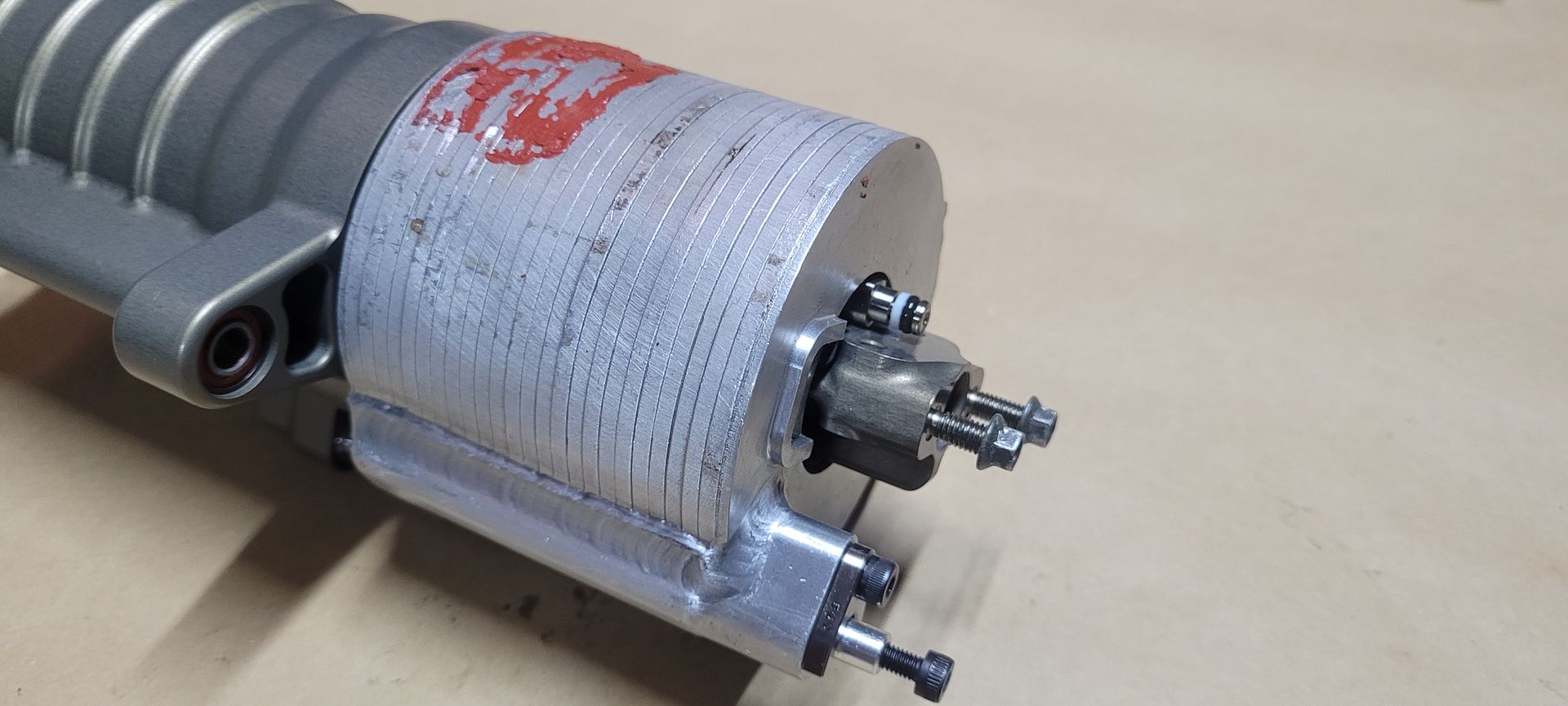

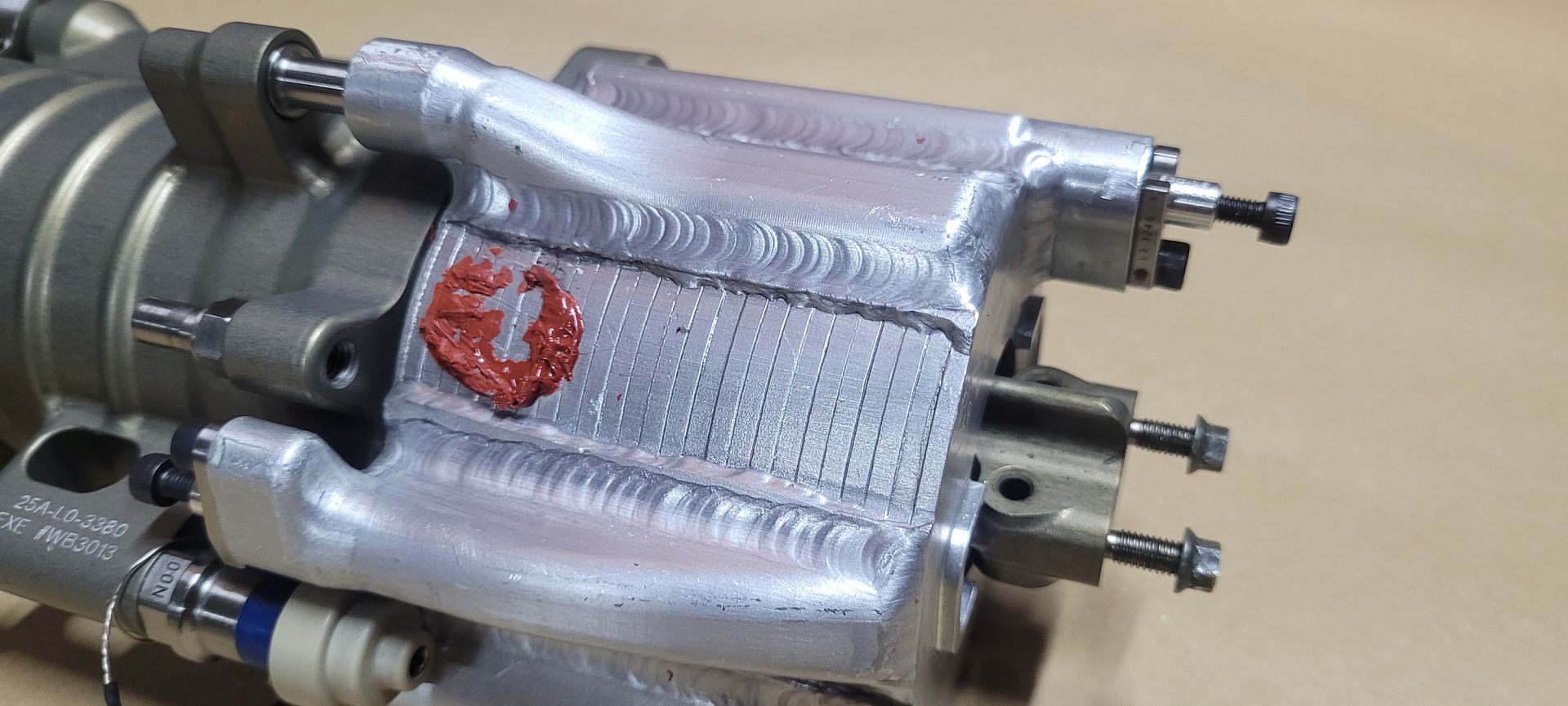

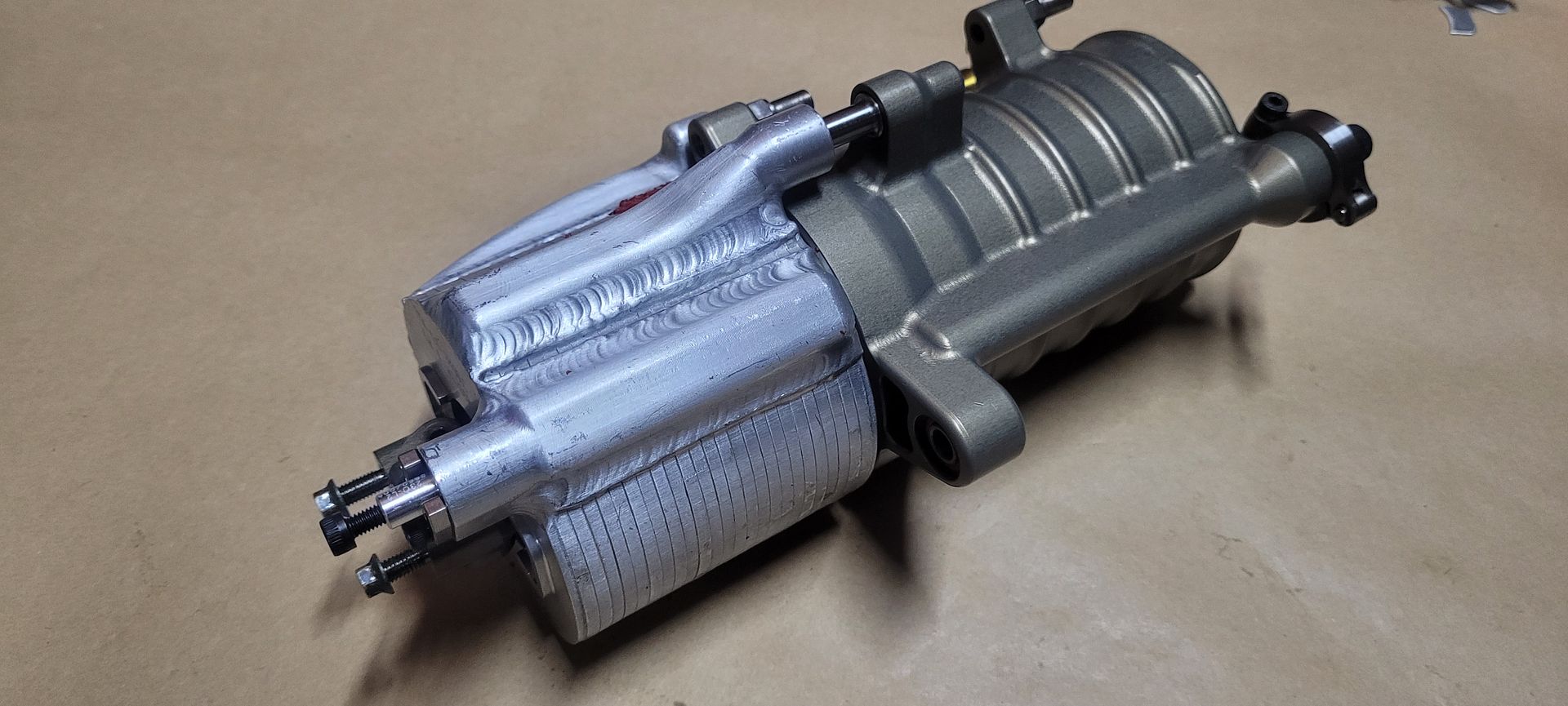

So with that in mind lets push onto the part in hand, it is a beautifully made part as you can see,

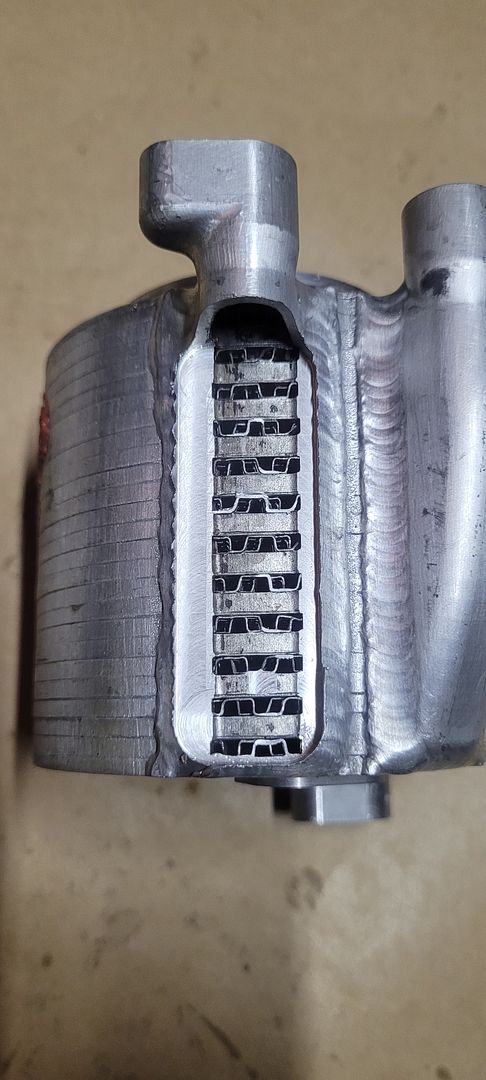

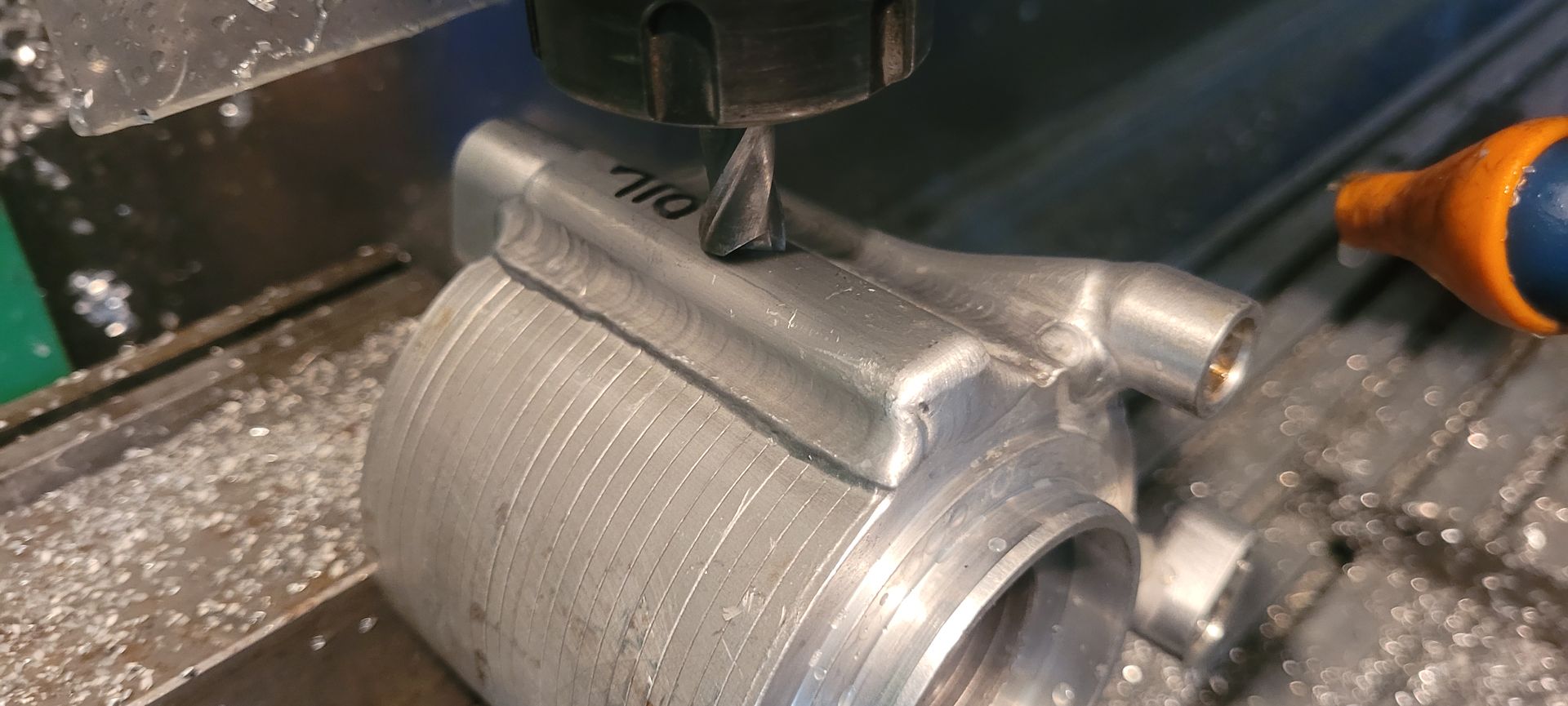

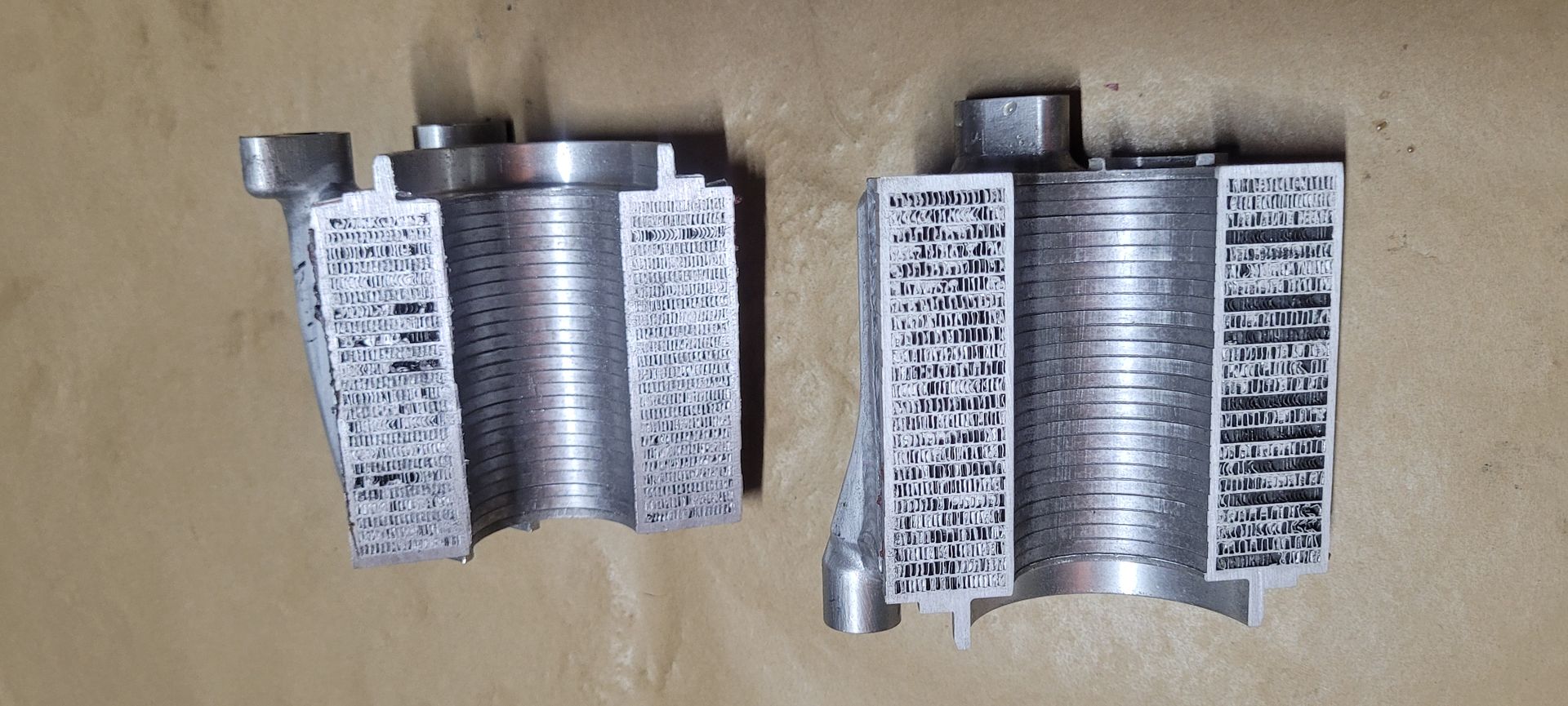

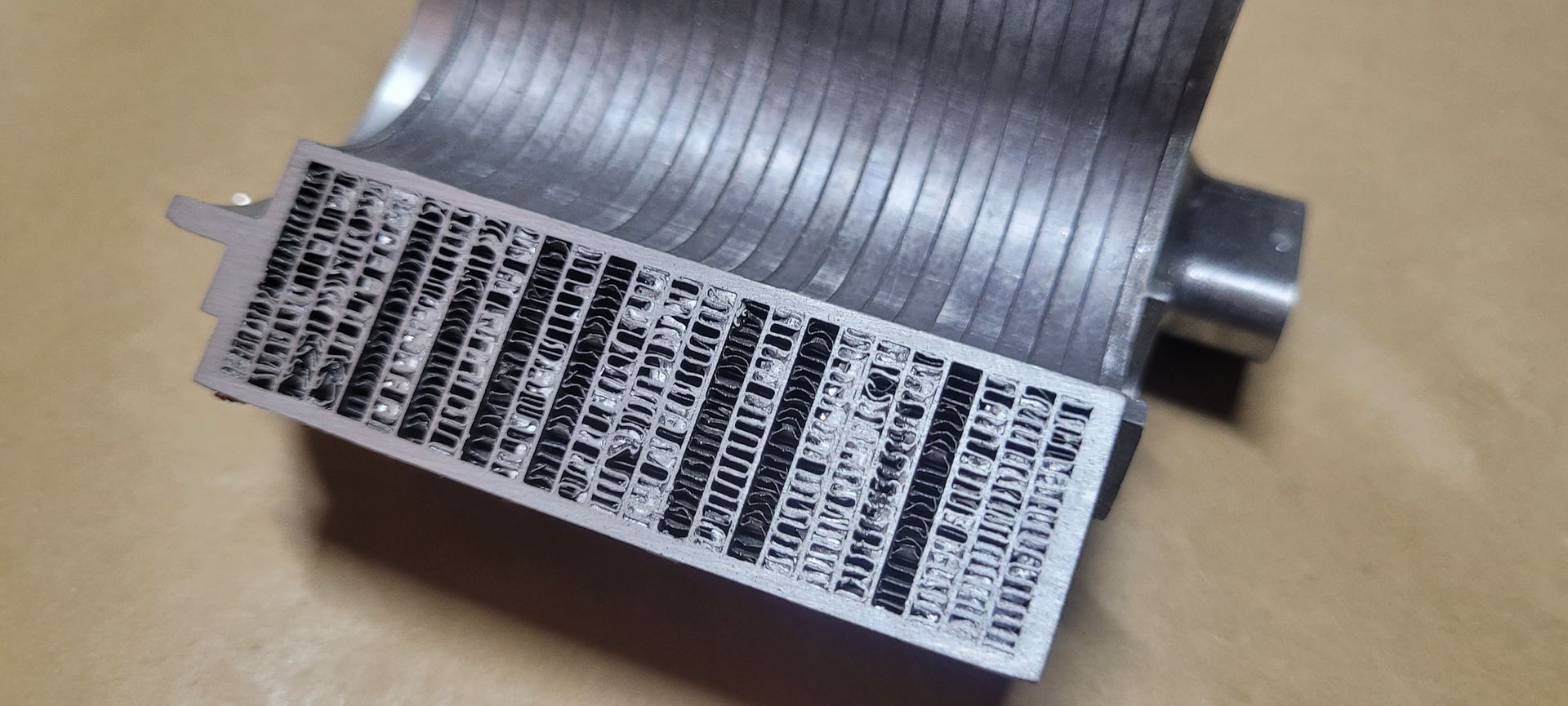

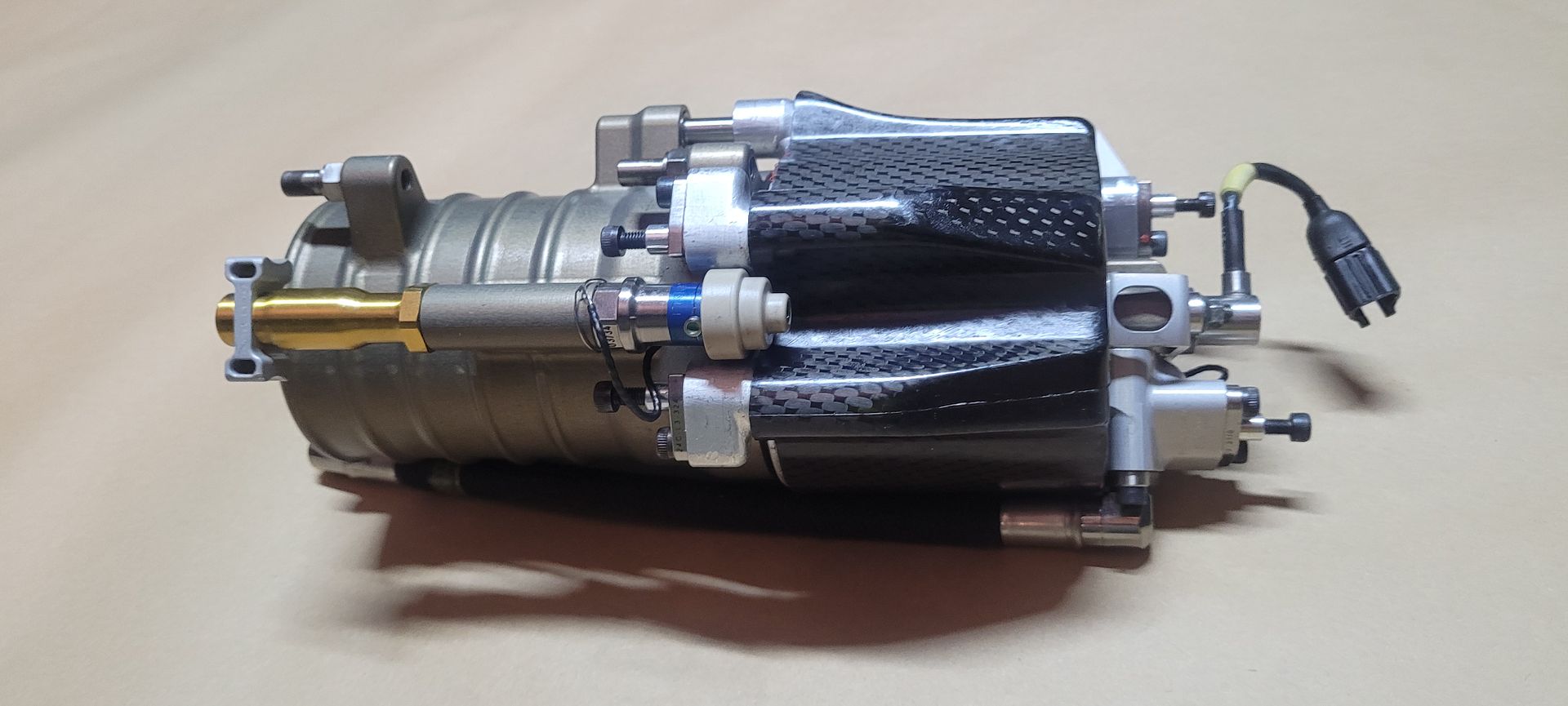

The main body appears to be Type III hard coat anodized 7xxx series aluminium alloy, the outside is left as is post anodizing however the interior bore appears to have been sealed with ptfe and honed - which will be seen later,

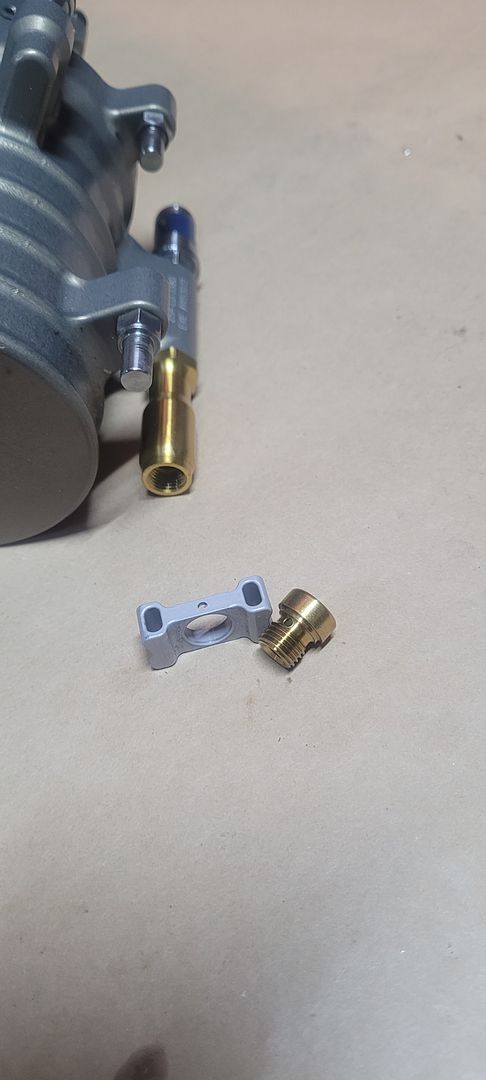

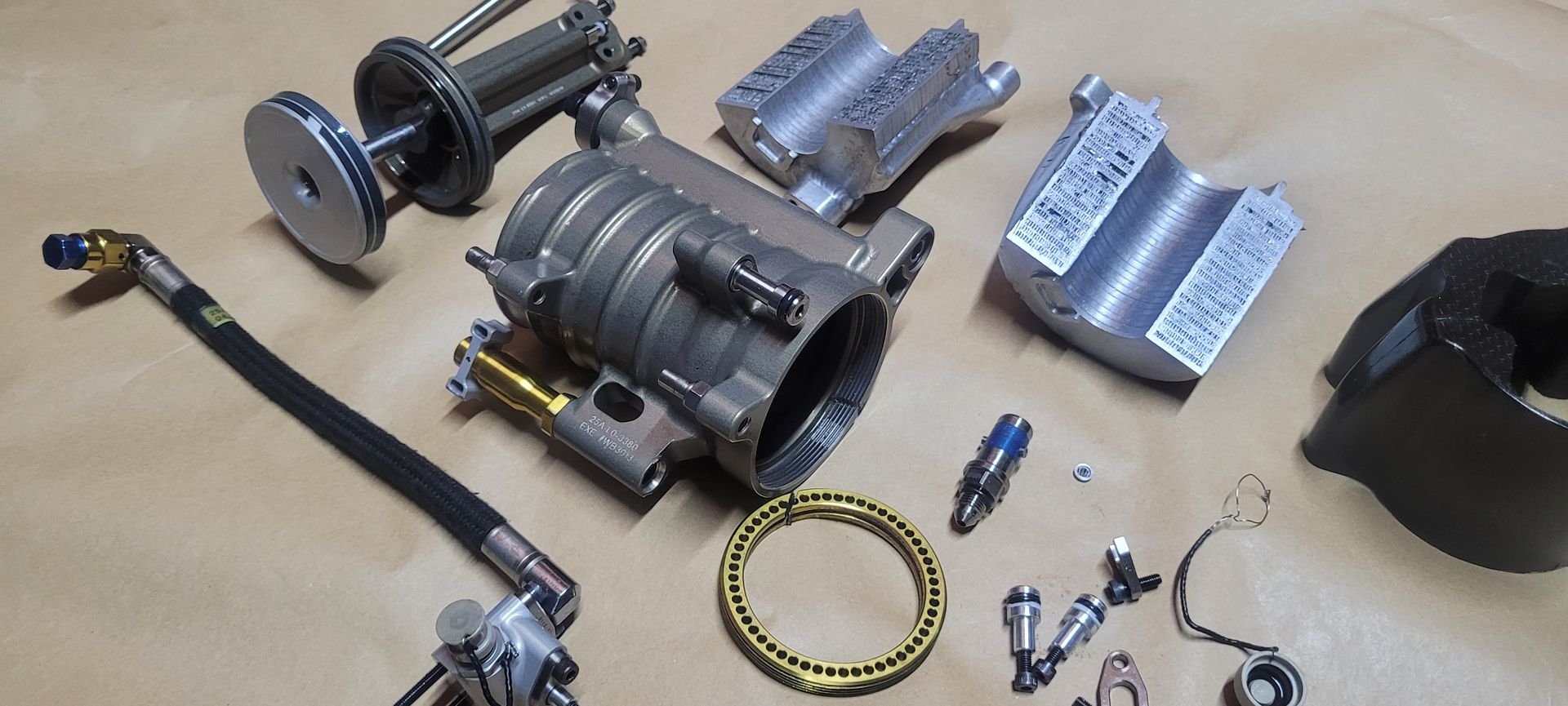

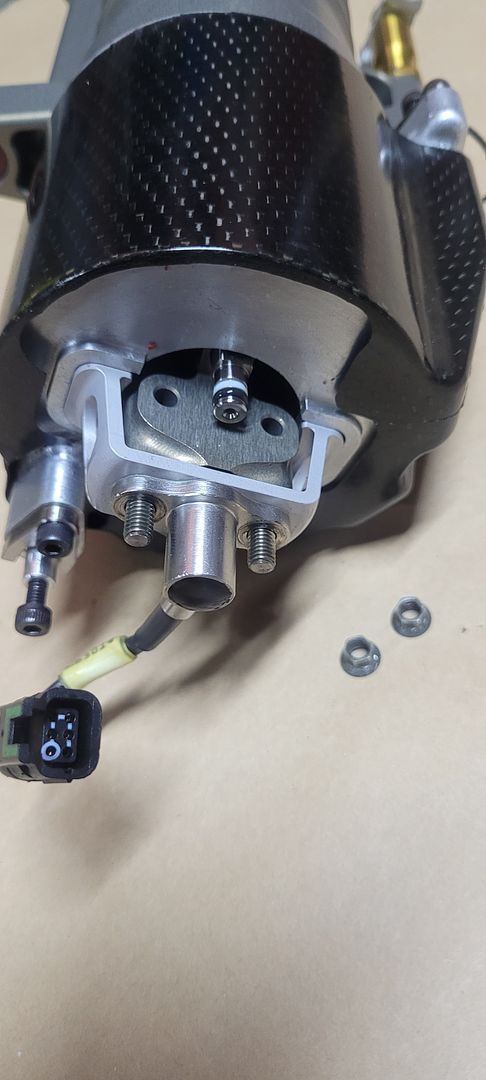

The oil manifold was first removed in order to be able to slide off the carbon fiber cover,

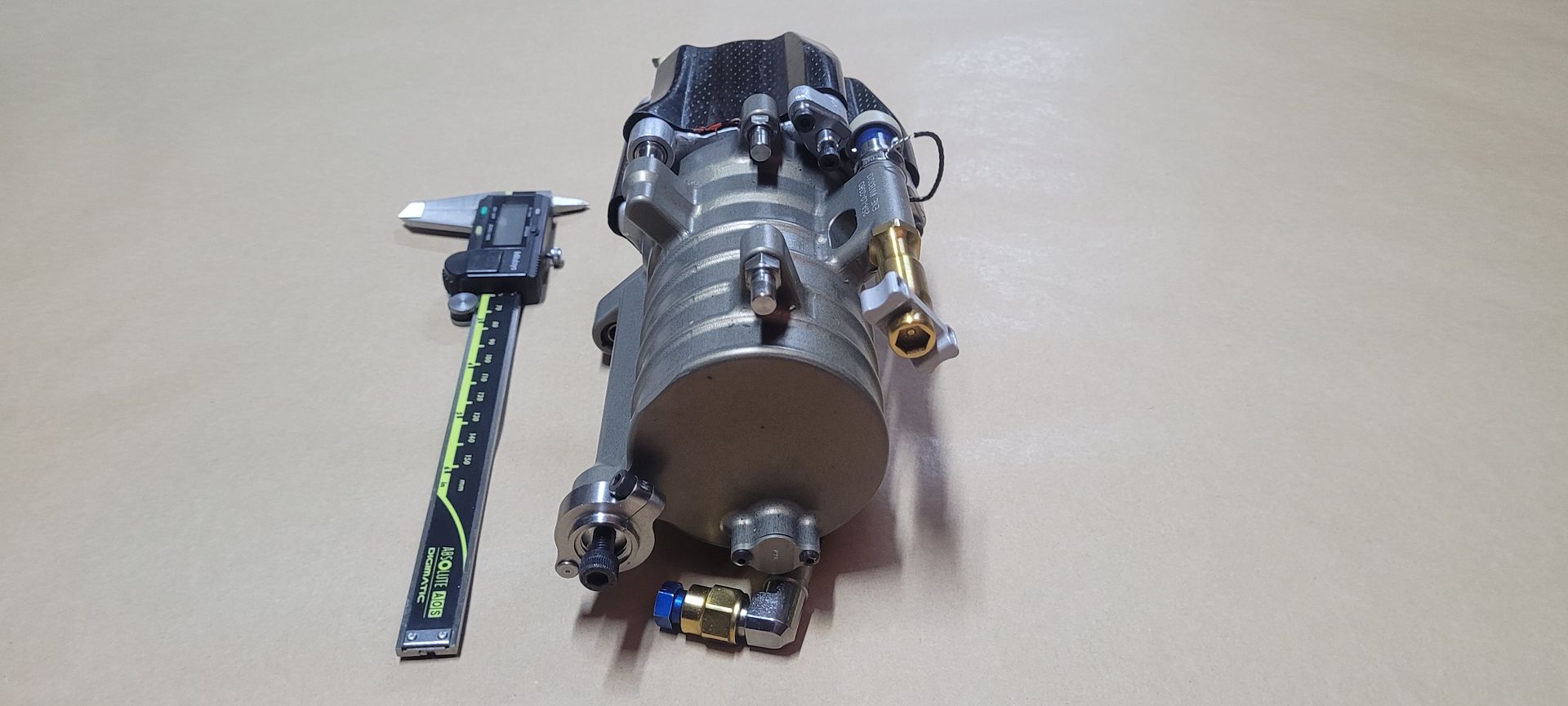

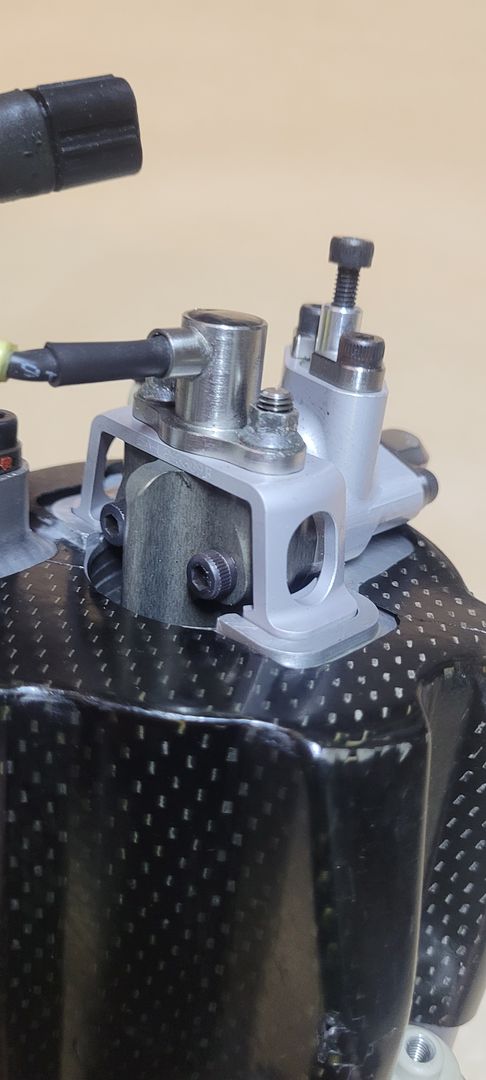

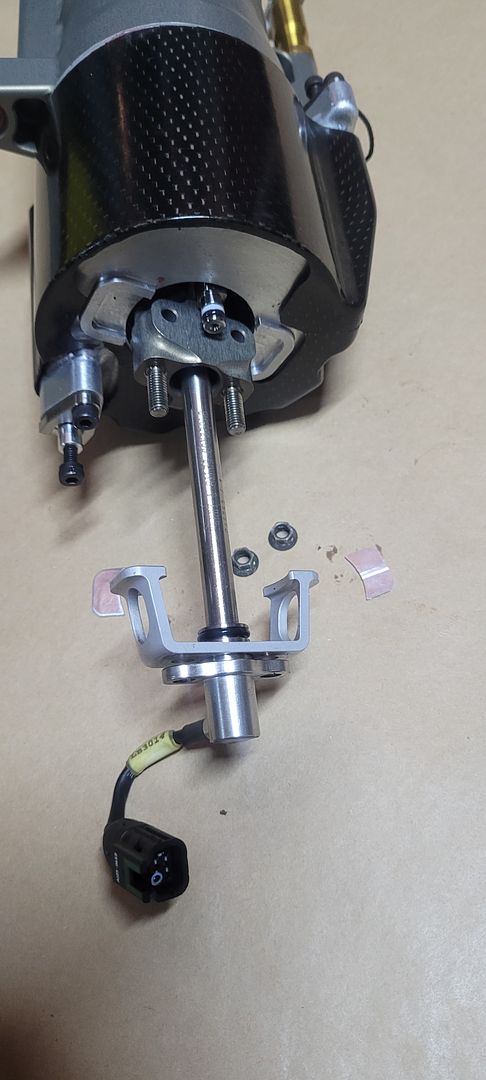

The bridge carrying the linear displacement transducer was then removed, this sensor accurately measures the position of the piston within the accumulator body. The sensor is from Penny and Giles,

Take note of the two small shims that were under the sensor bridge - these are required to accurately calibrate sensor end position vs piston max travel position. This deviation is caused by tolerance stack up due to it being mounted onto the oil to water heat exchanger which is a weldment/diffusion bonded item,

The internal traveling part of the transducer can now be seen deep down in the accumulators piston rod,

With those parts out of the way the carbon cover could now be removed, it is held on with RTV Silicone in a few areas,

Worth noting this is the thinnest carbon part I've ever come across, as light and as fragile as a paper cup,