Seals for the Watson rotary valve engine were said to be inspired by the simple Belleville disc spring seal - with the added detail of being made in a wafer/wave profile - hand made on a wood die in Watson's workshop - as I understand the article. Could sealing a rotary valve really be that simple? This was in 1987 before a lot of current coating technology would have aided the problem:

http://www.keybellevilles.com/apps.html

http://www.bellevillesprings.com/disc-s ... ption.html

Oil consumption for the 1000cc engine was one liter every 5000 miles.

The BSA sports-car was raced in over 2 dozen venues.

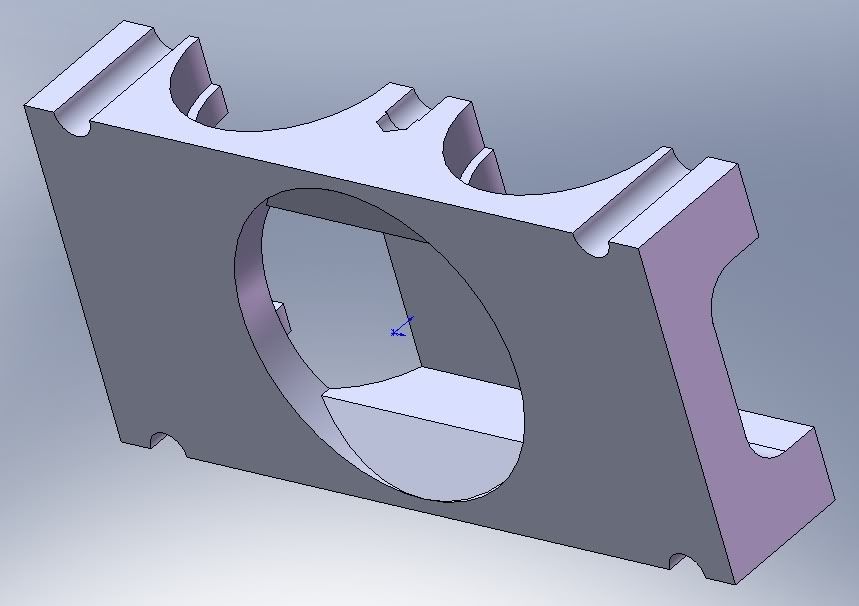

The head looks to be dry deck. The BSA was air cooled and so were the heads.

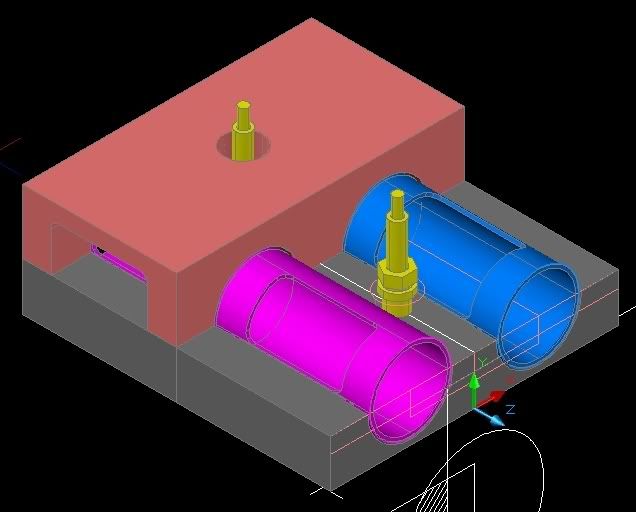

rotaryvalveman's combustion chamber design closely follows 2 stroke design, a double squish disk shape, with the addition of lozenge shaped ports.

I have a great deal of respect for Ralph Watson, especially as he designed and built by himself. Seeing his barn tool shop, this was no high tech effort, instead craftsmanship and engineering acuity, very old school, a lot to admire. Back in the 0's there was still a lot of garage projects. I remember several covered by Cycle World , a 500cc V8 using Honda 50 barrels and heads. A 250cc Ducati stretched to 350cc which inspired the factory to follow suit, in the 70's the 50cc GP class had a lot of garage enterprises, producing engines, I remeber a lot of aluminum monocoque chassis. It would be interesting to have access to Mr Watson's work. Reading through links, he had a life long involvement with aeroplanes, cars and boats, the articles impress that he was well regarded as a friend to those that helped commit his work to print. Passed away in 2006 at 94.