Just to be clear, this is just the leading theory at the moment because of the B Sport video (it also makes sense). However, it is not exactly confirmed that's exactly what they're doing there, so for all we know, it could be something else.

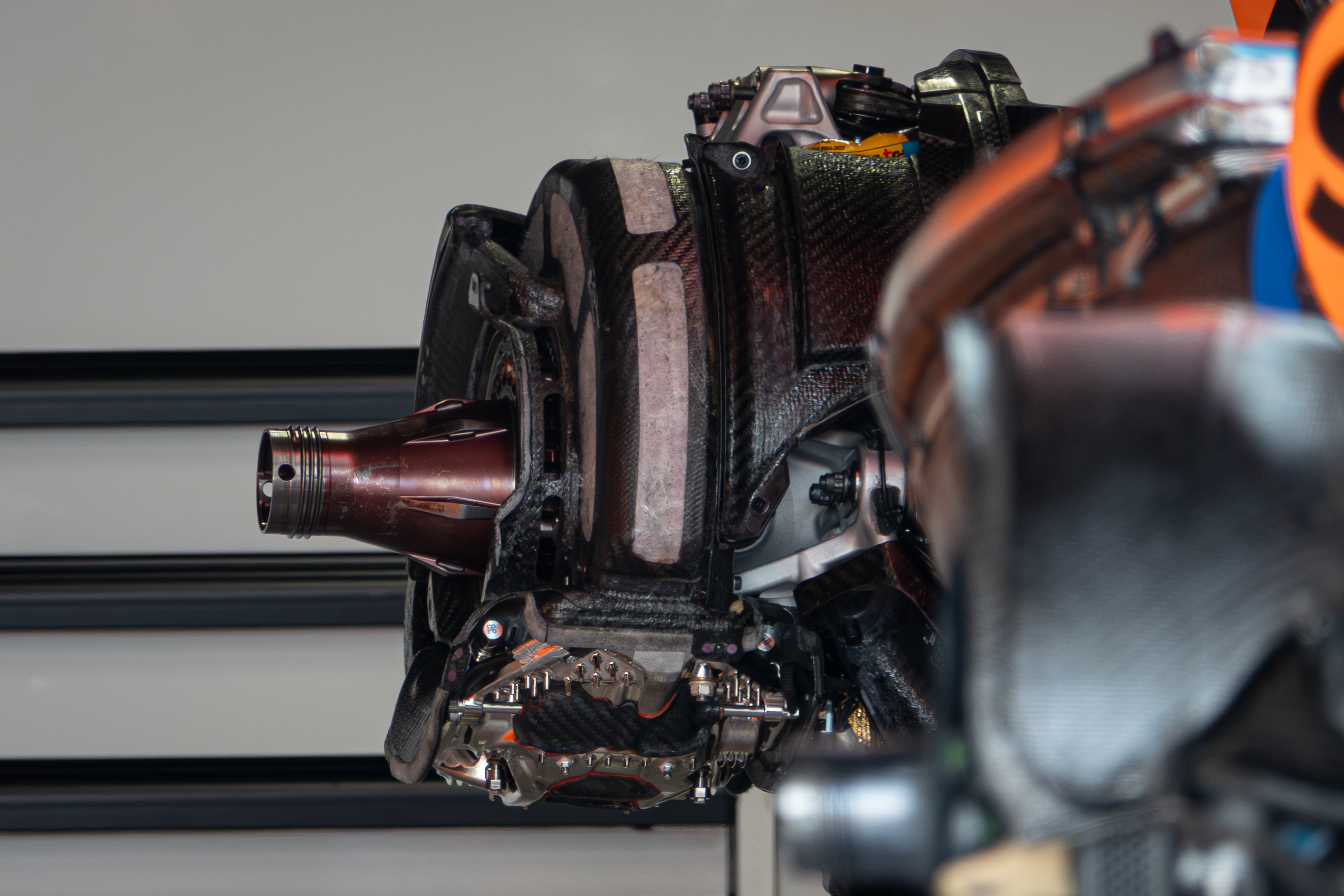

After it popped up, the topic was really intriguing and I tried to do some personal research on it. After reading a bit more, it sounds really difficult to pull off, but I am also not aware of recent advancements that might have happened in the field to negate some of the issues I could see with it during my reading. There's too many technical challenges one needs to go around to integrate this successfully, because the area of application (inside the cake tins) is really tricky and limiting, both in spatial and environmental factors. Apart from worrying on getting the benefits out of it, you need to be careful not to mess up the primary purpose of those parts, which is to manage brake temperatures.

Considering the limitations previously mentioned, you would definitely be forced to run an extreme solution with potentially really thin PCMs which kind of creates more problems in terms of reliability, because if something fails in the system and you get some sort of "leakage", it could potentially be catastrophic / race ending.

Now, Lando did have that brake issue in China, but I am not sure if it was related to the rear brakes specifically, or if it was a generic hydraulic failure. Nevertheless, just one failure is not enough to conclusively prove PCMs use.

Apart from the technical challenges, there's the regulations to consider as well. And to be honest, even after reading the relevant articles on the technical regulations documents for last year (not sure if the 2025 ones are available), it's quite difficult to pinpoint whether or not use of PCMs is legal or not. An argument could be made for both, however using SSPCMs (Shape-Stabilized PCMs) could definitely help to avoid some "liquid cooling" problems, which aren't permitted. SSPCMs don't melt like traditional PCMs so it helps avoid reliability issues I mentioned as well, however their latent heat storage capacity is not as great, potentially rendering them ineffective for this use case. But I haven't made nearly enough research on the topic to make that claim with confidence.

Legality issues aside, there's something else to consider from the technical regulations that might make a solution like this quite ineffective as well. Specifically, the following segment from

article 3.13.2 Drum :

For each drum, a circumferential, continuous (around an arc of 360°), and uniform

aerodynamic seal must be fitted in the outboard of the two annotated volumes, in order to

prevent any significant aerodynamic or heat transfer flow between the drum and the axle.

This restricts the already tight space you have to work with even further.

In addition, the adjacent article 3.13.3 on the Scoops has a list of multiple legality box constraints which are an absolute pain to work out specifically, but I can't imagine introducing a new sheet of different material in there doesn't comply with at least one of them, which makes the integration even trickier.

Long story short, it's a really cool subject that got me reading into it. It's also a really complex thing to get right for this sort of application. Not only for it to be legal, but also to provide benefits without sacrificing reliability or braking performance, however I would not put it past F1 engineers to figure stuff like this out. I really love intricate ideas like this. If this is indeed what they're doing, is really really impressive. But as I mentioned, we might be getting a little carried away here. Sometimes (not always), things are simpler than they look. Although I have zero clue how else they would have managed to create such an efficient temperature management solution that seemingly has the rest of the grid stumped as well.