Hello guys, a couple of friend and I decided to build a dune buggy. We are going to design the front and rear suspension. Front is double A-arm, with a fiat 600 upright. Rears is mc-pherson with fiat 128 upright.

It will have a 1.3 liter engine from a fiat 128. The project is quite cheap, a first project. Nothing really extravagant, nor to jump 100m. A tough dune buggy that will climb and tolerate some small jumps.

I would like to know which should be our goals in term of suspension movement.

For the moment I'll focus on the front of the car.

For example wheel travel. 40cm is enough? Of that 40cm, I guess we would need 25cm for bump, and 25cm for droop, is that logical?

Should we minimize camber variations(i.e. long a-arms), bump stter(short steering rack)?

What's a logical wheel steering angle?

I have some basic idea, but I've never worked with dune buggy's so I don't know where to aim, yet. Anything you have to add, advice or whatever is more than welcomed.

Thank you very much!

Caito.

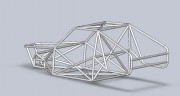

PS As soon as I finish suspension design I'll start buggin' with chassis :p

- Login or Register

No account yet? Sign up