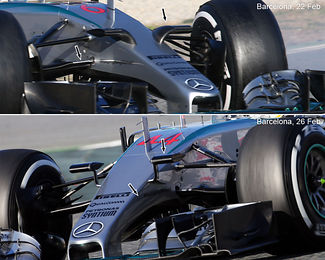

Alpine already switching to more compact rear end

Lots of people were stunned by Alpine's decision to fix a bulky airbox on the A521, but the team have already run their new car today with a new, more compact design that sees the rear end of the car considerably slimmed down. Along with the airbox that now tapers down more more quickly, the sidepod air outlets are smaller, leaving a lot more room low above the car's floor for clean airflow.

As the image shows, Alpine were focusing on front end aero on Friday morning with a rake fit... Read more