Tech Analysis: Ferrari SF16-H

Ferrari was the first team to make a public unveiling of their actual car, fully aware that a proper launch still can draw some much needed attention to a team. The presentation was in fact one of the best seen in recent years, with a view on the car, a technical explanation and the marketing talk cut short. All good it seems.

On the technical side, Ferrari appear to have made proper efforts to make sure it was going to make a considerable step forward, hoping to keep challenging Mercedes AMG F1 for the title, until the very end of the season. That should theoretically not be a problem, given the team's increased budget, and James Allison's efforts to streamline Ferrari's working processes to claw back from an extremely disappointing 2014 season.

The car, until its launch dubbed project 667, has involved 700 people at Maranello, plus that of external suppliers that worked in cooperation with the Italian team, especially on the power unit. Technical director James Allison added the team mainly worked on optimising the use of the Pirelli tyres while trying to get the maximum possible downforce. To achieve the latter, more than 1500 hours were spent in the wind tunnel.

The first look on the SF16-H immediately shows that the team has not been hesitant to take a close look at competing cars in 2015. Certainly on the chassis side, Ferrari have taken design cues from Mercedes and Red Bull, especially in the design of the sidepods and the nose cone.

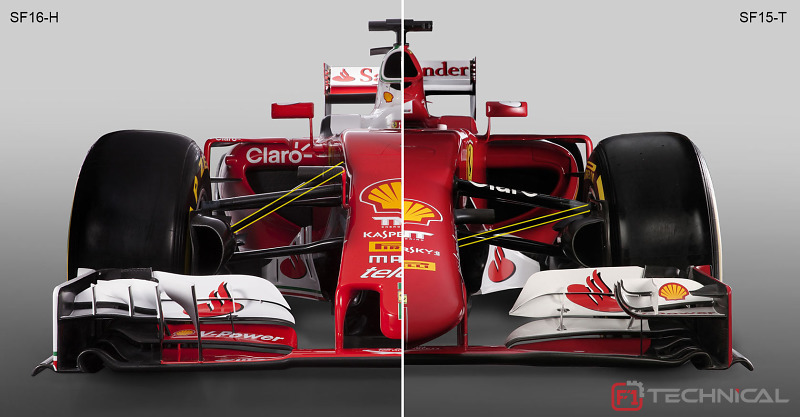

Changes at the front

At the front of the car, it is immediately obvious that Ferrari have dumped the long nose layout in favour of a short, thumb style nose. A consensus appears to be forming among F1 teams that this is simply the best solution, even though it is quite a bit harder to get through the frontal impact tests than with a long design. Additionally, it may come with some additional drag, and that is exactly why teams are trying to increase the gaps alongside the thumb. The straight on airflow that this enables is much more efficient than pulling air underneath the nose that passed on the outside of the front wing pylons. Many variations of this concept exist, but all aim to maximise undernose flow while trying to be as close to the regulatory limits as possible.

Perhaps the most important change compared to 2015 is Ferrari's decision to revert to a more conventional front push rod layout. Ever since the introduction of their front pull rod it had been a major point of discussion with questions being asked if it was a viable solution at all. The team did of course win numerous races with it, but the low nose regulations may have forced the team's hand. In 2015, the team only just managed to position the suspension elements onto the chassis, with the upper front wishbone very close to the upper front corners of the monocoque.

In contrast, the new layout sees the wishbones run much more horizontal, with the front wishbone pickup point at least 5cm lower than before. This move is actually in line with front suspension design decisions made by other teams since 2014. The new layout thus has a lower roll centre and less built-in anti dive. As can be seen from the comparison, the team did manage to reduce the thickness of the upper front wishbone to shed drag and weight.

As marked in the image, it is also clear that the upper nose cone fastener is now above the upper suspension arm, which in turn should make changing a front wing easier as well.

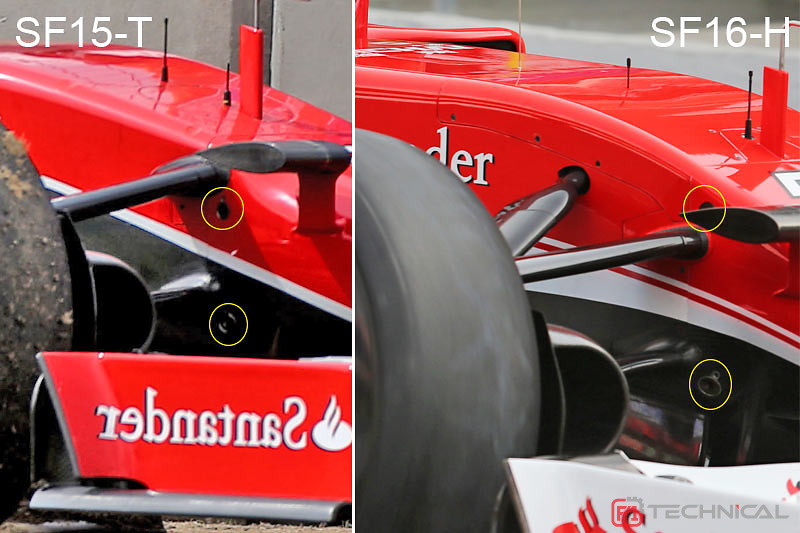

Moving on to the cockpit area, Ferrari have obviously also had to raise the side protection around the driver's helmet by another 20mm. Behind the driver, the airbox has received some further aerodynamic sculpting, with the inlet slighly more rounded, and behind it a narrower cover, likely made possible by changing the engine air intake duct. The launched specification also retains a winglet that is seemingly aimed at creating vortices at its wingtips to enhance rear wing performance.

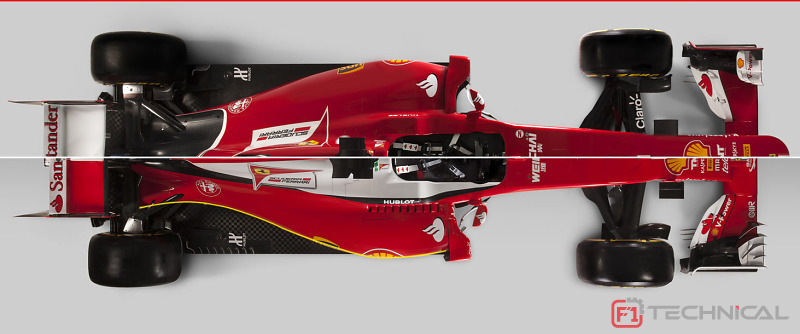

Rear packaging

The sidepods and the rear of the car have also been tightened quite impressively. The sidepods for instance now feature a near linear downward slope of the upper surface, from the inlet to the outlet, whereas the leading part used to be higher. The new SF16-H also has its hot air exits higher above the floor than before. This clears up quite a bit of clear space underneath, enabling more quality airflow to pass alongside the gearbox housing and over the diffuser. An interesting side effect of this is that the sidepods generate less lift on their own.

Looking at it all from the top, it is clear that the car is much narrower at the back than before, with the shape narrowing before widening again to help extract hot air from within the sidepods. It's not dissimilar to some recent cars produced by Red Bull Racing, and no rocket science on its own, but it does of course require compact packaging of the car's internals.

This intenal packaging improvement is mostly the result of the power unit team, as several engine components have been relocated. As the team opted to incorporate variable length inlet trumpets for the first time this year - a certain improvement in combustion efficiency across the power band, the added volume for these trumpets forces the team to move their air-to-water intercooler from within the engine's V to two seperate elements, one ahead of the engine, just behind the driver's head, and one low down in one of the sidepods. Additionally, the ERS-K motor was moved forward, from inside the gearbox housing to being attached on the side of the engine block, mimicking the layout of all other power unit suppliers.

Finally a word on the new exhausts, where Ferrari have opted for combination of one main exhaust pipe with two wastegate outlets, positioned underneath the main pipe and fairly distance from each other.

All in all, Ferrari have incorporated considerable changes into their package, something that is not always evident in a time of fairly stable regulations.